Gripping manipulator

A technology of grasping manipulators and driving mechanisms, applied in manipulators, chucks, manufacturing tools, etc., can solve problems such as speed loss and unstable operation speed, and achieve the effect of reducing speed loss, simple structure, and good motion neutrality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

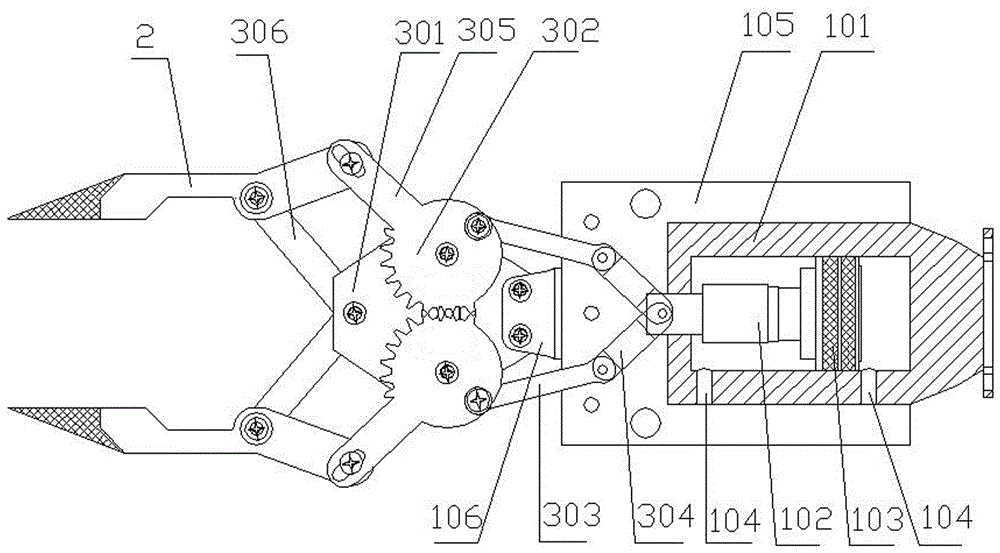

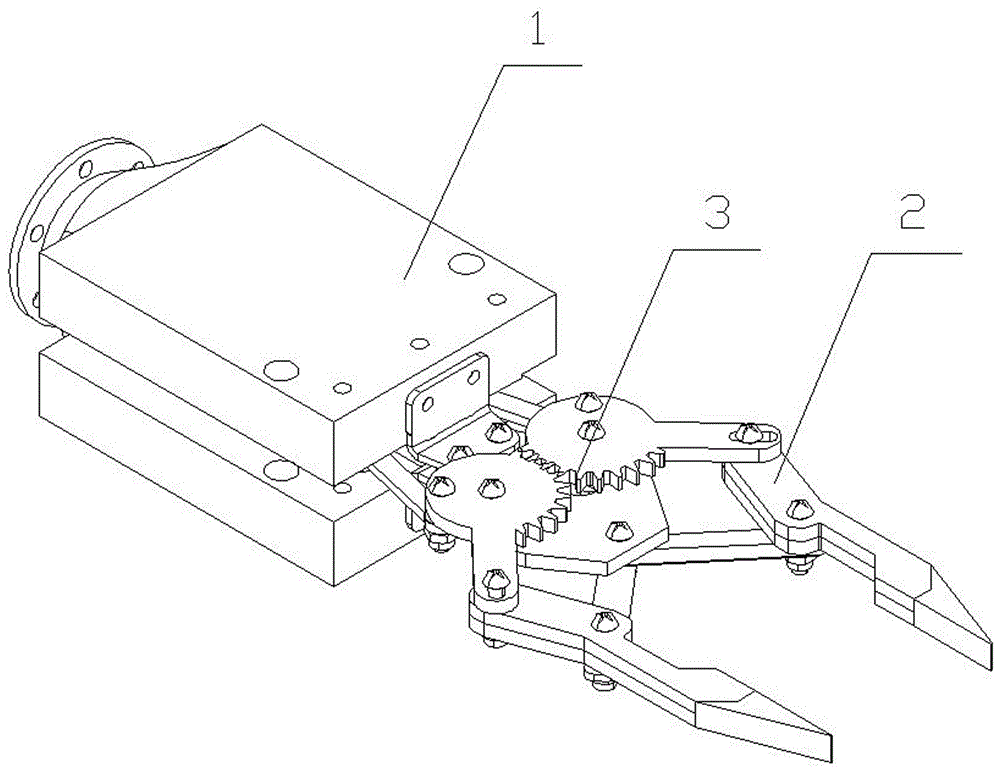

[0018] Such as figure 1 and figure 2 As shown, a grabbing manipulator of the present invention includes a driving mechanism 1, two claws 2 and a device for connecting the driving mechanism 1 and the two claws 2 and controlling the two claws according to the output of the driving mechanism 1 2 Complete torque transmission mechanism 3 for clamping or loosening. The driving mechanism 1 is a linear cylinder, the driving medium is compressed air, and the torque transmission mechanism 3 is mechanical, which not only has low manufacturing cost, but also has a stable structure and a long service life.

[0019] The driving mechanism 1 includes a cylinder body 101 with a shaft hole at one end and a piston rod 102 with a shaft diameter corresponding to the shaft hole. The piston rod 102 is slidably arranged in the shaft hole through a dynamic seal, one end of which is arranged in the inner chamber of the cylinder body 101 , and the other end extends out of the inner chamber of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com