Silicon wafer separation and loading machine for silicon wafer production

A chip loading machine and silicon chip technology, which is applied in the direction of conveyor objects, transportation and packaging, and final product manufacturing, etc., can solve the problems of silicon chip damage, lack of monitoring, poor loading efficiency, etc., to ensure integrity and reduce Damage, benefit-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

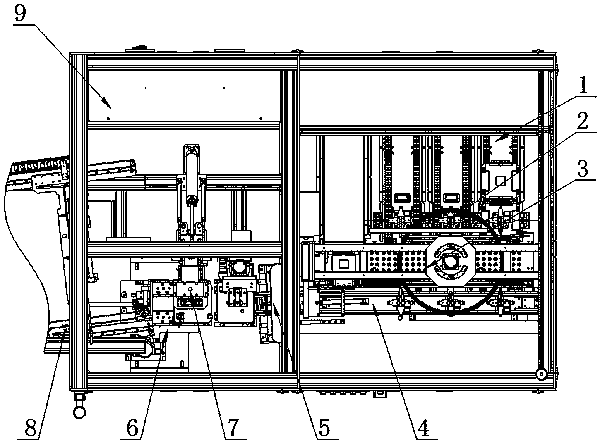

[0027]Embodiment 1, a kind of loading machine that is used for the production of silicon chip, comprises clip delivery module 1, splitting manipulator 2, splitting mechanism 3, conveying module 4, shaping module 5, insertion manipulator 6, empty Basket reflow module 7, flipping module 8, transplanting module 9, film loading machine frame 10; among them: clip conveying module 1, fragmentation manipulator 2, fragmentation mechanism 3, conveying module 4, shaping mold Group 5, inserting manipulator 6, empty basket return module 7, overturning module 8, and transplanting module 9 are all installed on the frame 10 of the chip loading machine, and a clip delivery module 1 and delivery module 4 are provided There is a fragmentation mechanism 3, a fragmentation manipulator 2 is installed on one side of the clip conveying module 1, a shaping module 5 is installed at the end of the conveying module 4, a turning module 7 is installed at the end of the shaping module 5, and the turning mod...

Embodiment 2

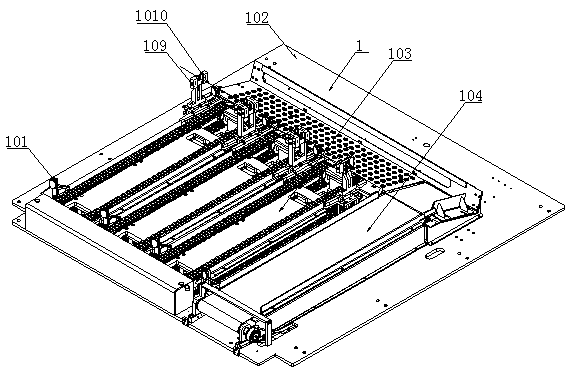

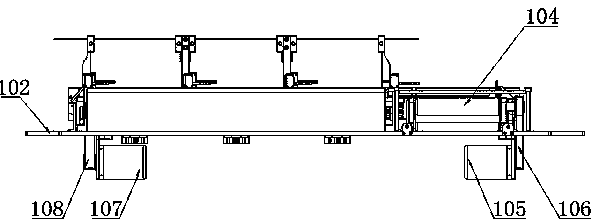

[0028] Embodiment 2, a chip loader for silicon wafer production, the clip conveying module 1 includes a first photoelectric sensor 101, a substrate assembly 102, a first conveying assembly 103, a first conveying assembly 104, and a first motor 105. The first high-torque synchronous toothed belt 106, the second motor 107, the second high-torque synchronous toothed belt 108, the air blowing plate 109, and the optical fiber 1010; wherein: the substrate assembly 102 is equipped with the second conveying assembly 104 and three A first conveying assembly 103, each first conveying assembly 103 both sides are equipped with air blowing board 109, each first conveying assembly 103 both sides are equipped with a first photoelectric sensor 101, substrate assembly 102 bottom is installed with a first Motor 105, second motor 107, the first motor 105 is connected with the first conveying assembly 104 through the first high torque synchronous belt 106, the second motor 107 is connected with th...

Embodiment 3

[0029] Embodiment 3, a kind of loading machine for the production of silicon wafers, the slicer mechanism 3 includes a bracket 301, a bearing seat 30, a rotating shaft 303, a turntable 304, a spacer 305, a first bearing 306, a second bearing 307, The third bearing 308, the fixed ring 309, the first coupling 3010, the third motor 3011, the first connecting plate 3012, the linear slider 3013, the mounting plate 3014, the vertical plate 3015, the adapter plate 3016, the suction cup 3017, the second Connecting plate 3018, third cylinder 3019; Wherein: bearing seat 302 is installed in the middle of support 301, bearing seat 302 is embedded with the bearing system that is formed by first bearing 306, second bearing 307, third bearing 308, fixed ring 309 , the rotating shaft 303 is installed on the lower part of the rotating disc 304, the rotating disc 304 is separated from the bearing seat 302 by the spacer 305, the fixed ring 309 is stuck in the slot of the rotating shaft 303, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com