Method for online soft measurement of mill power in ore grinding process

A soft measurement and mill technology, applied in special data processing applications, instruments, biological neural network models, etc., can solve the problems of difficult application of semi-autogenous mill power soft measurement, too much noise interference, and difficulty in application, etc. loss, improve economic efficiency, increase throughput and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

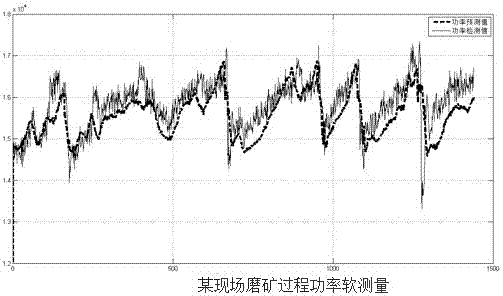

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

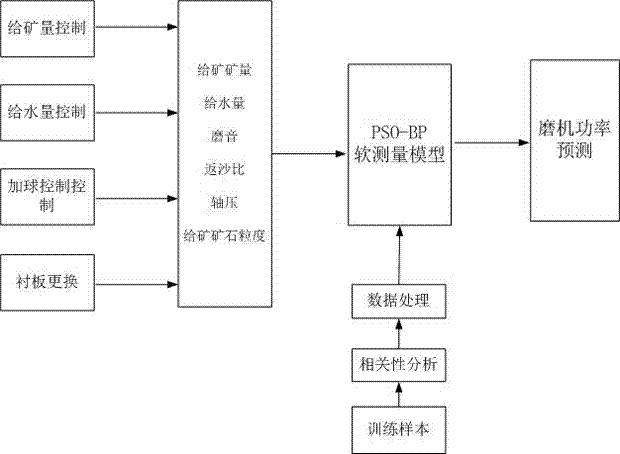

[0009] Soft-sensing technology is to select a group of measurable variables related to the estimated variable, construct a mathematical model with measurable variables as input and estimated variable as output, and use computer software programming to realize the estimation of important process variables. This process includes the selection of auxiliary variables, data collection and processing, soft sensor model establishment and online correction.

[0010] First, the choice of auxiliary variables. The selection of auxiliary variables is generally based on process mechanism analysis (such as material and energy balance relationship). In the measurable variable set, all original auxiliary variables related to the estimated variables are initially selected, and some of these variables may be related variables. On this basis, select an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com