Hot pressing plate for non-woven fabric hot pressing device

A technology of hot pressing device and hot pressing plate, which is applied in the direction of textile and paper making, heating/cooling fabric, fabric surface trimming, etc. It can solve problems such as deformation of the hot pressing layer, and achieve the effects of avoiding impact, good heat conduction, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

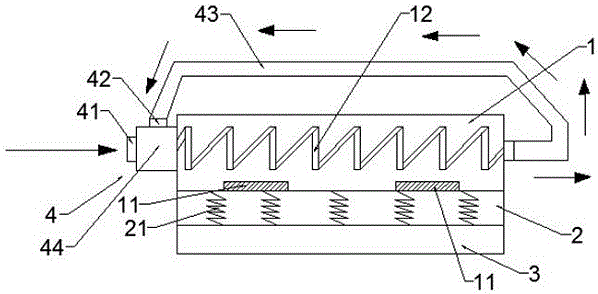

[0012] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0013] as attached figure 1 Shown, a kind of hot-pressing plate for non-woven fabric hot-pressing device comprises heating layer 1, buffer layer 2, hot-pressing layer 3, hot air blower 4; Said heating layer 1 is arranged on the top of said buffer layer 2, said The hot pressing layer 3 is arranged at the bottom of the buffer layer 2, and the hot air blower 4 is arranged at one end of the heating layer 1;

[0014] The hot air blower 4 includes a body 44, a first air inlet 41, a second air inlet 42, and a recovery pipe 43; the top of the body 44 is provided with the second air inlet 42, and the body 44 is far away from the heating layer. One side of 1 is provided with the first air inlet 41, and the recovery duct 43 is arranged above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com