Cooling system based on phase change microcapsule liquid pulp cold storage device and operation method

A technology of phase-change microcapsules and cooling systems, applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as input power consumption and affecting the overall efficiency of system operation, and achieve power consumption reduction, The effect of increasing apparent specific heat, improving efficiency and energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

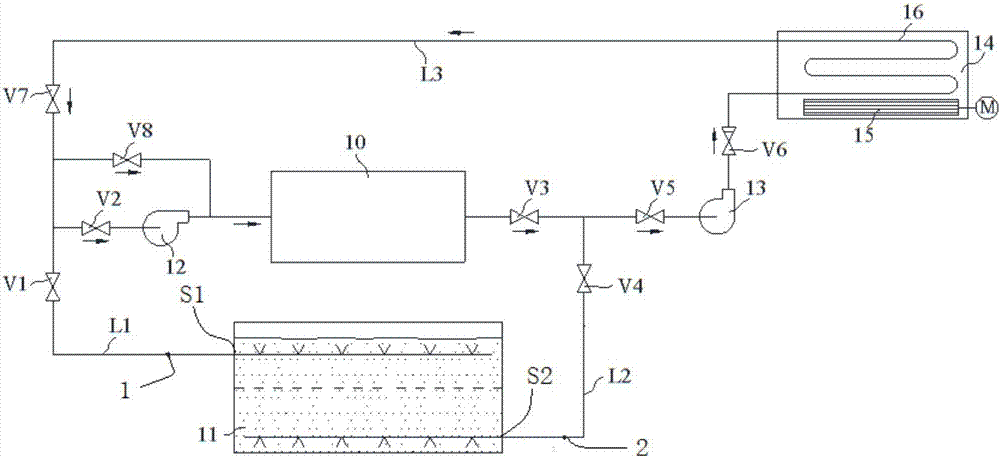

[0025] Hereinafter, the system components and various operating modes of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the following descriptions are only preferred specific embodiments of the present invention, and any modifications or changes made without departing from the essence of the present invention shall fall within the protection scope of the present invention. Accordingly, the drawings and description are illustrative only and not restrictive.

[0026] This system uses the phase change microcapsule slurry as the storage and transmission medium of cold energy in the cooling system. The system directly uses the liquid slurry to exchange heat with the evaporator in the refrigerator for charging and cooling, and also directly transports the liquid slurry to the fan coil unit of the indoor user terminal 14 for cooling without intermediate secondary heat exchange links. The preparation method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com