Temperature and strain velocity controllable aluminum alloy compression deformation device and testing method

A strain rate, compression deformation technology, applied in the direction of temperature control, using stable tension/pressure test material strength, measuring device, etc., can solve the problem of inability to meet the requirements of mechanical experiments, inaccurate strain rate control, and small ingot size. and other problems, to achieve the effect of wide application, easy assembly and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

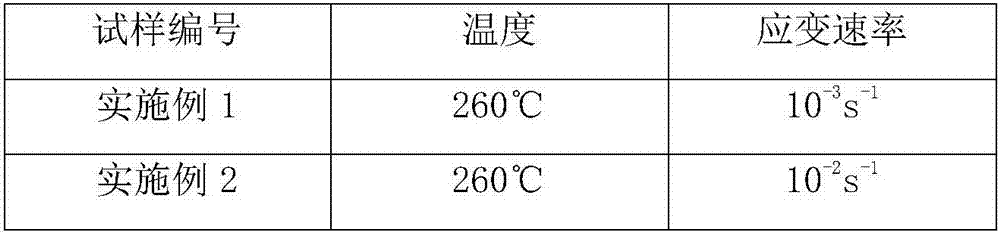

Examples

Embodiment Construction

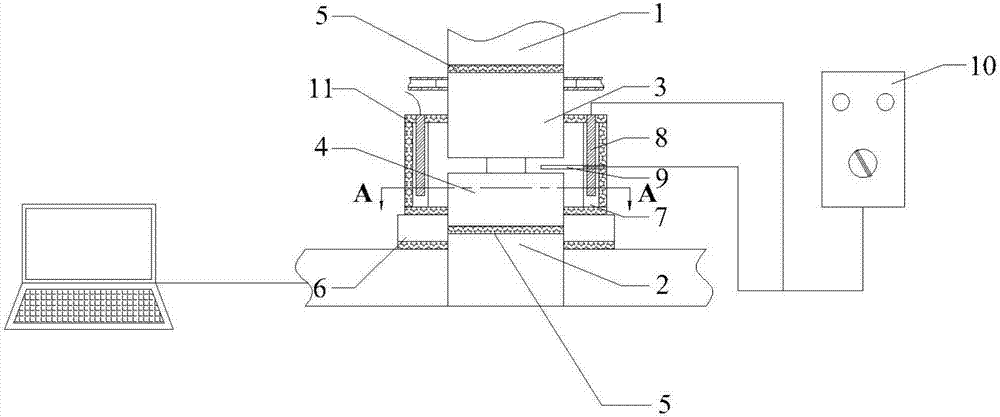

[0027] Such as figure 1 As shown, the temperature and strain rate controllable aluminum alloy compression deformation device of the present invention includes a strain rate controllable loading device, in addition to a temperature controllable heating device.

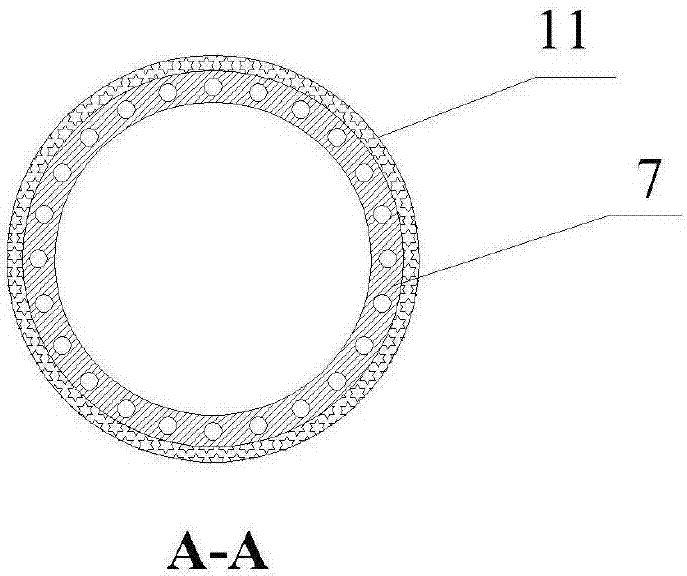

[0028] The loading device with controllable strain rate is a universal testing machine, including an upper indenter 1 and a lower indenter 2 . An external lower pressing head 4 is set directly above the lower pressing head 2 as an extension part of the lower pressing head 2; a heat insulating asbestos pad 5 is arranged between the outer lower pressing head 4 and the lower pressing head 2 to avoid direct contact. An external upper pressing head 3 with a force-bearing ear plate is arranged directly below the upper pressing head 1 as an extension part of the upper pressing head 1; Insulation asbestos mats 5 to avoid direct contact. In addition, a positioning base 6 with a positioning hole is provided to be sleeved on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com