Compound cavitation cleaner for pipe descaling and with two-grade resonance function

A composite cleaner technology, applied in chemical instruments and methods, cleaning hollow objects, cleaning methods and appliances, etc., can solve problems such as small shock waves, damage to personal health, corrosion of pipes, etc., and achieve instantaneous energy improvement, Improve the effect of cavitation and good vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

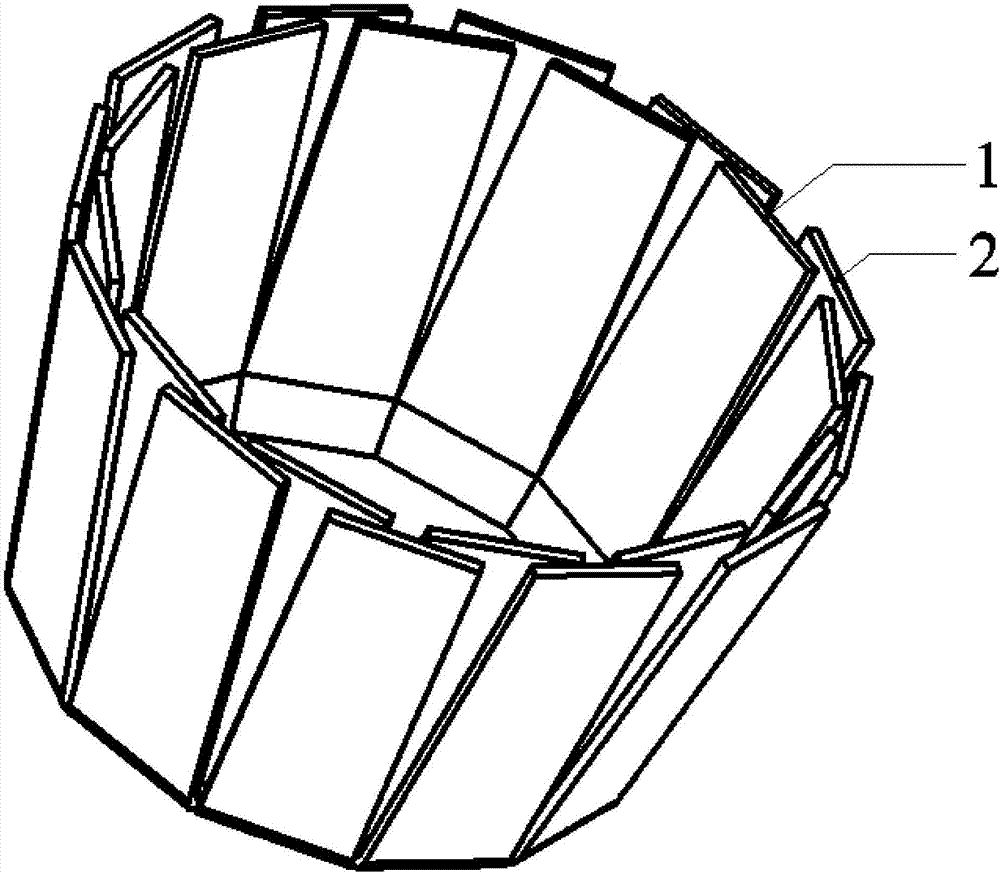

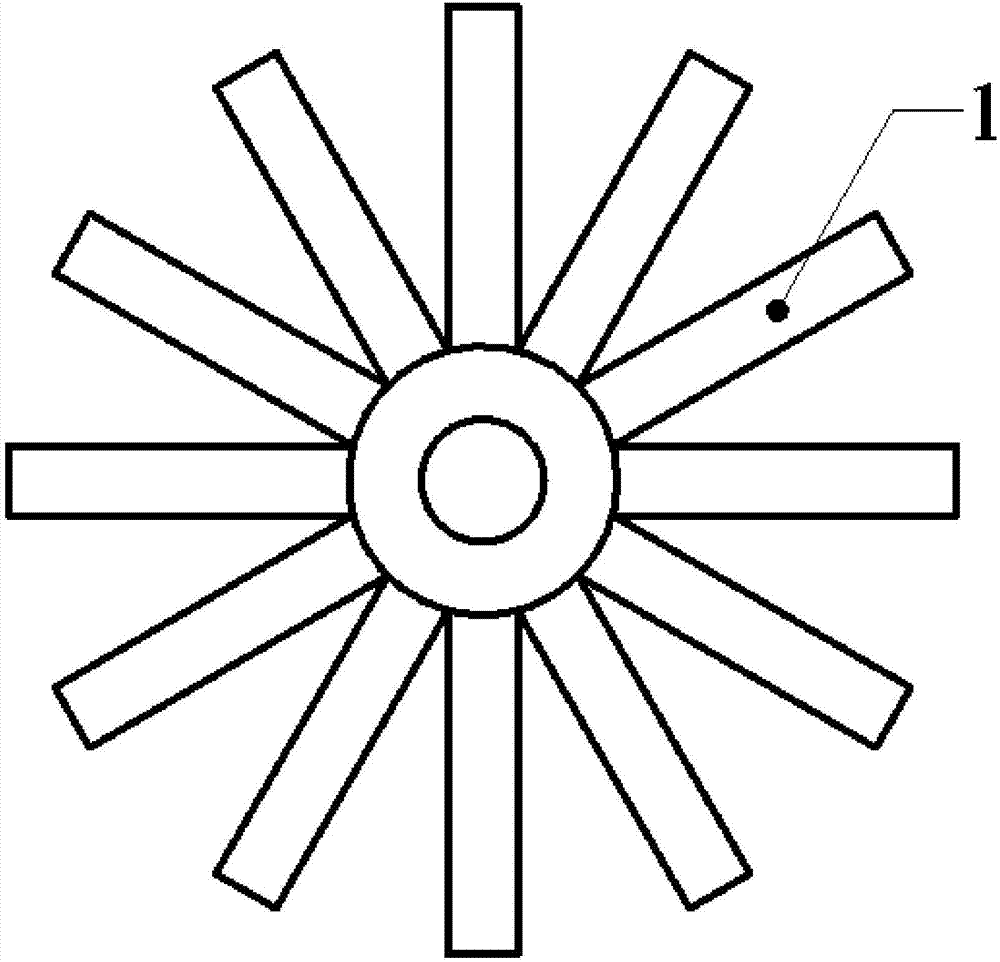

[0032] Such as Figure 1-6 As shown, the composite cavitation cleaner for pipeline descaling with two-stage resonance function includes a blade cleaning structure and a