Plane moulding bed graph automatic generation system and method

An automatic generation and tire frame technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of complicated calculation of tire frame data, error-prone tire frame diagrams, and poor drawing quality, so as to avoid out-of-the-box problems. The effect of low drawing efficiency, improving drawing quality and efficiency, and reducing design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

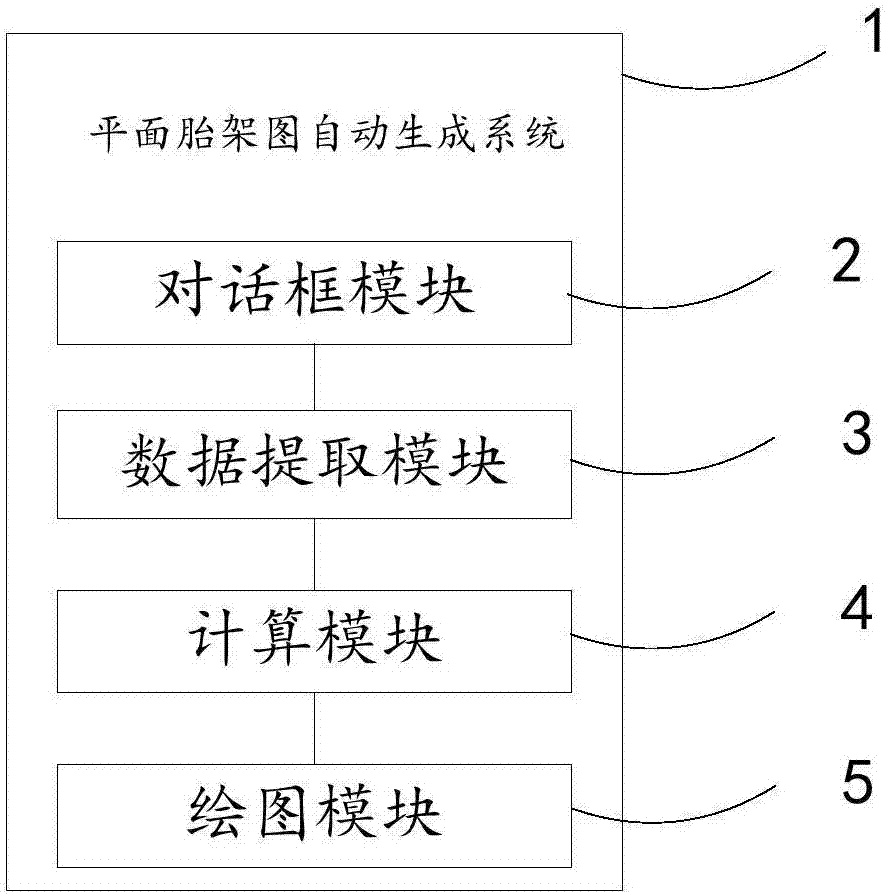

[0062] Such as figure 1 As shown, the present embodiment provides a system 1 for automatically generating a planar tire frame diagram, including:

[0063] Dialog module 2, used to obtain the tire plate parts list and tire frame parameters;

[0064] The data extraction module 3 is used to extract the tire plate part data from the ship design system database;

[0065] Calculation module 4, used to obtain the pillar coordinates according to the tire frame parameters and the tire plate part data; further used to obtain the pillar height according to the pillar coordinates, tire plate part data and pillar height reference;

[0066] The drawing module 5 is used for drawing tire frame diagrams according to the data of the pillar coordinates and the height of the pillars.

[0067]Specifically, the tire-mounting board parts table is a list of board parts names selected by the user for drawing tire frame diagrams; the tire frame parameters include X-axis reference line, Y-axis referen...

Embodiment 2

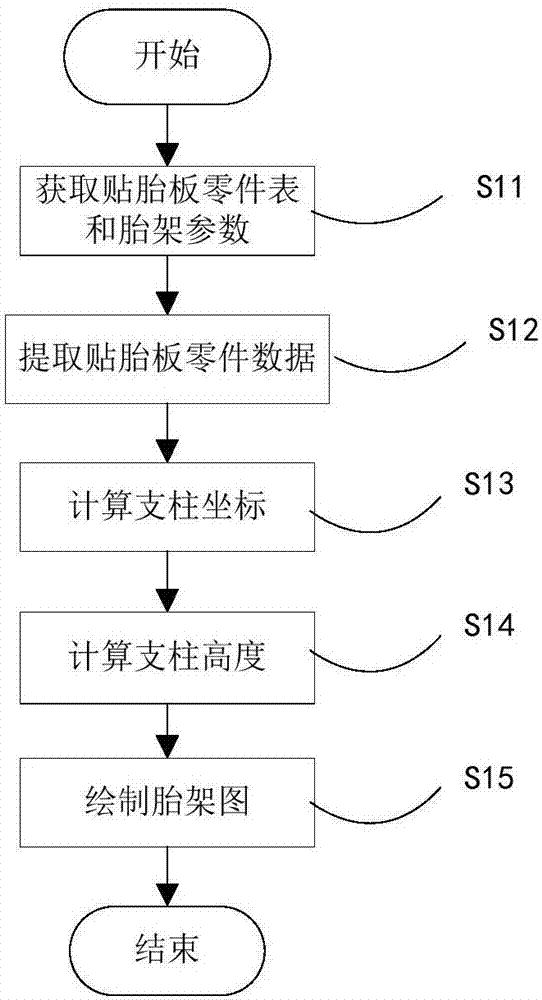

[0069] This embodiment provides a method for generating a planar frame diagram using the system in Embodiment 1, such as figure 2 As shown, it is a flow chart of a preferred embodiment of the method for automatically generating a planar frame diagram of the present invention. Specifically, the method includes:

[0070] Step S11, obtaining the tire plate parts selected by the user and the input tire frame parameters;

[0071] Step S12, extracting tire plate parts data;

[0072] Specifically, the data information of the tire-mounted parts is extracted in the ship design system database according to the tire-mounted parts table;

[0073] Step S13, calculating the pillar coordinates;

[0074] Specifically, the pillar coordinates are calculated according to the X-axis reference line, the Y-axis reference line, the pillar spacing, the maximum margin value, the edge indent value and the tire-mounted part data;

[0075] Step S14, calculating the height of the pillar;

[0076] Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com