High-heat-absorption fixing roller for high-speed engineering duplicating machine and manufacturing method of high-heat-absorption fixing roller

A manufacturing method and technology of copiers, applied in the fields of electric recording process using charge pattern, equipment for electric recording process using charge pattern, and electrography, etc., capable of solving problems such as poor fixation, absorption of high-power heating lamp tubes, fixing rollers Problems such as small inner diameter can solve the problem of weak fixation, problem of continuous copying, and improvement of absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

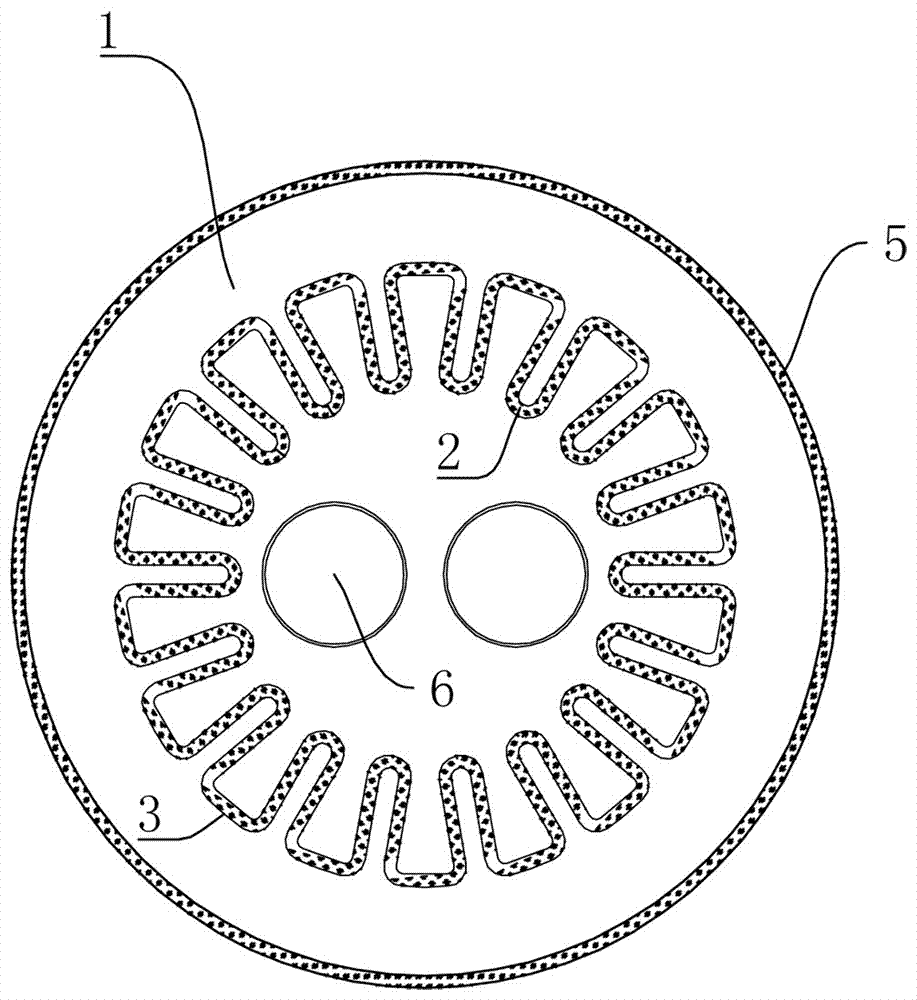

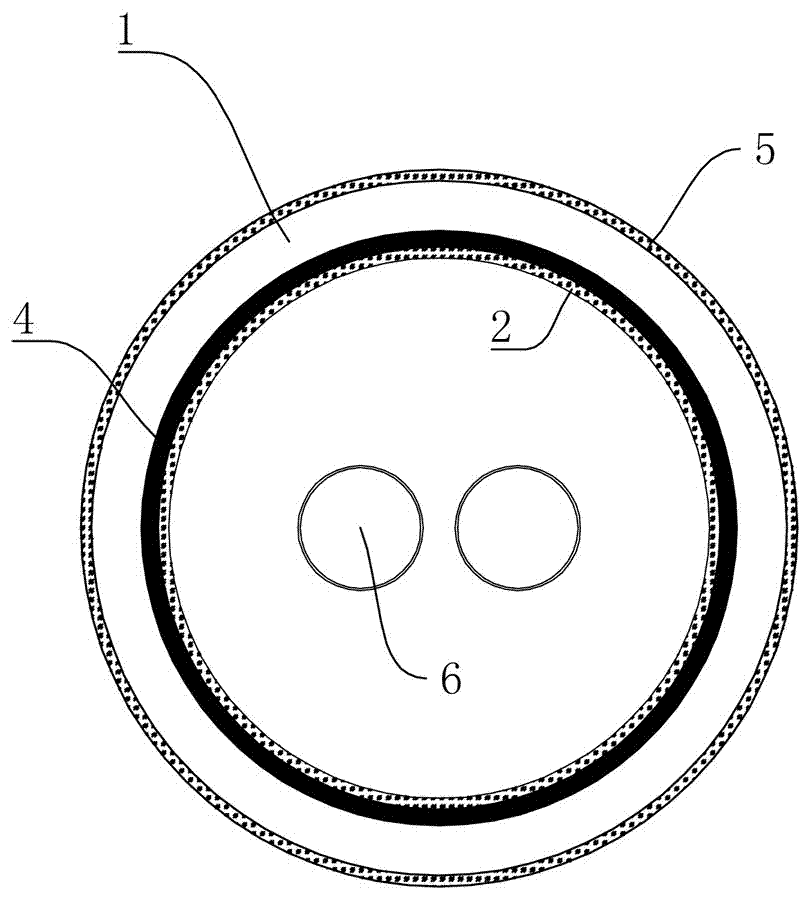

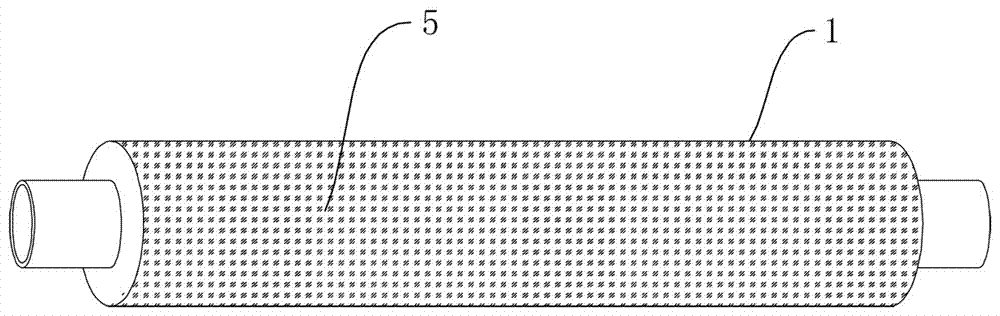

[0032] Such as figure 1 or figure 2 As shown, this high-speed engineering copier high heat-absorbing fixing roller includes a tubular roller body 1, the inner surface of the roller body 1 is sprayed with a far-infrared heat-absorbing coating 2, and the far-infrared heat-absorbing coating 2 can improve the high-power lamp. The heat absorption rate of the tube, the lamp tube heats up, and the roller body 1 absorbs it, and then transfers the heat to the roller surface in time to ensure that the temperature of the roller body 1 is uniform, effectively solving the problems of weak copy fixation and continuous copying, and this The high heat-absorbing fixing roller of high-speed engineering copier is easy to manufacture and can be reused without adding gas; the far-infrared heat-absorbing coating 2 in this technical solution can be ZS-1061 far-infrared heat-absorbing coating, specifically, the far-infrared heat-absorbing coating 2 The heat-absorbing coating is processed by mixing ...

Embodiment 2

