Improvement scheme of fuel oil engine carburetor air throttle valve piston

A fuel engine and carburetor technology, applied to carburetors, engine components, machines/engines, etc., can solve problems such as unevenness, insufficient mixing and atomization of fuel and air, and achieve low cost investment, sufficient and fast combustion , the effect of pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

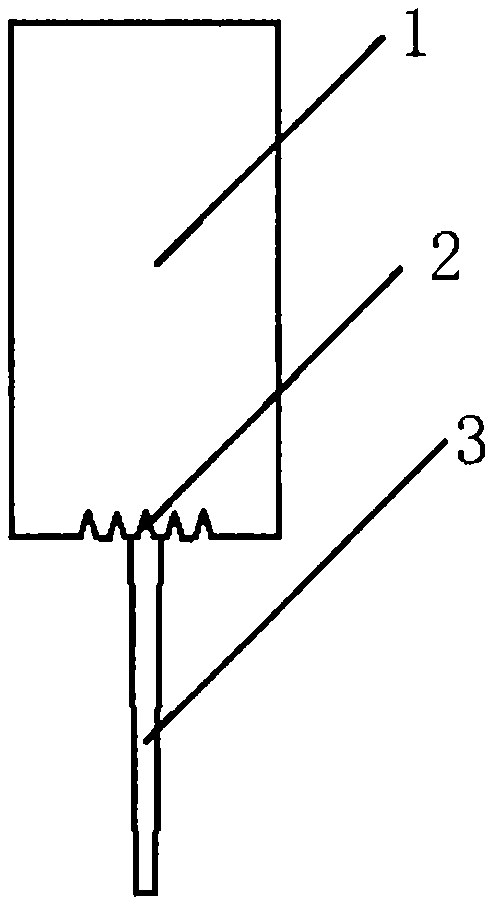

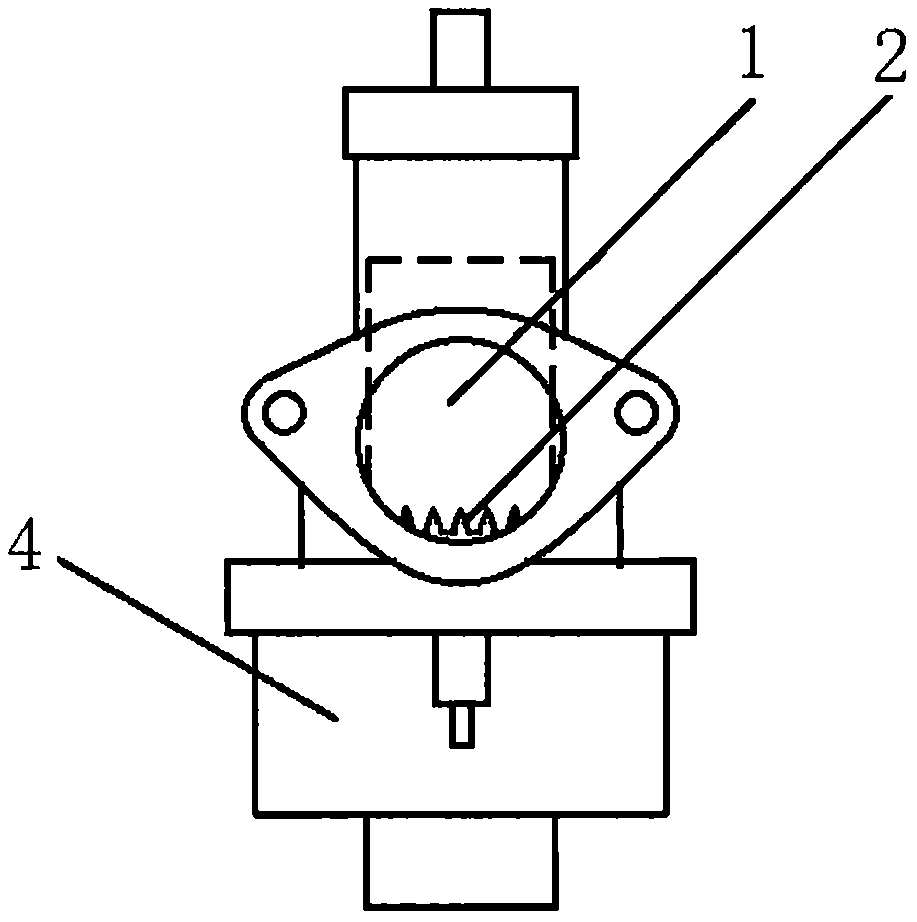

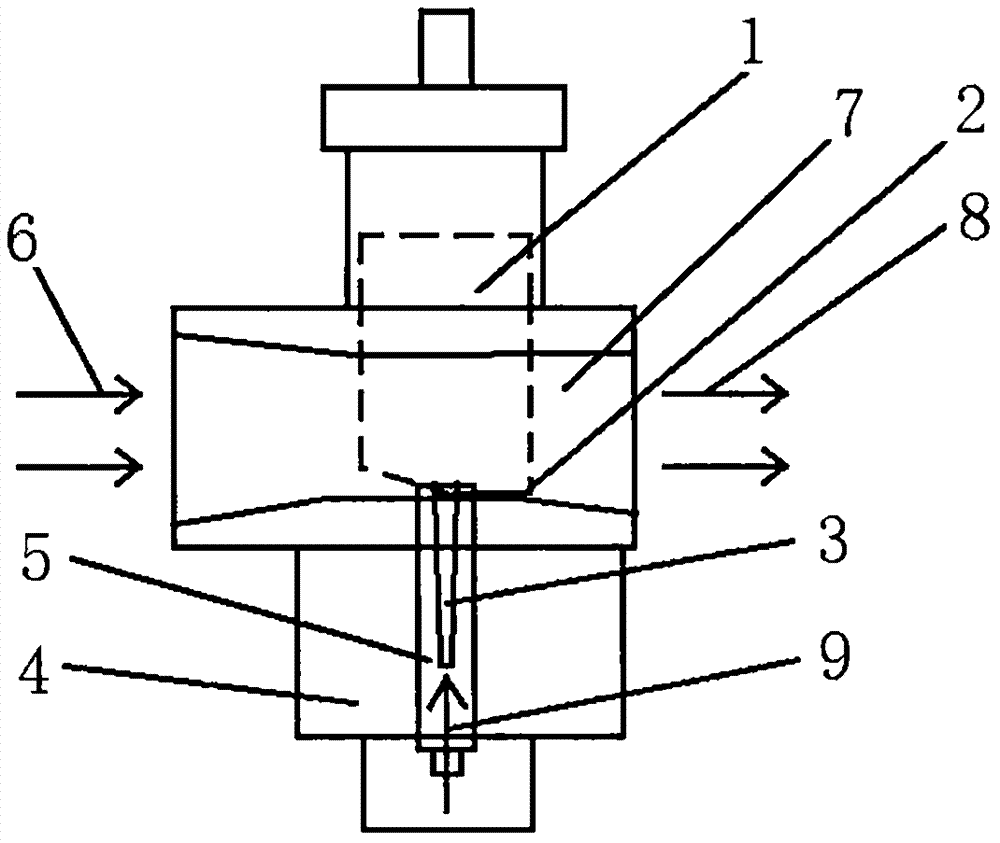

[0015] Place the lower part of the carburetor throttle valve piston toward the engine end, and process multiple guide grooves.

[0016] Description: The present invention can be used in fuel engine carburetors.

[0017] The above-mentioned embodiments of the present invention are merely examples of the present invention, rather than limiting the implementation of the present invention. For those skilled in the art, other changes and modifications in different forms can be made on the basis of the above description, and all implementation modes cannot be exhaustively listed here. All the technical solutions and extensions of processing a plurality of guide grooves at the lower end of the throttle valve piston of the carburetor towards the engine side still belong to the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com