Floating Die Punching Die for Car Roof

A technology of automobile top cover and die, applied in the direction of perforation tools, manufacturing tools, vehicle parts, etc., can solve the problems of difficult transformation, time-consuming redesign, processing and debugging of molds, and inability to transform, so as to reduce the risk of mold transformation, The effect of saving production preparation time and facilitating the installation of induction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

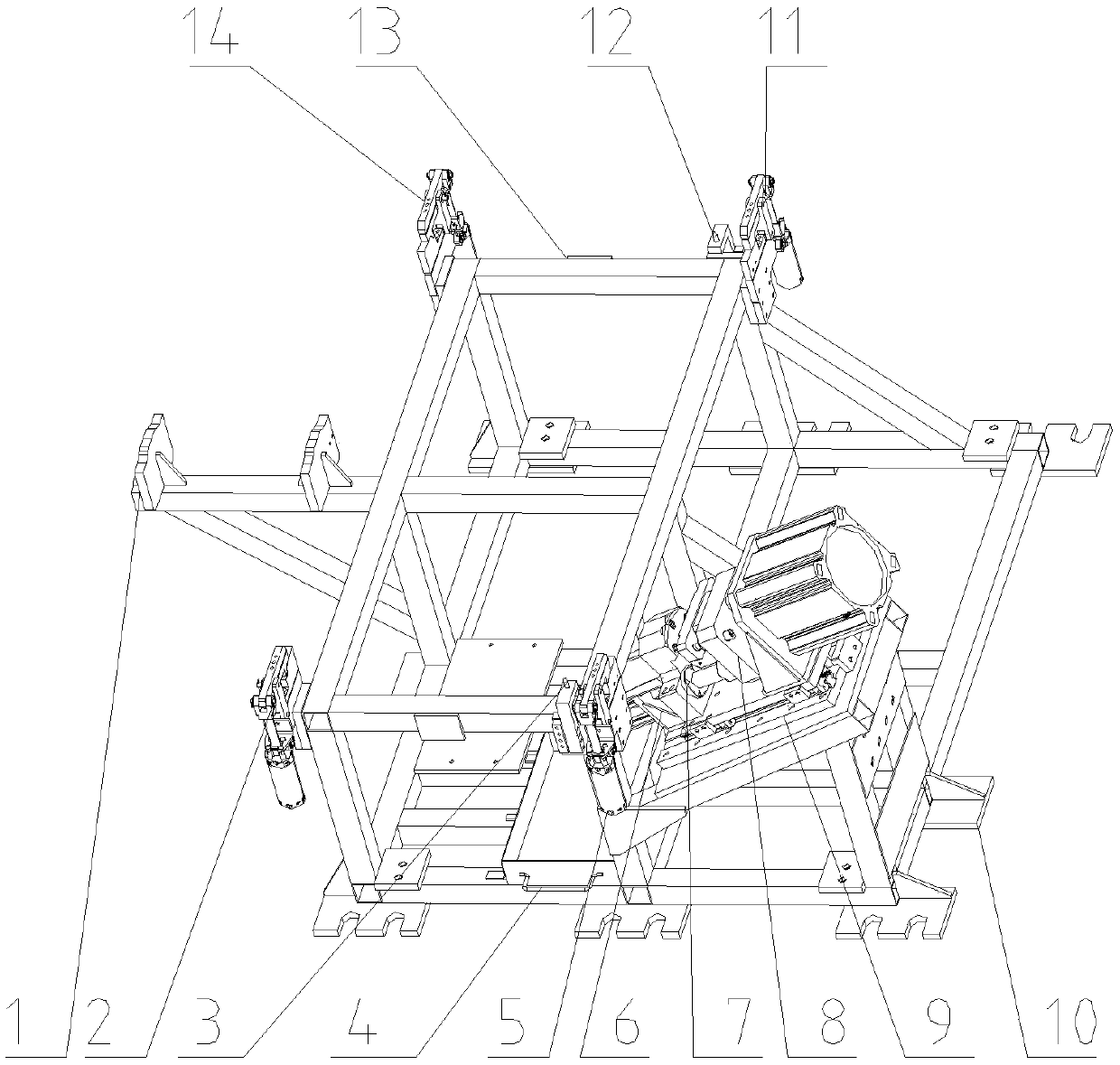

[0039] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the punching die of the floating die of the automobile roof includes a floating die assembly 7, a floating die drive assembly 6, a punching and stripping assembly 8, a roof positioning assembly 10 and a mold base 9, wherein the floating Die driving assembly 6 is connected with mold base 9, and mold base 9 is installed on top cover positioning assembly 10.

