Mobile phone antenna coupling test system and method on production line

A mobile phone antenna and test system technology, which is applied in antenna radiation patterns, transmitter monitoring, electromagnetic field characteristics, etc., can solve the problems of increased testing labor costs, difficult standardization of procedures, and a lot of time spent, so as to improve test accuracy and test efficiency , improve efficiency and accuracy, and improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

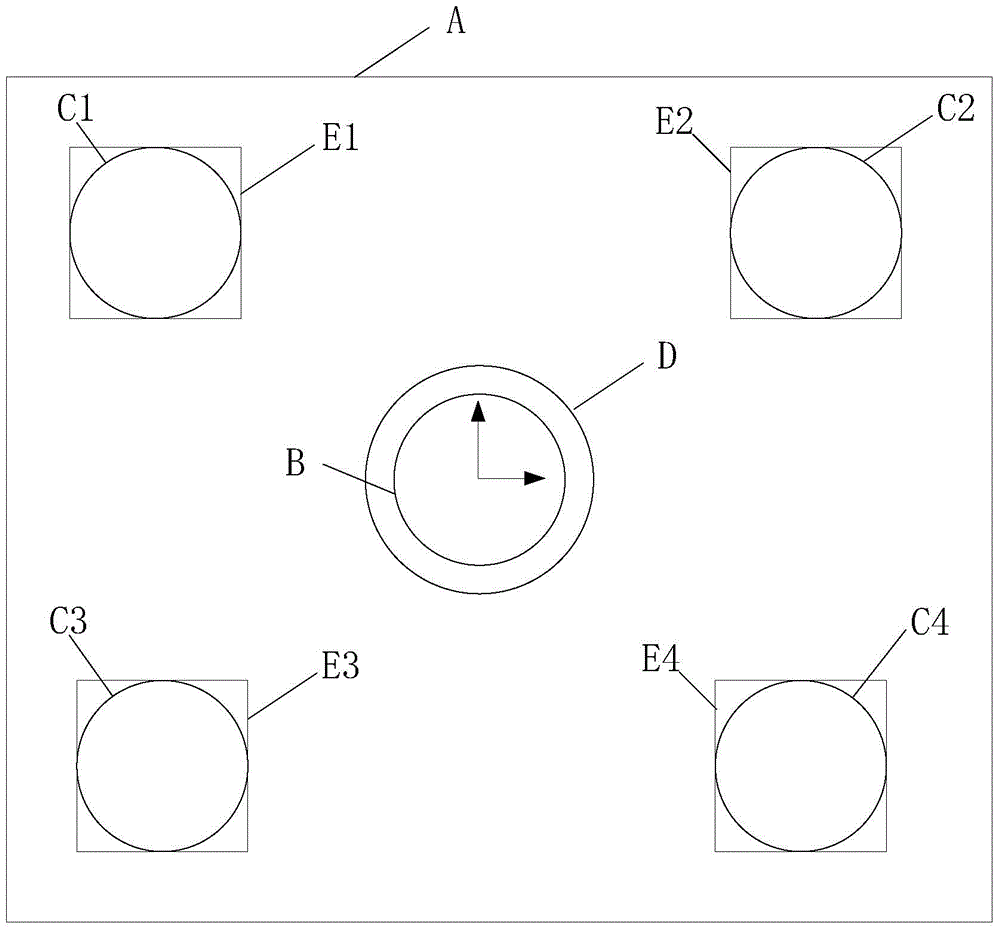

[0061] The invention discloses a mobile phone antenna coupling test system on a production line. The system includes: a coupling test module (software subsystem), an industrial computer, a multi-signal source device, a radio frequency cable, a combiner, and a coupling shielding box.

[0062] The coupling test module is the software subsystem of the present invention, and the industrial computer, multi-signal source device, radio frequency cable, combiner, and coupling shielding box constitute the hardware subsystem of the present invention.

