Processing process of pungent and spicy beef jerky

A processing technology, beef jerky technology, applied in the field of spicy beef jerky processing technology, can solve the problems of beef jerky losing its tenderness, limited frying time, and difficulty in chewing, so as to avoid edible oil from becoming bitter and meat from aging , the effect of increasing the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

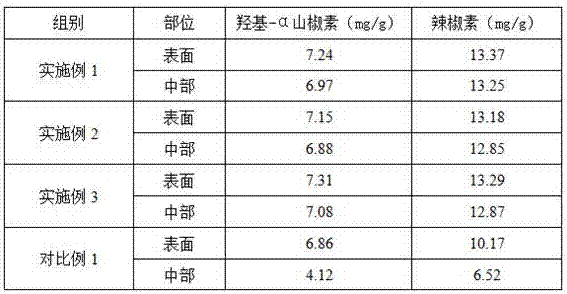

Examples

Embodiment 1

[0022] Embodiment 1: a kind of processing technology of spicy beef jerky, comprises the following steps:

[0023] Step 1. Prepare 10kg of beef, 6 kg of edible vegetable oil, 2 kg of peppercorns, 0.5 kg of salt, 3 kg of potatoes, and 2 kg of millet pepper. Cut the millet pepper into sections, add salt and mix well; add water to the potatoes and crush them into a slurry to obtain potato slurry;

[0024] Step 2: Put the edible vegetable oil into a frying pan and heat to boil, then add peppercorns, fry at 110-120°C for 20-30 minutes, then stop heating, and cool to room temperature with oil;

[0025] Step 3. Wash and soak the beef to remove blood, then cut into slices, cubes or strips with a thickness of 1-1.5cm. Put the cut beef into the potato slurry and mix well so that potatoes are hung on the surface of the beef For the slurry, seal it with plastic wrap, refrigerate it at 3-8°C for 3-5 hours, take it out and let it return to room temperature naturally, then brush off the pota...

Embodiment 2

[0027] Embodiment 2: a kind of processing technology of spicy beef jerky, comprises the following steps:

[0028] Step 1. Prepare 8 kg of beef, 8 kg of edible vegetable oil, 3 kg of peppercorns, 0.4 kg of salt, 1 kg of potatoes, and 2 kg of millet pepper. Cut the millet pepper into sections, add salt and mix well; add water to the potatoes, and crush them into Slurry obtains potato slurry;

[0029] Step 2: Put the edible vegetable oil into a frying pan and heat to boil, then add peppercorns, fry at 110-120°C for 20-30 minutes, then stop heating, and cool to room temperature with oil;

[0030] Step 3. Wash and soak the beef to remove blood, then cut into slices, cubes or strips with a thickness of 1-1.5cm. Put the cut beef into the potato slurry and mix well so that potatoes are hung on the surface of the beef For the slurry, seal it with plastic wrap, refrigerate it at 3-8°C for 3-5 hours, take it out and let it return to room temperature naturally, then brush off the potato ...

Embodiment 3

[0032] Embodiment 3: a kind of processing technology of spicy beef jerky, comprises the following steps:

[0033] Step 1. Prepare 9 kg of beef, 7 kg of edible vegetable oil, 2 kg of peppercorns, 0.6 kg of salt, 2 kg of potatoes, and 3 kg of millet pepper. Cut the millet pepper into sections, add salt and mix well; add water to the potatoes, and crush them into Slurry obtains potato slurry;

[0034] Step 2: Put the edible vegetable oil into a frying pan and heat to boil, then add peppercorns, fry at 110-120°C for 20-30 minutes, then stop heating, and cool to room temperature with oil;

[0035] Step 3. Wash and soak the beef to remove blood, then cut into slices, cubes or strips with a thickness of 1-1.5cm. Put the cut beef into the potato slurry and mix well so that potatoes are hung on the surface of the beef For the slurry, seal it with plastic wrap, refrigerate it at 3-8°C for 3-5 hours, take it out and let it return to room temperature naturally, then brush off the potato ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com