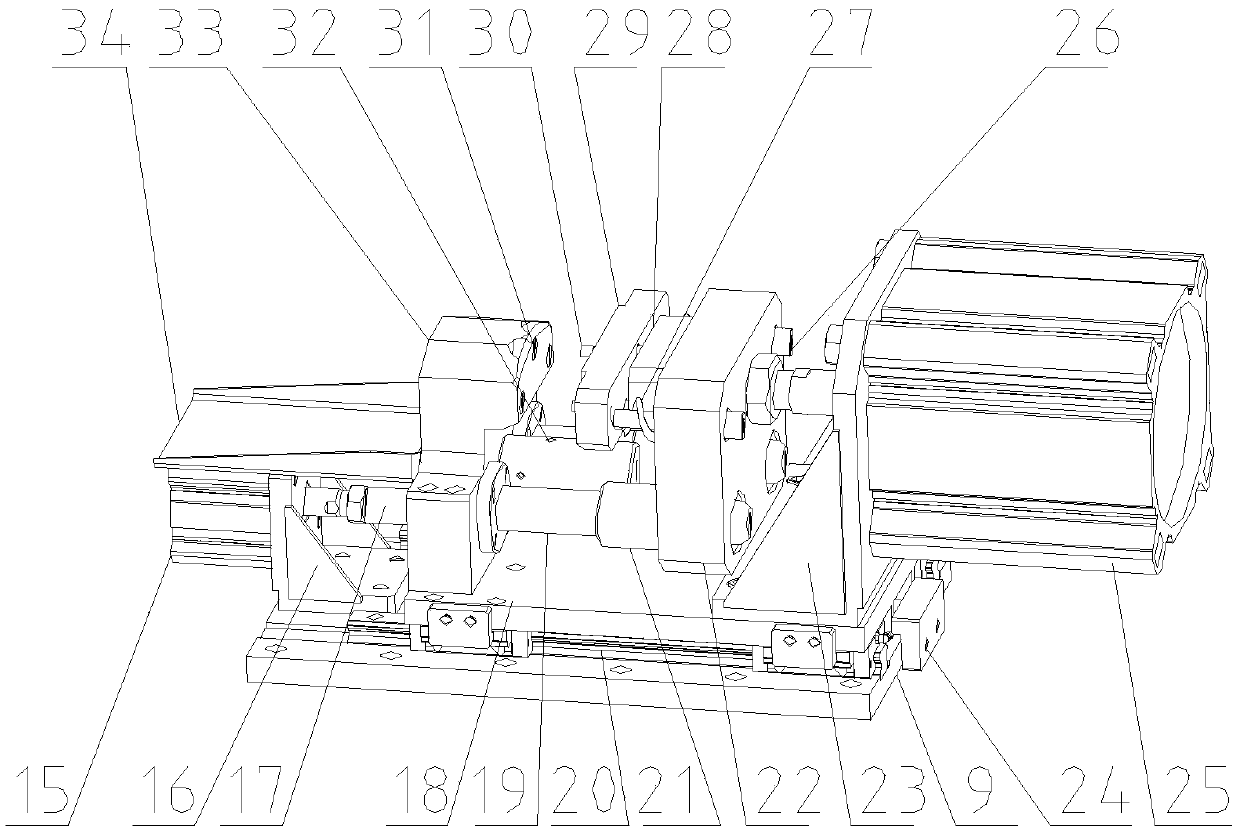

[0040] Floating die assembly 7 comprises die 31, die fixed block 33, guide column 19, limiter 32, waste material guide plate 34, carriage 18, linear guide rail 20 and carriage limit block 24, wherein die 31 installs On the die fixing block 33, a guide column 19, a stopper 32 and a waste guide plate 34 are also installed on the die fixing block 33, the die fixing block 33 is connected with the carriage 18, and the linear guide rail 20 is installed on the mold base 9 , the carriage 18 is installed on the linear guide rail 20 , and the carriage 18 moves ...

