Smart Fuel System

A fuel system, intelligent technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve problems such as reduced work efficiency, equipment aging, equipment diagnosis and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

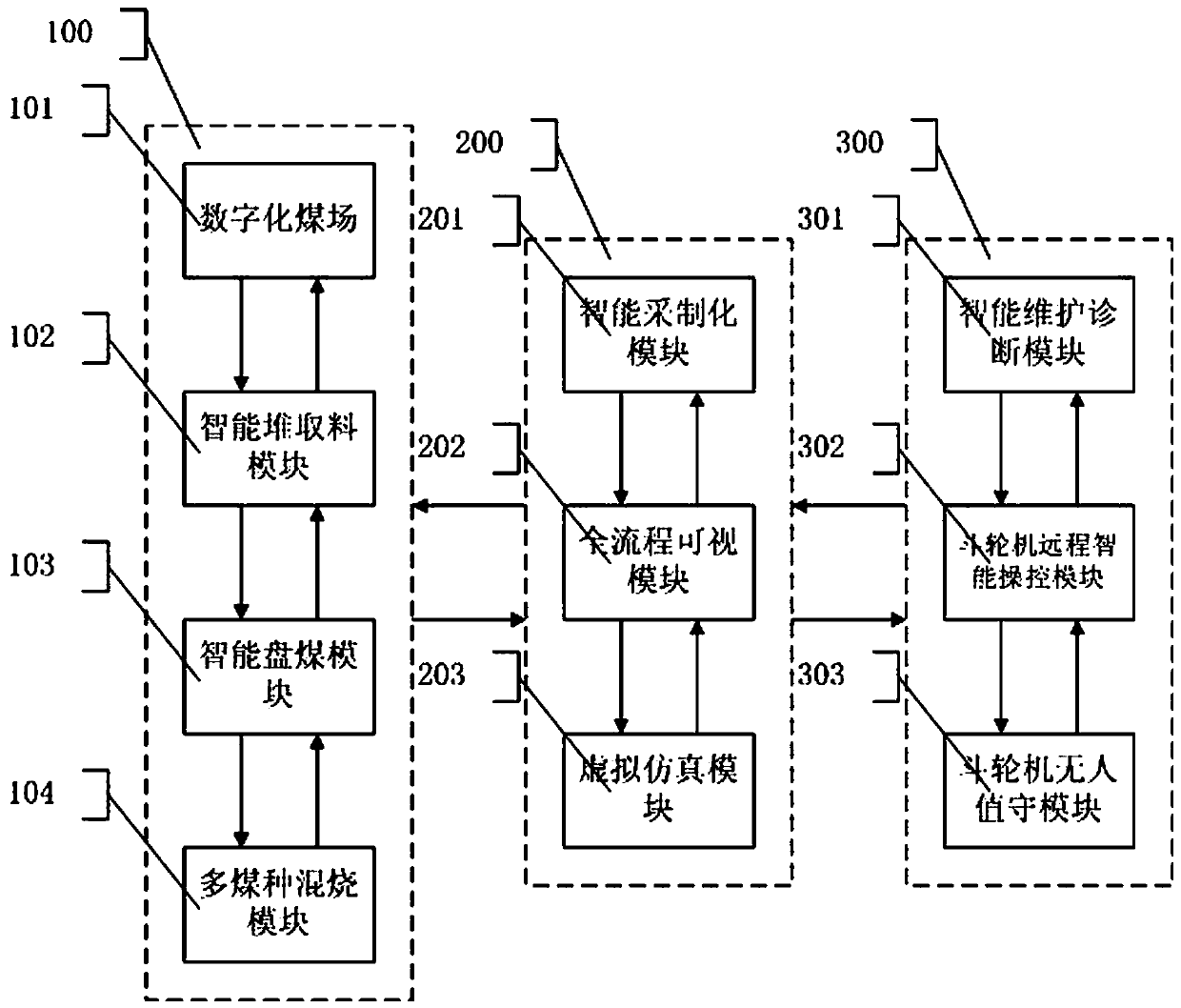

[0044] Such as figure 1 As shown, the fuel subsystem 100 includes a digitized coal yard 101 , an intelligent stacking and reclaiming module 102 , an intelligent coal panning module 103 and a multi-coal mixed combustion module 104 . The digital coal yard 101 is used to display the real-time situation of the coal yard and the situation of coal in and out. The intelligent stacking and reclaiming module is used to arrange the location of the coal according to the properties of the coal, and arrange the optimal coal taking plan according to the coal situation. The intelligent pan coal module is a multi-point density and density-coal intelligent relationship library established by using drones to take inventory of coal yards, which strengthens the accuracy and security of data, and strengthens the traceability of data. The multi-coal co-firing module 104 is used to determine the optimal co-firing scheme according to the quality of coal to reduce costs. Improve efficiency. The disp...

Embodiment 2

[0046] The intelligent fuel system includes: digital coal yard, intelligent stacking and reclaiming module, bucket wheel machine unattended module, bucket wheel machine remote intelligent control module, intelligent coal pan module, whole process visual module, multi-coal mixed combustion module, intelligent maintenance and diagnosis module, virtual simulation module, and intelligent procurement module.

[0048] The digital coal yard module can use the 4D function to truly, real-time, and accurately display the three-dimensional map, plan view and expanded view of the coal yard, as well as the coal storage information of the coal yard (including storage location, coal quality, stacking time, coal pile angle, coal pile density, Coal pile weight and other information), it can depict the coal weight and coal quality of each zone and layer of coal storage in the coal yard, and the traceability function is added through the time axis, and a certain typ...

