Waste gas treatment device in food packaging bag production

A technology of waste gas treatment device and packaging bag, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of short contact time between waste gas and circulating liquid, achieve good absorption and purification effect, increase residence time, The effect of more contact time

Inactive Publication Date: 2017-12-08

广德美好包装科技股份有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the above-mentioned technical problems, the present invention provides a waste gas treatment device in the production of food packaging bags to solve the problem of short contact time between waste gas and circulating liquid in the current spray equipment for treating waste gas

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

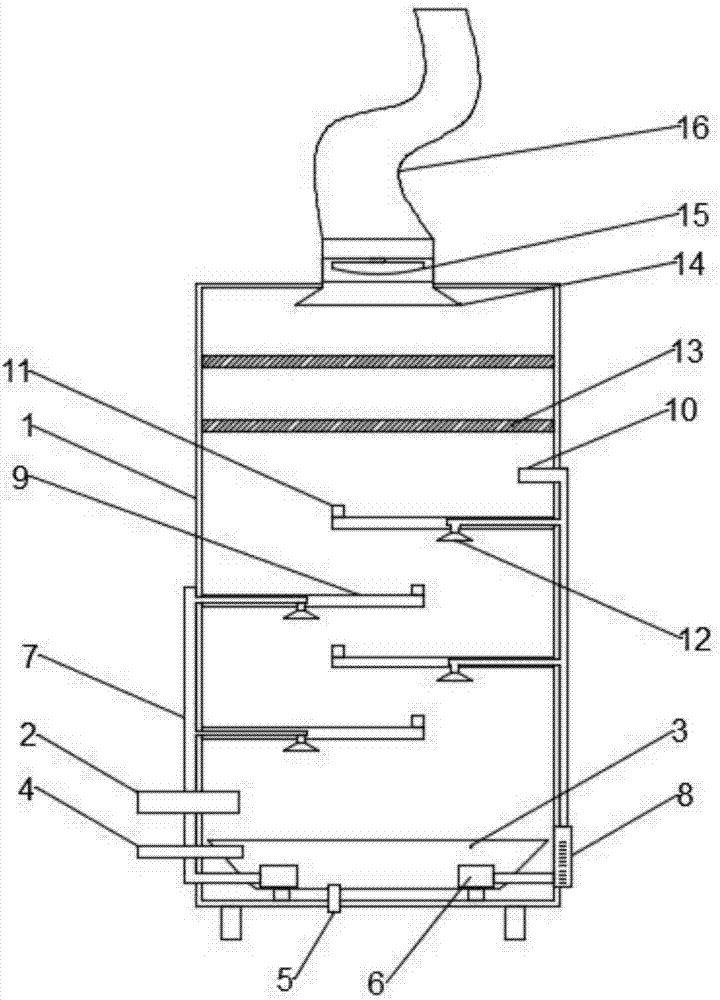

The invention discloses a waste gas treatment device in food packaging bag production in the technical field of processing of packaging bags. The waste gas treatment device comprises a spray tower, wherein the interior of the spray tower sequentially comprises a circulating chamber, a spray chamber and an adsorption chamber from bottom to top; the circulating chamber comprises an air inlet and a circulating pool; a plurality of horizontally arranged baffles are arranged in the spray chamber; the plurality of baffles are arranged in the spray chamber in a cross manner, so that a 'Z' waste gas passage is formed in the spray chamber; discharge plates are connected to one ends of the baffles which are not connected with the spray tower; the baffles are connected with nozzles; an activated carbon adsorption layer and an air outlet are arranged in the adsorption chamber; the air outlet is positioned in the center on the top of the adsorption chamber; an exhaust fan is arranged in the air outlet. According to the waste gas treatment device disclosed by the invention, waste gases in the food packaging bag production can be effectively purified, the contact time of the waste gases and spray liquid is increased, and the absorption and purification effect is improved.

Description

technical field [0001] The invention relates to the technical field of packaging bag processing, in particular to a waste gas treatment device in the production of food packaging bags. Background technique [0002] With the rapid growth of the application of plastic food packaging bags and the rapid development of the economy, the production enterprises of flexible packaging bags are also increasing, but at the same time, the impact of various harmful gases on the atmospheric environment is becoming more and more prominent. In the discharge process, it pollutes the environment and consumes energy. [0003] The main raw material for plastic food packaging bags is polyethylene. When high-pressure polyethylene is heated to 150°C, it will decompose acids, esters, unsaturated hydrocarbons, peroxides, formaldehyde, acetaldehyde, CO2 and CO, etc.; its film products should be Pay attention to the toxicity hazards caused by antioxidants, stabilizers and colorants; low-pressure polye...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/18B01D53/04

CPCB01D53/0407B01D53/18

Inventor 张建平

Owner 广德美好包装科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com