Apparatus for glass slicing

A glass and connecting rod technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing labor intensity, avoiding injuries and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

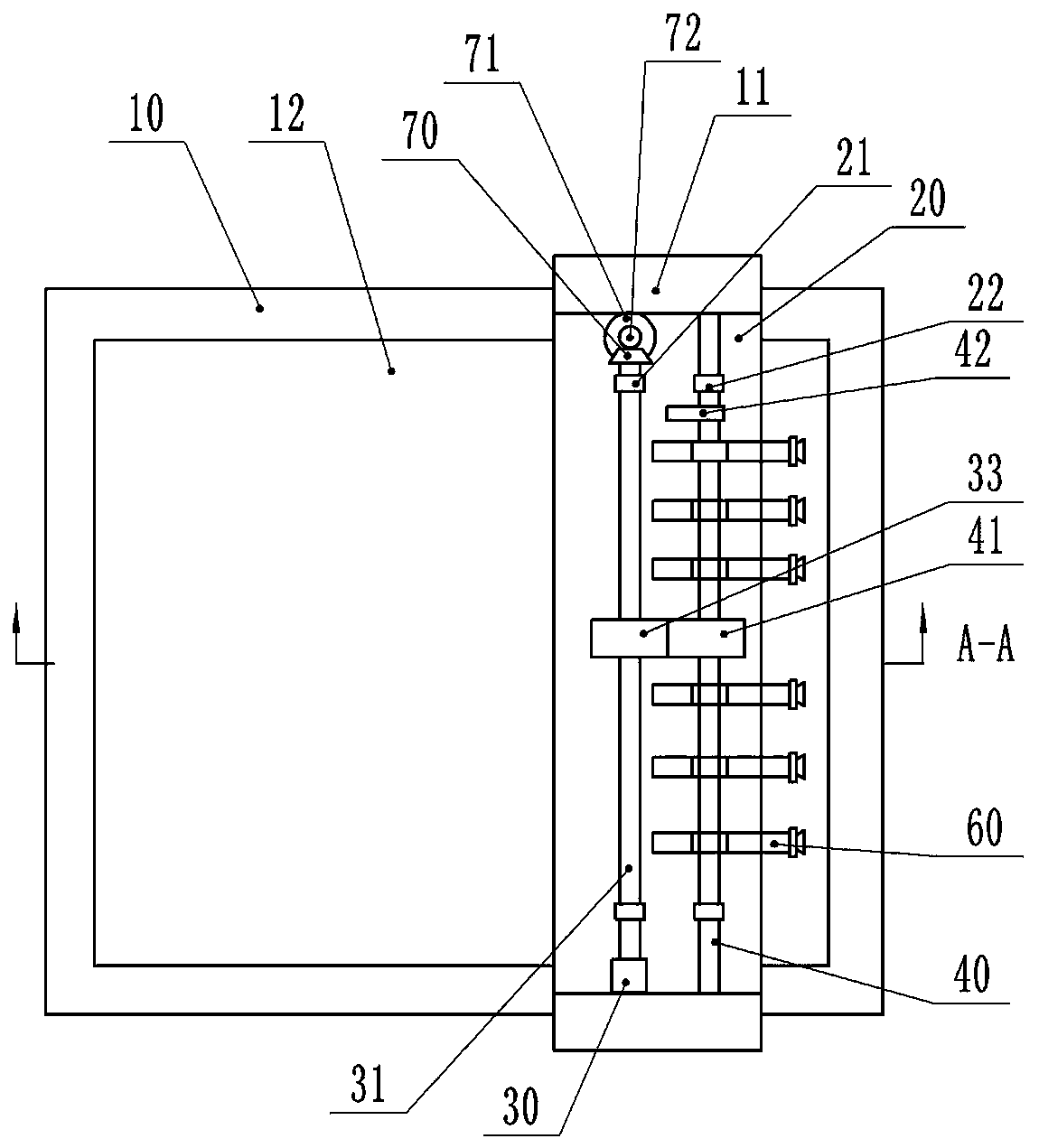

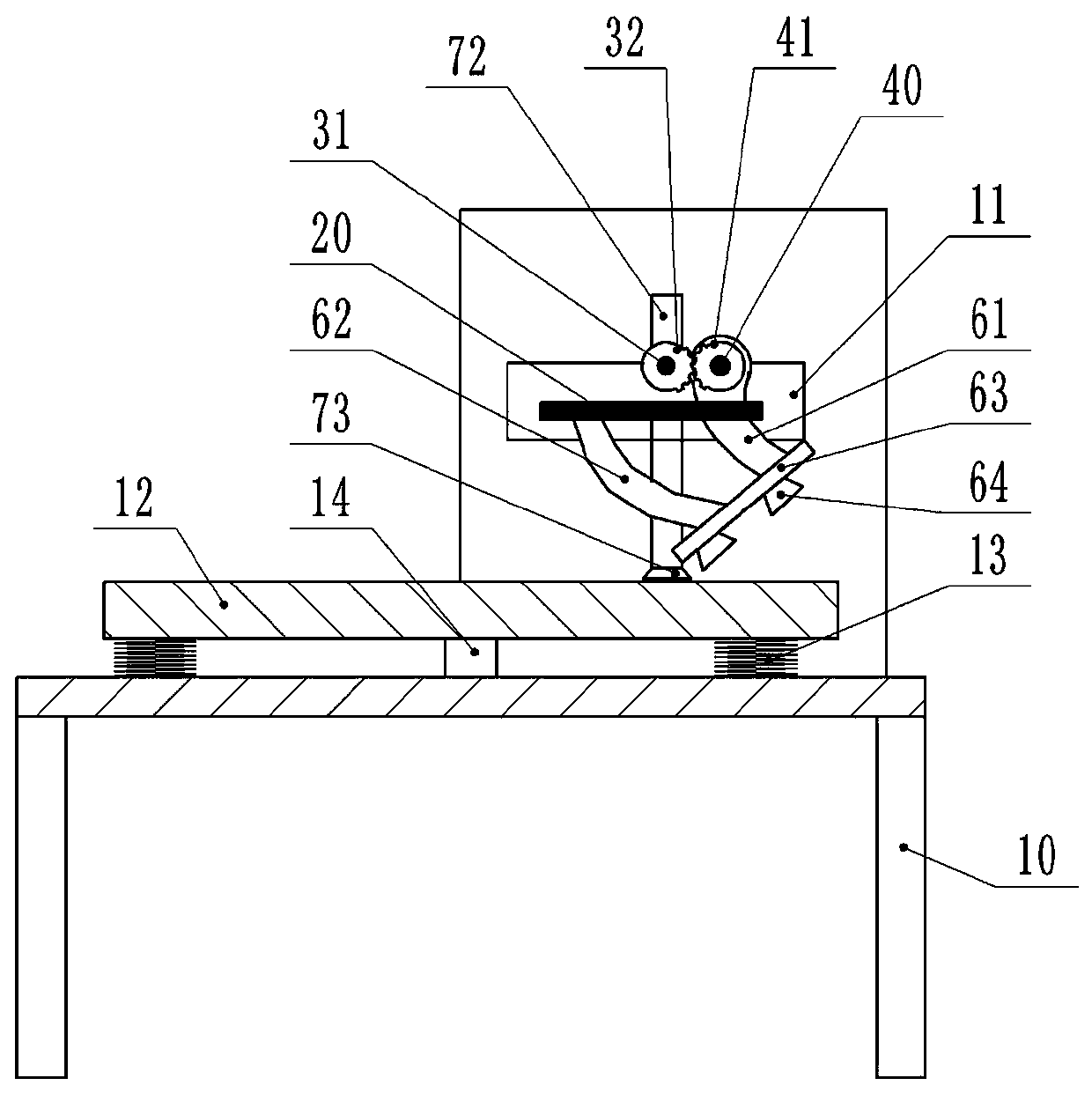

[0017] The reference signs in the drawings of the description include: bracket 10, support frame 11, receiving plate 12, first elastic member 13, fulcrum 14, support plate 20, first lug 21, second lug 22, motor 30, Connecting rod 31, first half gear 32, swing rod 40, second half gear 41, second elastic member 42, swing unit 60, swing rod 61, pull rod 62, support block 63, first suction cup 64, main bevel gear 70 , From the bevel gear 71, the pole 72, the second sucker 73.

[0018] Such as figure 1 , figure 2 As shown, the device for glass slicing includes a bracket 10, a support frame 11, a receiving plate 12, a first elastic member 13, a supporting plate 20, a connecting rod 31, a swing rod 40, a motor 30 and a support rod 72, and the receiving plate 12 is rotated at the center to be provided with a retractable rotating shaft, and the receiving plate 12 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com