Embodiment 3

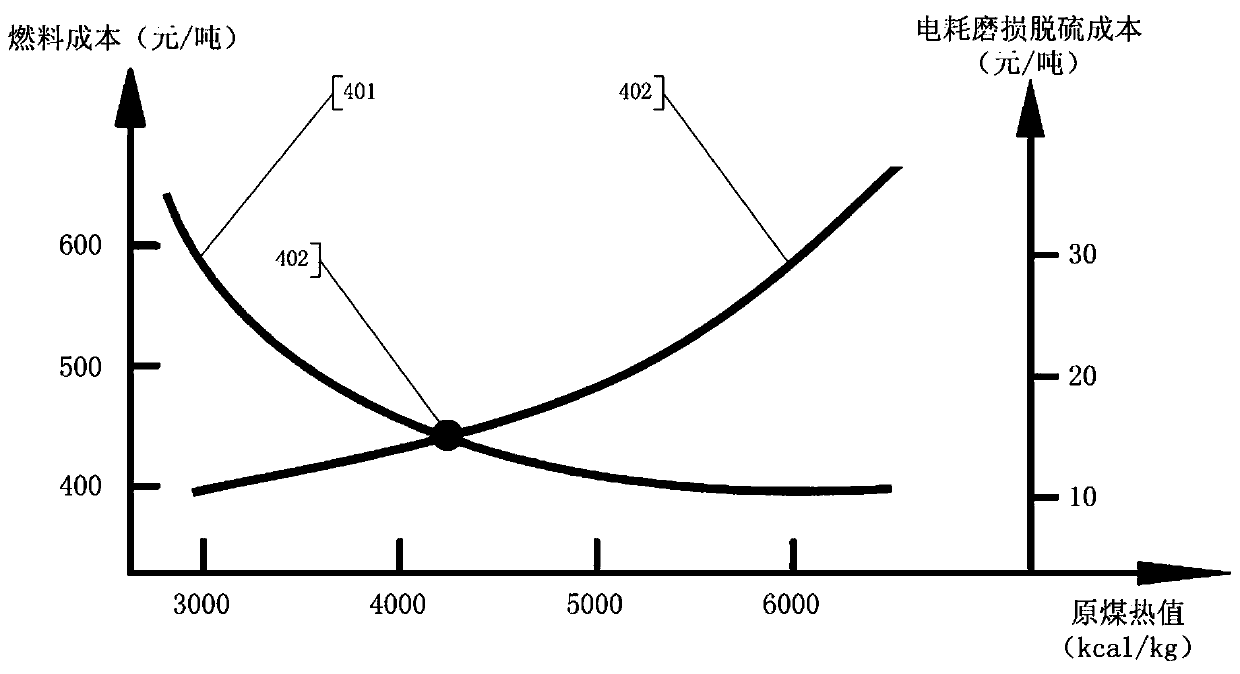

[0079] Such as figure 2As shown, the label 401 is the relationship curve between good point wear desulfurization and coal quality, the label 402 is the relationship curve between incoming coal cost and coal quality, and the label 403 is the balance point of the two curves. Refined combustion blending needs to determine the quantitative relationship between coal procurement cost and unit operation economy, seek the balance point between fuel price cost and operating cost, turn qualitative analysis into