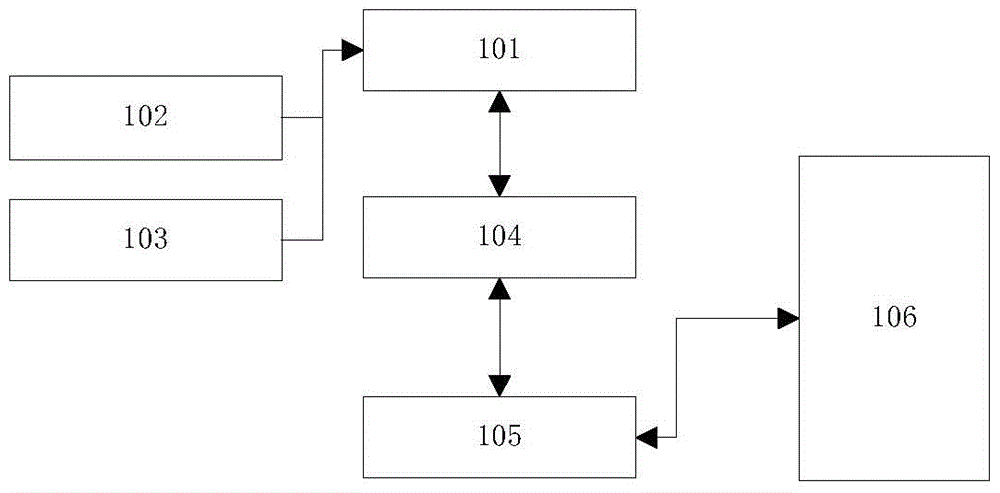

[0063] figure 1 Represents the system diagram of the system software sub-module MOS, 101 represents the UI module, and the mobile phone antenna couples the human-computer interaction, process and result display interface; 102 represents the graphics library module, providing various graphics management libraries for realizing 101; 103 is the font library, providing 101 The fonts required by the module; 104 represents the coupling test pro...

Embodiment 2

[0082] The difference between this embodiment and Embodiment 1 is that this embodiment discloses a mobile phone antenna coupling test system, which includes: a coupling test module, an industrial computer, a multi-signal source device, a radio frequency cable, a combiner, a coupling shielding box.

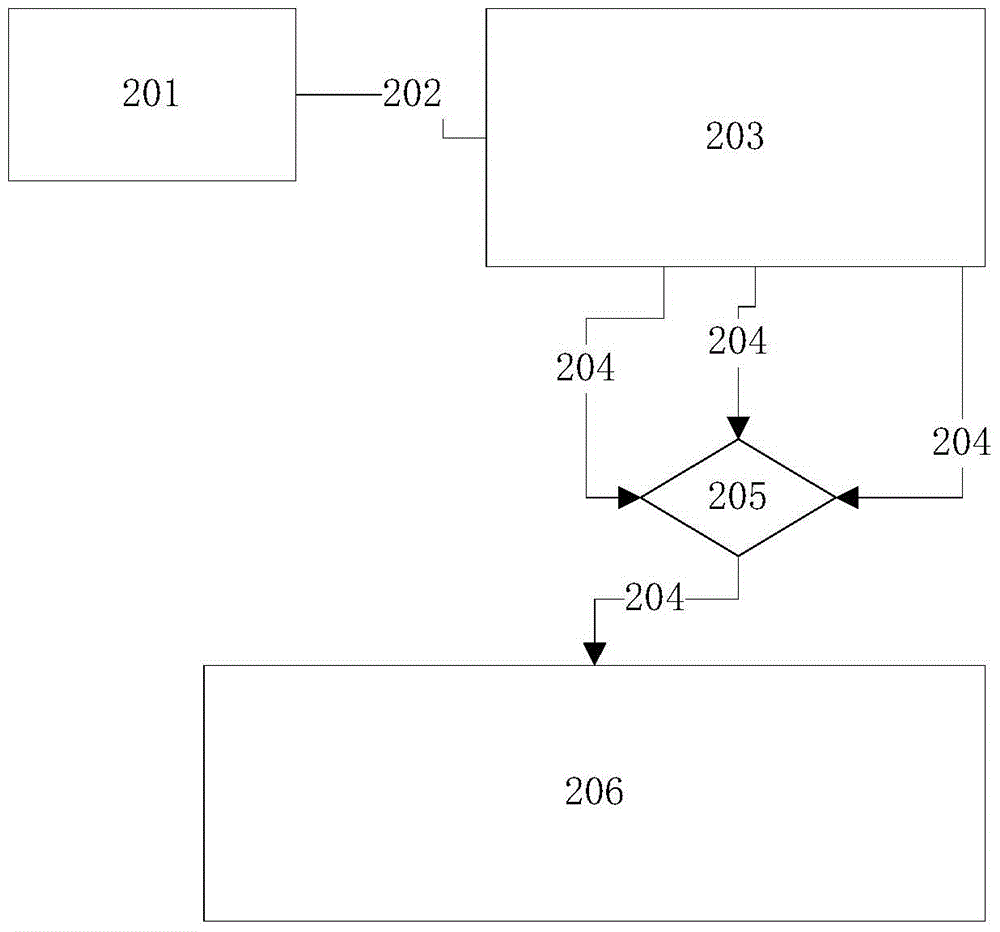

[0083] The coupling test module is a built-in test software of the mobile phone, which is used to set the coupling test of the mobile phone to be tested; the entire coupling test process is built into the mobile phone, and the physical layer of the mobile phone is directly controlled by the coupling test module to perform various basic operations and tests of radio frequency Action, test the radio frequency performance of the mobile phone antenna, and directly display the test data and test results through the mobile phone display. Coupling test module includes user interface UI unit, graphics library unit, font library unit, coupling test processing unit, drive library unit, inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com