Vacuum preloading and piling preloading combined settling column tester and test method thereof

A technology of stacking preloading and settling columns, which is applied in the directions of instruments, measuring devices, surveying and mapping and navigation, etc., to achieve the effect of simple structure, reduced errors and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

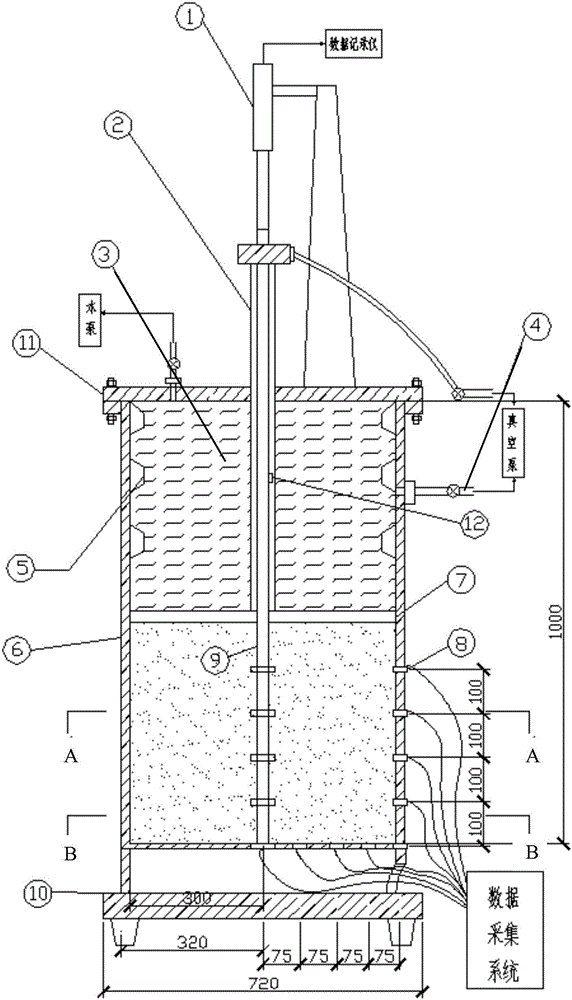

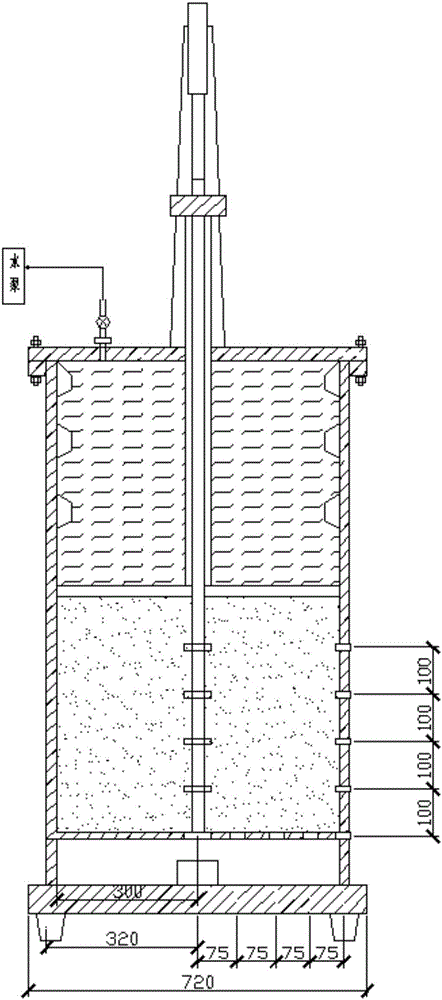

[0051] Below in conjunction with the example, the method for improving the settlement column test of dredging fill is described in detail. For the convenience of explanation, the schematic diagram showing the structure of the device will not be partially enlarged according to the general scale, and should not be used as a limitation of the present invention. In addition, in actual production In , the three-dimensional space dimensions of length, width and height should be included.

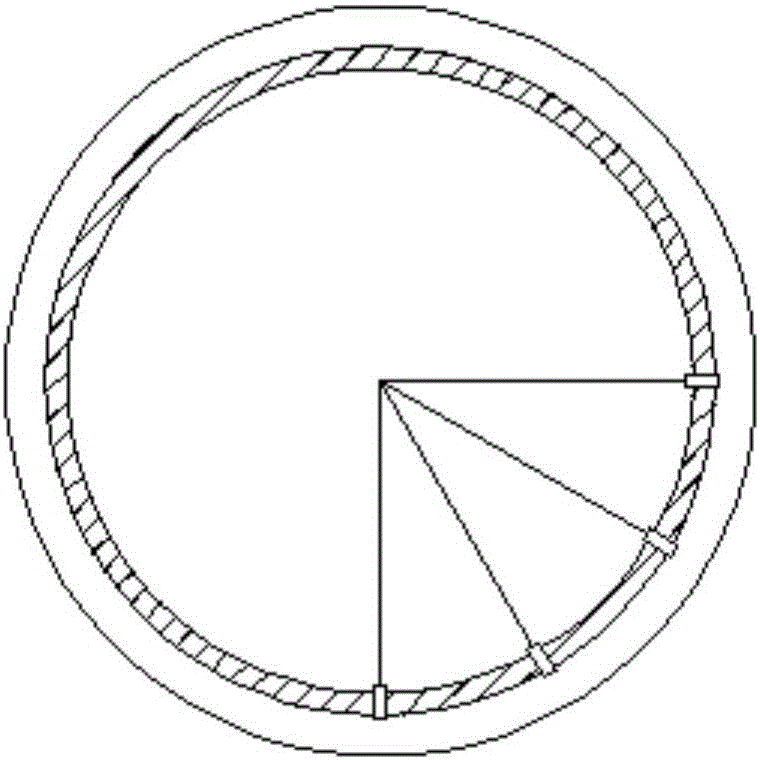

[0052] The settling column 6 is a cylindrical glass container with an open top and a closed bottom, with an inner diameter of 60 cm and a side wall thickness of 1 cm; 16 holes are arranged on four radii at intervals of 30° at the bottom of the settling column 6, and the side walls are provided with 4 rows of each There are 4 rows of 4×4=16 hole slots in total, wherein the height spacing of each row of hole slots is 12.5 cm, and these hole slots are used for installing hole pressure sensors 8 . In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com