quantitative analysis, and obtain the unit fuel cost and incoming coal The relationship between calorific value to realize the value optimization of the unit power output cost of the power plant.

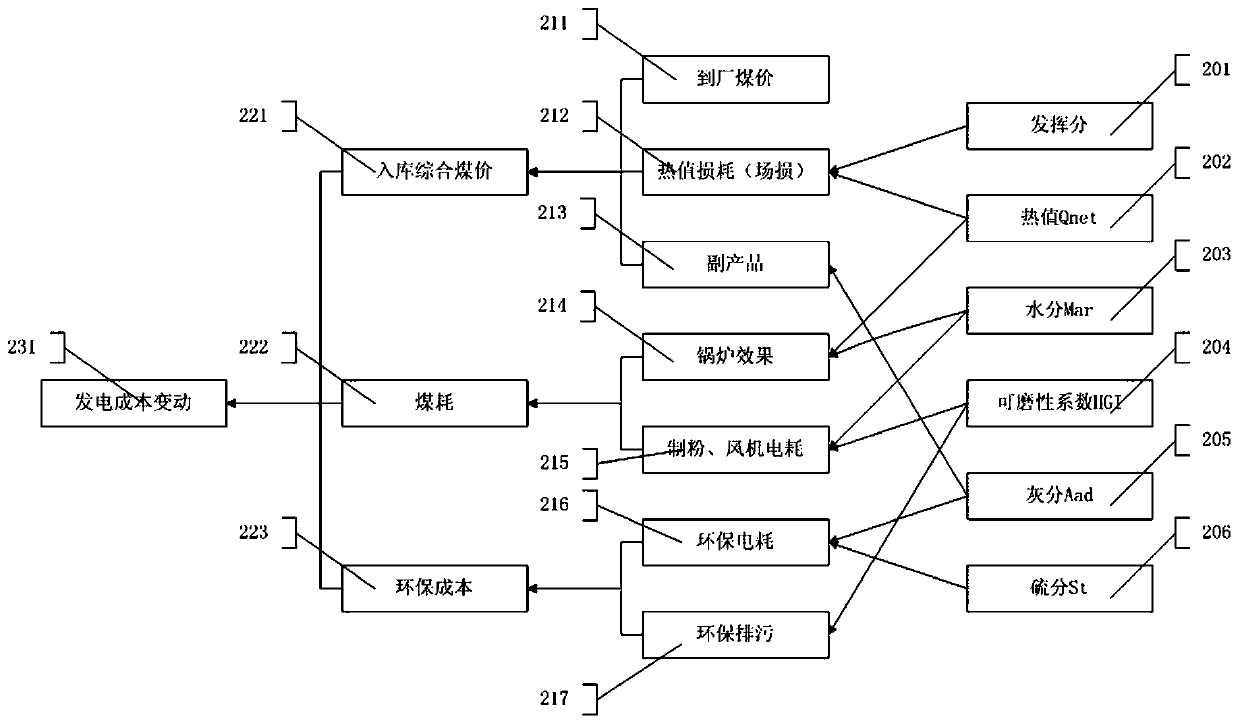

[0080] Such as image 3 As shown, the exertion score 201 and the calorific value Qnet202 have an impact on the calorific value loss (field loss) 212, the ash content Aad205 has an impact on the by-product 213, the calorific value Qnet202 and the moisture Mar203 have an impact on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com