Helmholtz cavitation nozzle 3, and the blade cleaning structure and Helmholtz cavitation nozzle 3 connected as a whole through the upper self-locking nut 5 and the lower self-locking nut 8;

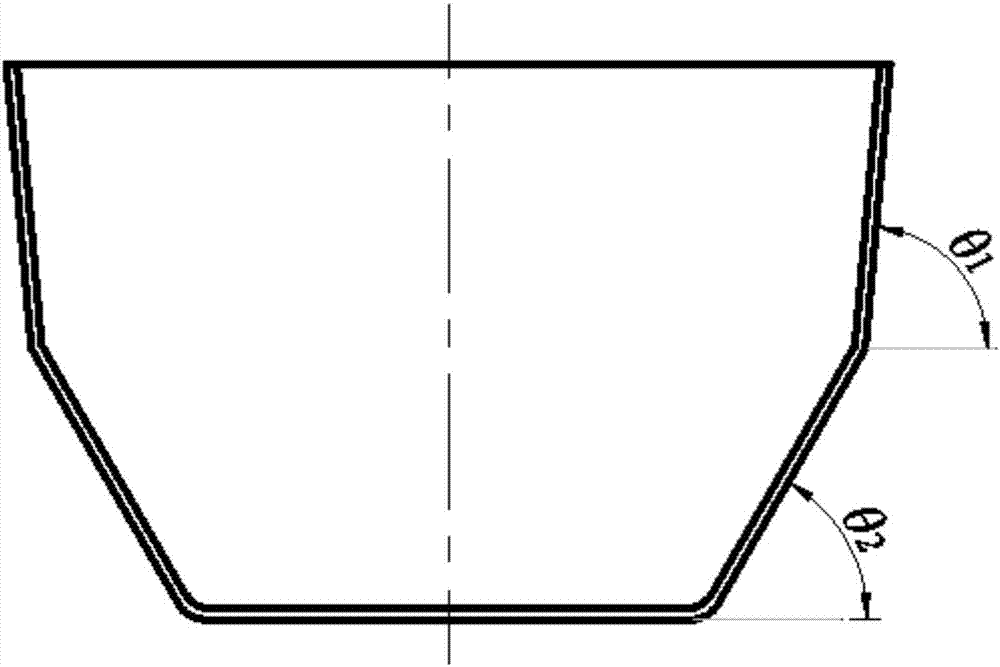

[0033] The blade cleaning structure includes two groups of inner blades 1 and outer blades 2, and the inner blades 1 and outer blades 2 are stacked together alternately; the blade cleaning structure is shaped by bending to have Bowl-shaped structure with double bending angle, and satisfying the bending angle θ 1 >θ 2 ;

[0034] The Helmholtz cavitation nozzle 3 is composed of an inlet cavity, an upper nozzle outlet, a resonance cavity and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com