Supercritical carbon dioxide dyeing system and process

A carbon dioxide, dyeing system technology, applied in the field of dyeing, can solve the problems of not meeting the needs of color diversification, reducing enterprise benefits, wasting resources, etc., to increase automatic operation devices and cleaning processes, improve intensification and automation, and meet diversification effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

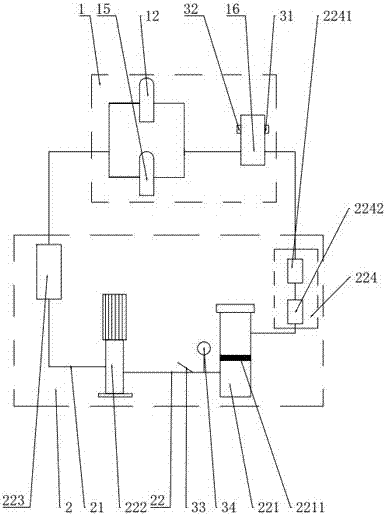

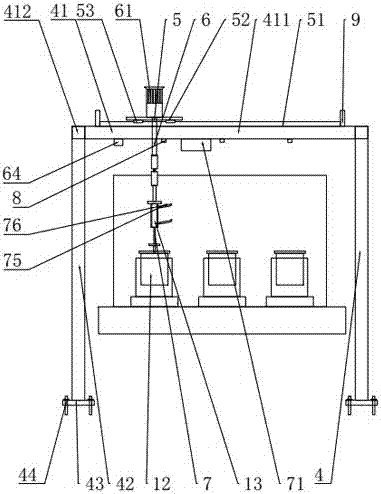

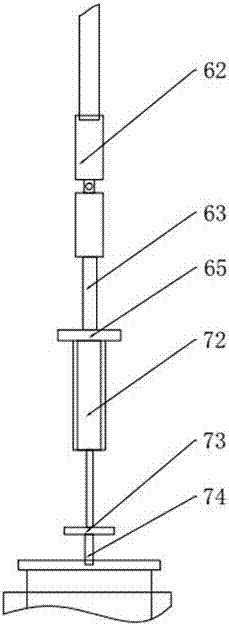

[0074] Such as figure 1 As shown, the present invention provides a supercritical carbon dioxide dyeing system, comprising: a dye mechanism 1 and a carbon dioxide dyeing system 2, the dye mechanism 1 includes an extraction device 11 and a dyeing device 14, and the extraction device 11 includes a vegetable dye extraction kettle 12 and an automatic extraction kettle Operating device 13, dyeing device 14 comprises natural plant dye still 15 and dyeing still 16;

[0075] Vegetable dye extraction kettle 12 and natural vegetable dye kettle 15 are arranged in parallel in carbon dioxide dyeing system 2, and the input end of dyeing kettle 16 is connected with the output end after plant dye extraction kettle 12 and natural vegetable dye kettle 15 are connected in parallel, and the inner wall of dyeing kettle 16 is Attached with 0Cr18Ni9 stainless steel coating;

[0076] In the foregoing embodiment, natural plants such as fresh flowers or dried flowers are put into the vegetable dye extr...

Embodiment 2

[0101] The dyeing process that adopts the dyeing system of embodiment 1 to carry out comprises the following steps:

[0102] 1. Prepare

[0103] 100 kilograms of cotton fibers are loaded into the dyeing kettle, 2 kg of rapeseed petals are loaded into the natural plant dye extraction kettle, and 0.5 kg of wormwood extract is loaded into the natural vegetable dye kettle.

[0104] 2. Preparation of supercritical carbon dioxide

[0105] The liquid carbon dioxide stored in the liquid carbon dioxide storage tank is injected into the high-pressure carbon dioxide pump through the pipeline; in the high-pressure pump, the carbon dioxide is pressurized to 8MPa, and then heated to 90°C by the preheater to obtain supercritical carbon dioxide.

[0106] 3. Extraction of natural plant dyes

[0107] The supercritical carbon dioxide fluid prepared in step 2 is injected into the natural plant dye extraction kettle and the natural plant dye kettle respectively from the preheater, and a part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com