Device and method for testing cavitation characteristics of materials in polymer solution

A polymer solution and measuring device technology, applied in the direction of testing wear resistance, etc., can solve problems affecting test stability and accuracy, viscosity reduction, etc., achieve high accuracy, eliminate the impact of degradation, and ensure solution viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

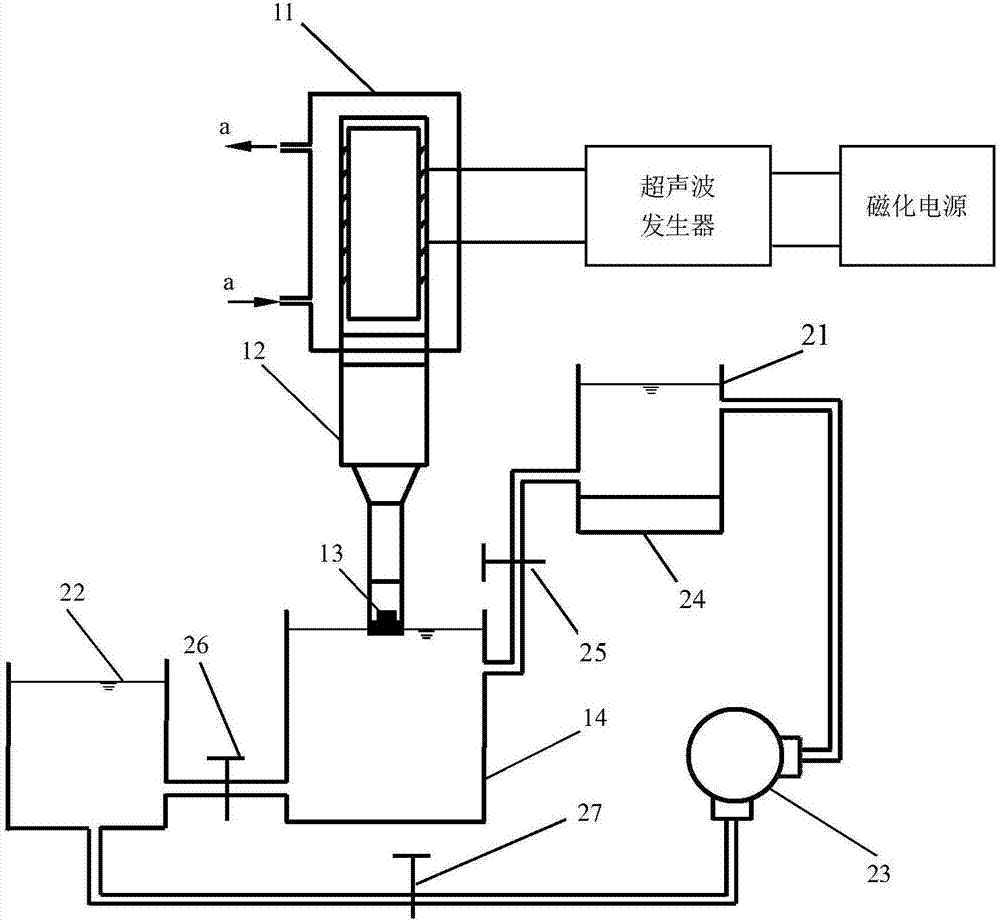

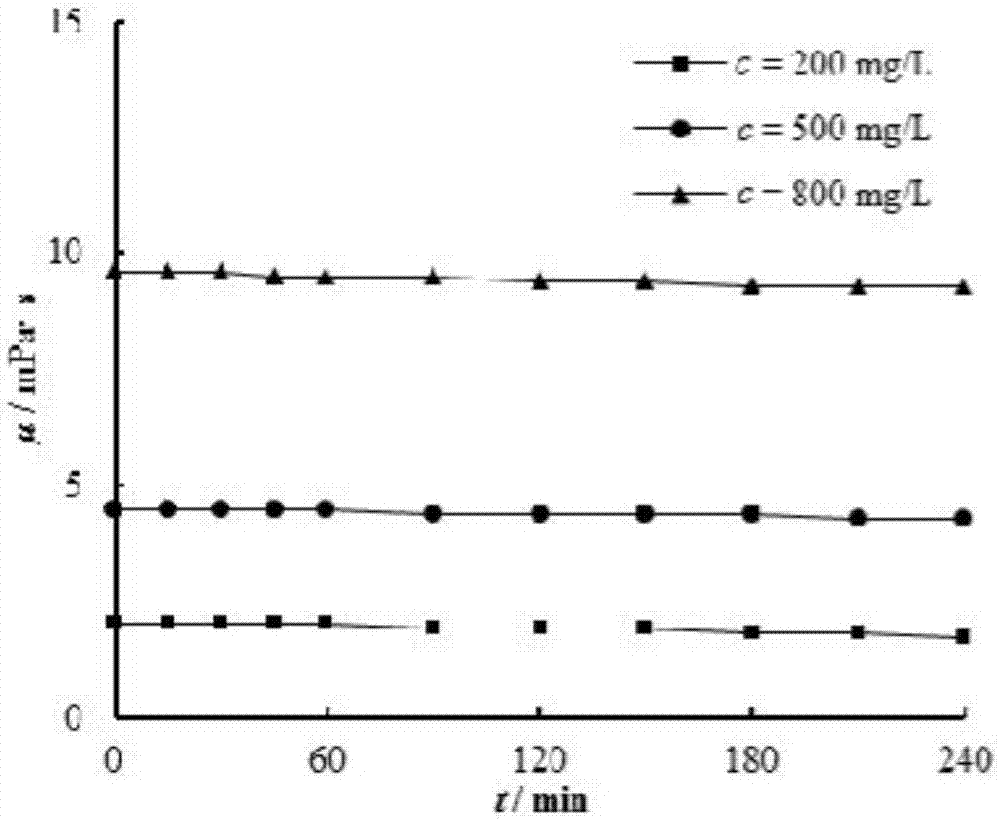

[0027] A measuring device for cavitation characteristics of materials in a polymer solution, comprising a magnetostrictive oscillator and a test tank 14 equipped with a polymer solution test solution, and a test piece is arranged on the horn 12 of the magnetostrictive oscillator 13. A test liquid circulation system is connected to the test tank 14. The test liquid circulation system includes a liquid supply tank 21, a liquid collection tank 22 and a diaphragm pump 23. The inlet and outlet of the diaphragm pump 23 are respectively connected to the liquid supply tank 21 and the collection tank. The liquid tank 22 is connected, and is used to make the polymer solution in a circulating flow state during the measurement of the cavitation characteristics of the material, so as to ensure