A kind of preparation method of ultra-thin lithium strip for lithium metal battery

A technology for lithium metal batteries and lithium strips, applied in battery electrodes, secondary batteries, electrode manufacturing, etc., can solve the problems of difficult to control thickness, inability to realize ultra-thin lithium sheet preparation, and large mold reaction loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

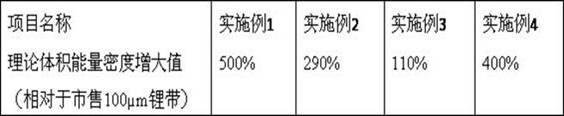

Embodiment 1

[0015] Install the 10 micron thick copper foil on the winding machine through the casting roll and the calendering roll, and then control the humidity of the heating kettle and the casting and calendering working chamber below 1%, and the vacuum degree is -0.1MPa, and heat the heating kettle to 180°C, put the lithium ingot into the heating kettle through the transition chamber, open the feeding port after the lithium ingot melts, and use argon to pressurize the heating kettle (5 MPa), so that the molten lithium flows evenly through the casting die. Extended on the copper foil, the die head gap is 200 microns, the winding speed of the copper foil is controlled at 10 m / min, after the cooling roll, the temperature of the composite lithium strip is at 100°C, and the gap of the two-roll calender is adjusted at 20 microns, the lithium strip passes through the gap, and the total thickness is 20 microns after secondary rolling, and the effective thickness of the lithium strip is 10 mic...

Embodiment 2

[0017] Install the 12-micron thick copper foil on the winding machine through the casting roller and calendering roller, then control the humidity of the heating kettle and the casting and calendering working chamber below 1%, and the vacuum degree is above -0.1MPa, and heat the heating kettle to 180°C, put the lithium ingot into the heating kettle through the transition chamber, open the feeding port after the lithium ingot melts, and use argon to pressurize the heating kettle (5 MPa), so that the molten lithium passes through the casting die evenly Flow cast on the copper foil, the die gap is 200 microns, the coiling line speed of the control copper foil is at 10 m / min, after passing through the cooling roll, the temperature of the composite lithium strip is controlled at 100°C, and the temperature of the double-roll calender is adjusted. The gap is 30 microns, the lithium strip passes through the gap, and the total thickness is 30 microns after secondary rolling. The effect...

Embodiment 3

[0019] Install the 40-micron thick laser perforated copper foil on the winding machine through the casting roll and the calendering roll, and then control the humidity of the heating kettle and the casting and calendering working chamber to be below 1%, and the vacuum degree to be above -0.1MPa. Heat the heating kettle to 200°C, add lithium ingots into the heating kettle through the transition chamber, open the feeding port after the lithium ingots are melted, and use argon to pressurize the heating kettle (6MPa), so that the molten lithium passes through the casting die The head is evenly cast onto the copper foil, the gap between the die heads is 300 microns, the winding speed of the copper foil is controlled at 12 m / min, and the temperature of the composite lithium strip is controlled at 100 ° C after passing through the cooling roll, and the double-roller calendering is adjusted The gap of the machine is 90 microns, the lithium strip passes through the gap, and the total th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com