[0034] Such as figure 1 Shown is a cross-sectional view of this embodiment. On the basis of Embodiment 1, this embodiment extends the inner wall of the roller body 1 radially outward to form several concave portions 3 evenly distributed along the circumferential direction, and all the concave portions The parts 3 extend along the length direction of the roller body 1, and the inner wall contour is petal-shaped from the cross-sectional view. Through this technical solution, the heat-receiving area of the inner diameter of the roller body 1 can be increased, and the heat-absorbing area of the inner wall of the roller body 1 is increased by 2 -4 times (the specific heat absorption area can be adjusted according to actual needs), so the heat absorption area is enough to absorb the heat emitted by the high-power heating lamp 6, and the heat will not spread to both ends due to insufficient heat absorption. Heat generation, the roller body 1 absorbs heat in time, so that the temp...

Embodiment 3

[0036] Such as figure 2 Shown is the cross-sectional view of this embodiment. On the basis of Embodiment 1, this embodiment adds a high thermal conductivity red copper tube 4 on the inner wall of the roller body 1. By utilizing the high thermal conductivity of red copper, the heat absorption rate of red copper is greater than that of The heat emitted by the high-power heating lamp tube 6 will not spread to both ends due to insufficient heat absorption. The high-power lamp tube generates heat on one side, and the roller body 1 absorbs heat in time, so that the entire surface temperature of the roller body 1 is uniform, which further solves the problem of copying. The fixing of the document is not firm and the problem of continuous copying cannot be solved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com