that the viscosity of the polymer solution is stable, so that the measurement results of the cavitation characteristics of the material are stable and accurate, and the supply The height of the liquid...

Embodiment 2

[0030] A method for determining the cavitation properties of materials in polymer solutions,

[0031] Step 1 Clean and dry the test piece, cool it to room temperature, weigh and record the weight of the cooled test piece, then install the test piece at the end of the horn of the magnetostrictive oscillator, and place the test piece in the test tank Inside,

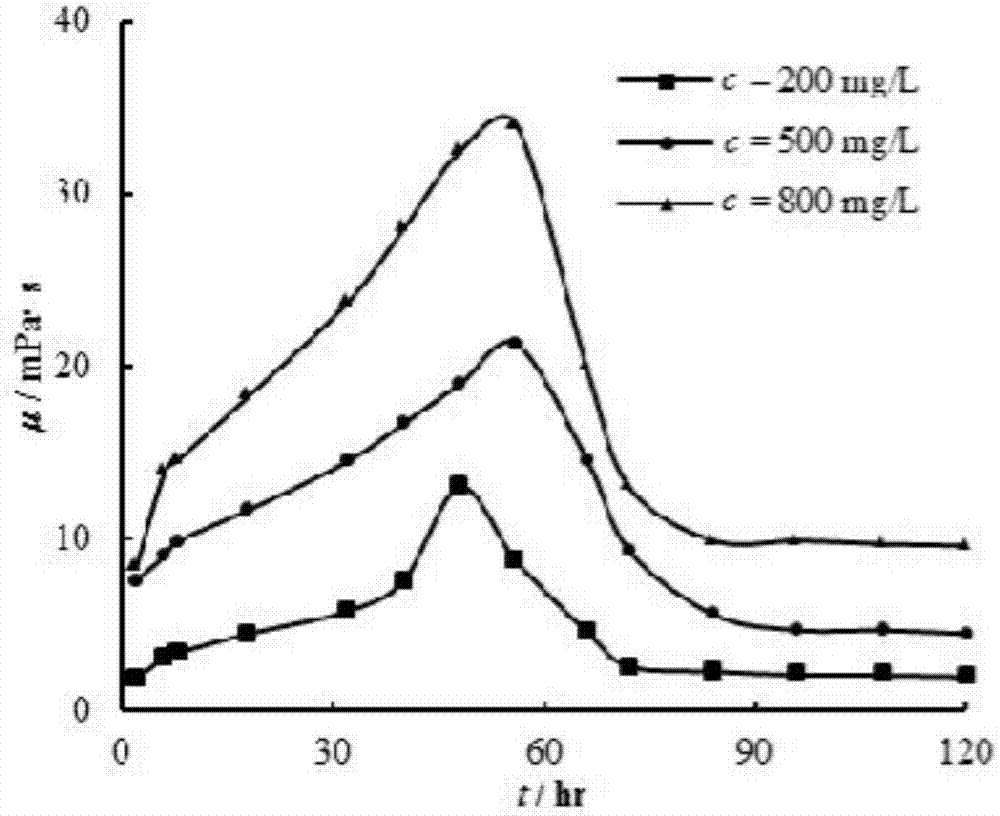

[0032] Step 2. Let the polymer solution stand still so that it enters the stable period of viscosity and record the viscosity and initial concentration of the polymer solution, then pour the polymer solution into the test tank, immerse the test piece in the polymer solution for 2-5mm, and Select at least 3 temperature values between the freezing point and the boiling point of the polymer solution as the temperature set in the experiment, and at the same time maintain the temperature of the polymer solution at the temperature set in the experiment selected, and polymerize at the set temperature selected in the experiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com