Rotary high-temperature fused salt corrosion characteristic simulation system

A technology of high-temperature molten salt and simulation system, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of easy condensation, blockage of pipelines, and can not really reflect the corrosion of metal samples by corrosive media, so as to achieve the safety of the experimental system and reduce the Effect of eccentric movement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

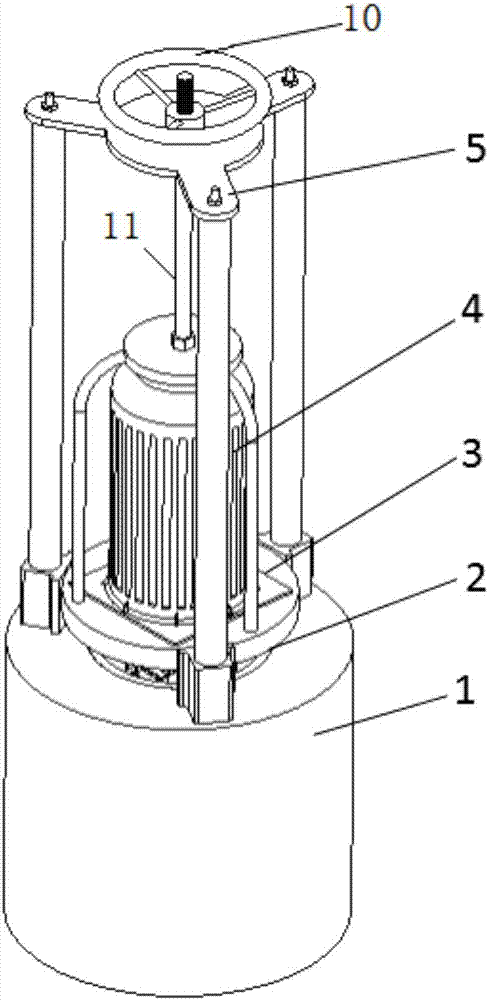

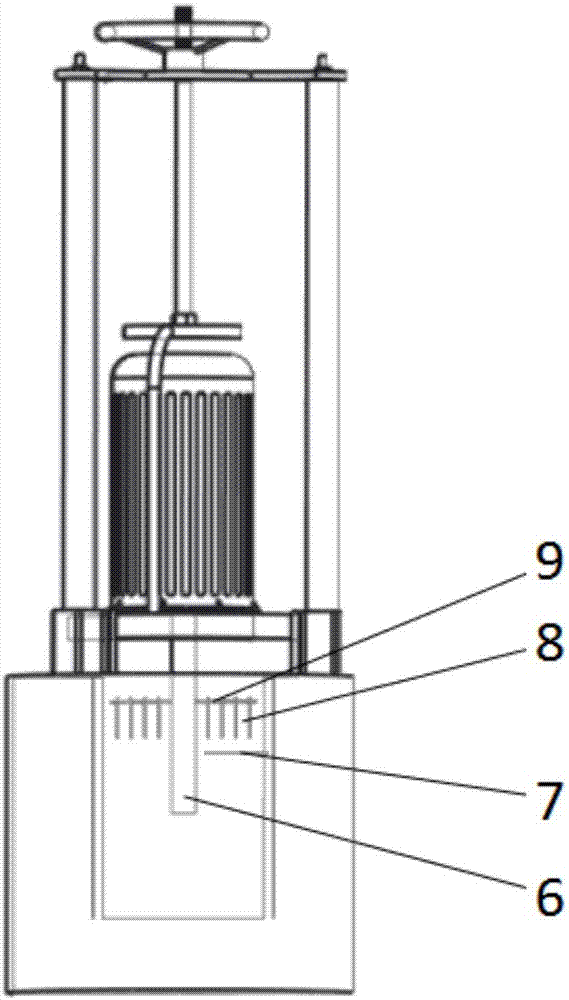

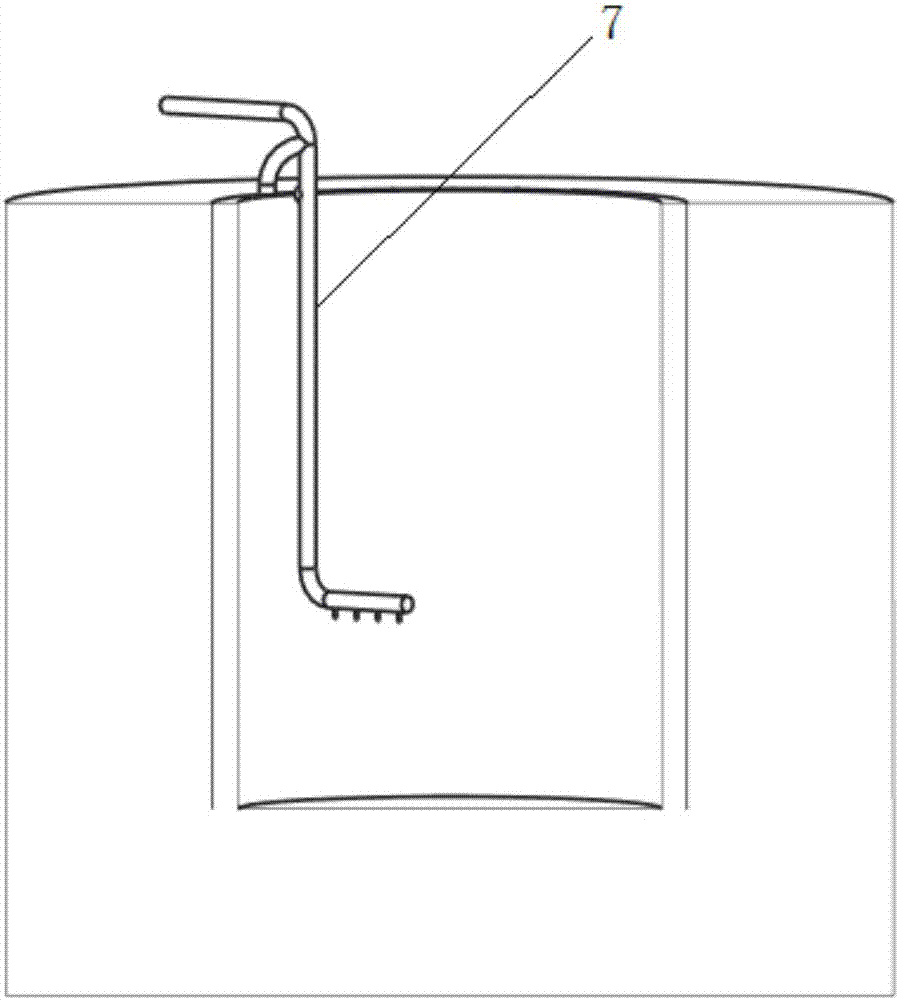

[0030] see figure 1 , a rotary high-temperature molten salt corrosion characteristic simulation system disclosed in the present invention includes a molten salt tank 1, a stirring device 2, a motor 4, and a motor lifting device for controlling the lifting of the motor 4. The molten salt tank 1 is also equipped with an electric motor. Heating device; one end of the stirring device 2 is fixed on the bottom of the motor 4, the other end extends into the molten salt tank 1, the stirring device 2 can be driven by the motor 4 to lift and rotate, and the stirring device 2 extends into one end of the molten salt tank 1 Place the sample piece 8 to be tested. During the test, the molten salt tank 1 is filled with high-temperature heat storage medium molten salt, and the molten salt composition is 60% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com