Embodiment 2

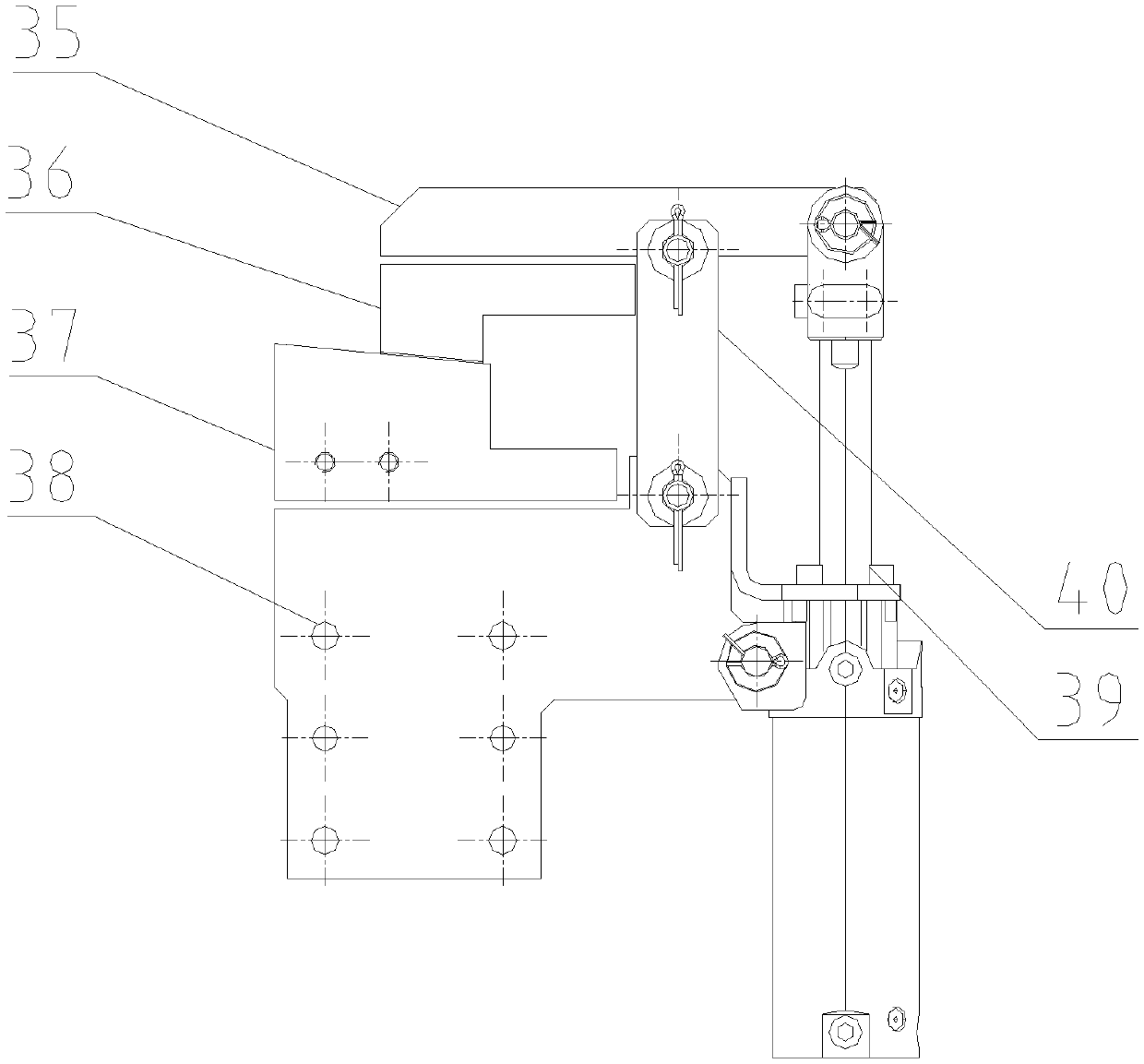

[0049] refer to figure 1 , figure 2 , image 3 and Figure 5 Embodiments of the present invention will be described. The working process of the punching die of the floating die of the automobile roof is the same as that of the first embodiment, except that the punching drive assembly 25, the die drive module 15 and the clamping cylinder 39 are controlled independently by three manual valves, while The three solenoid valves are in turn connected to the power source. The manual control valve 1 controls the punching drive assembly 25 , the manual control valve 2 controls the die drive module 15 , and the manual control valve 3 controls the clamping cylinder 39 .

Embodiment 3

[0051] refer to figure 1 , figure 2 , image 3 and Figure 6 Embodiments of the present invention will be described. The working process of the floating die punching die of the automobile roof is the same as that of the first embodiment, the difference is that the punching drive assembly 25, the die drive module 15 and the clamping cylinder 39 are controlled by two solenoid valves, and the two The solenoid valve is in turn connected to the power source. The solenoid valve 1 controls the punching drive assembly 25 , and the solenoid valve 2 controls the die drive module 15 and the clamping cylinder 39 . This control method is suitable for the case where the mold is linked with the automatic punching line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com