Integrated manufacture method of perlite thermal insulation decoration for wall

A production method and technology of perlite, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of large load-bearing load, poor building thermal insulation performance, and labor consumption, etc. The effect of nailing and other processes, good sound insulation and heat preservation performance, saving process and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

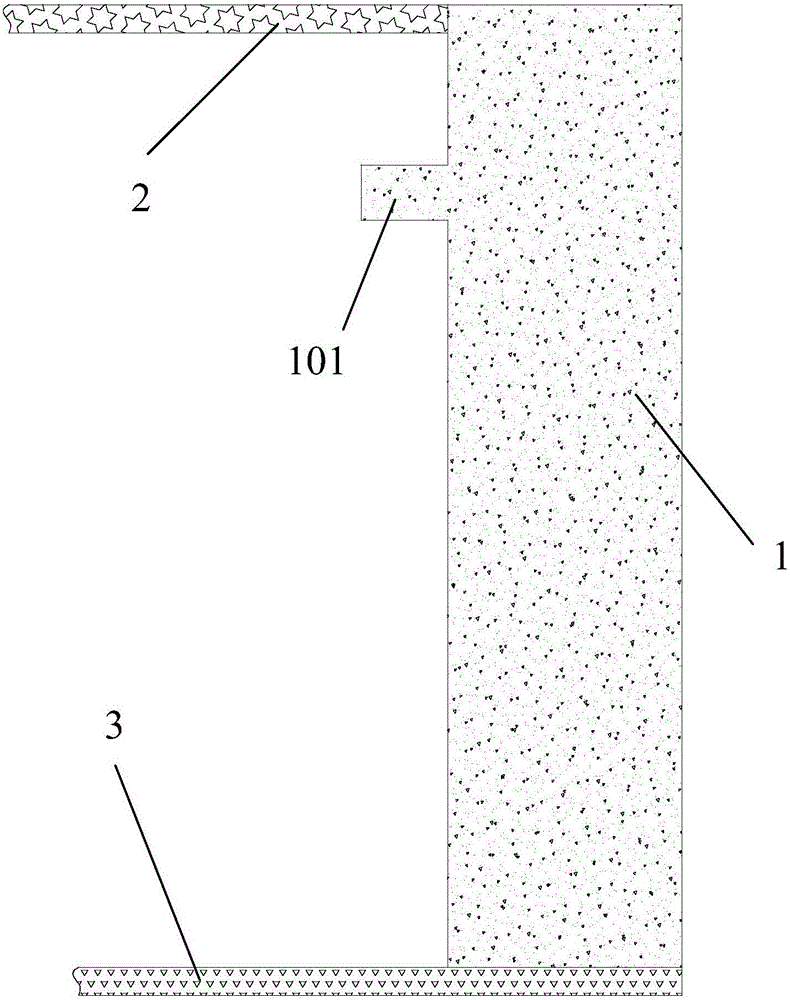

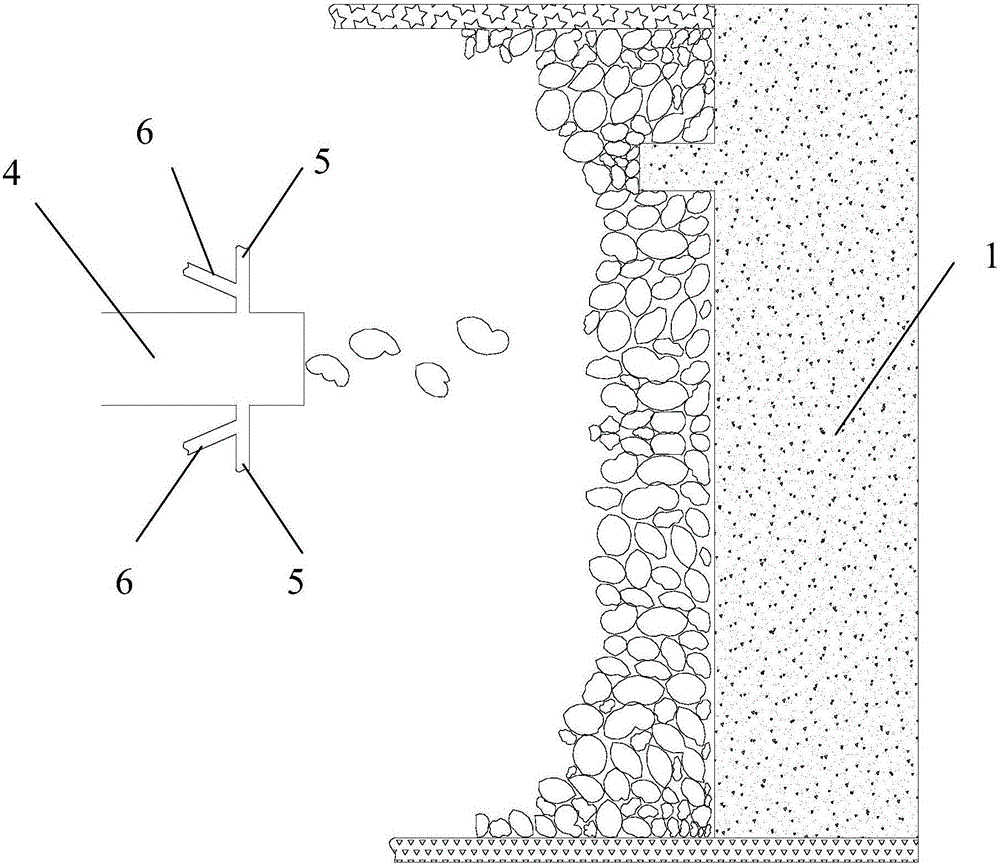

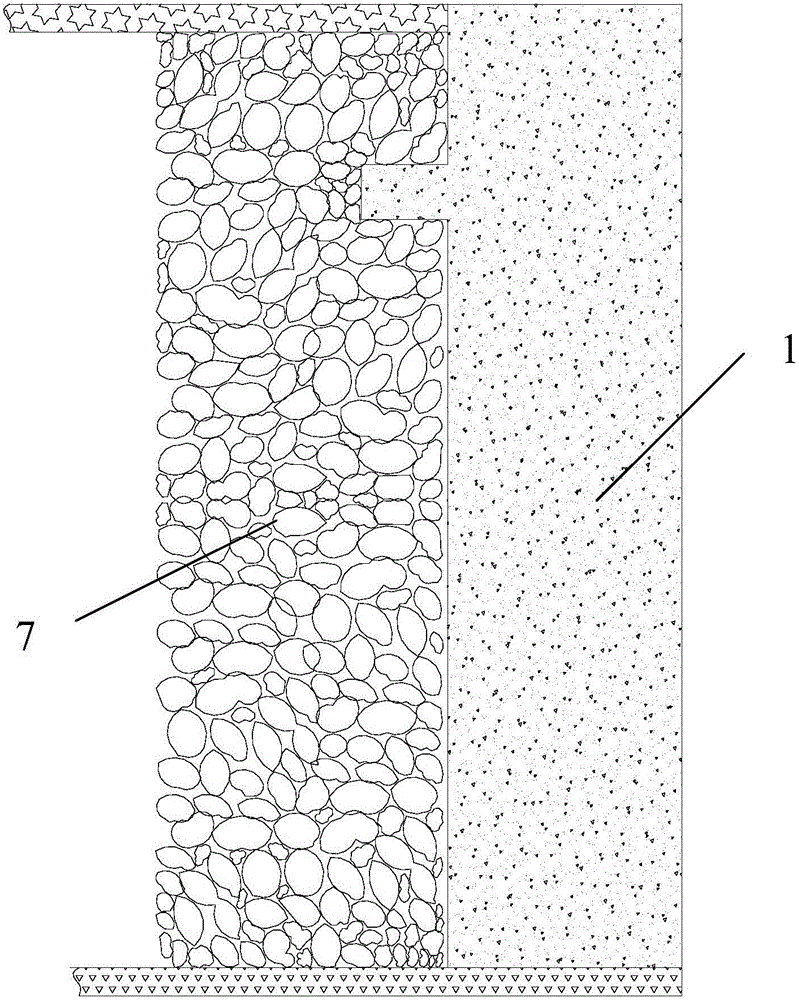

[0027] The invention provides a manufacturing method for significantly improving the thermal insulation performance and simultaneously completing the integration of surface decoration, and completing the integration of surface decoration while thermal insulation is carried out for building walls. Before starting the production, the wall can be treated first, figure 1 It is a schematic diagram of a wall without insulation and decoration, such as figure 1 As shown, the wall 1 is sandwiched between the ceiling 2 and the floor 3, and one side surface of the wall 1 is provided with a transverse convex strip 101 protruding from the wall. The transverse ribs 101 can improve the deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com