Light emitting diode epitaxial wafer and fabrication method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as inability to merge and offset dislocations and defects, damage, and reduction in the growth quality of epitaxial wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

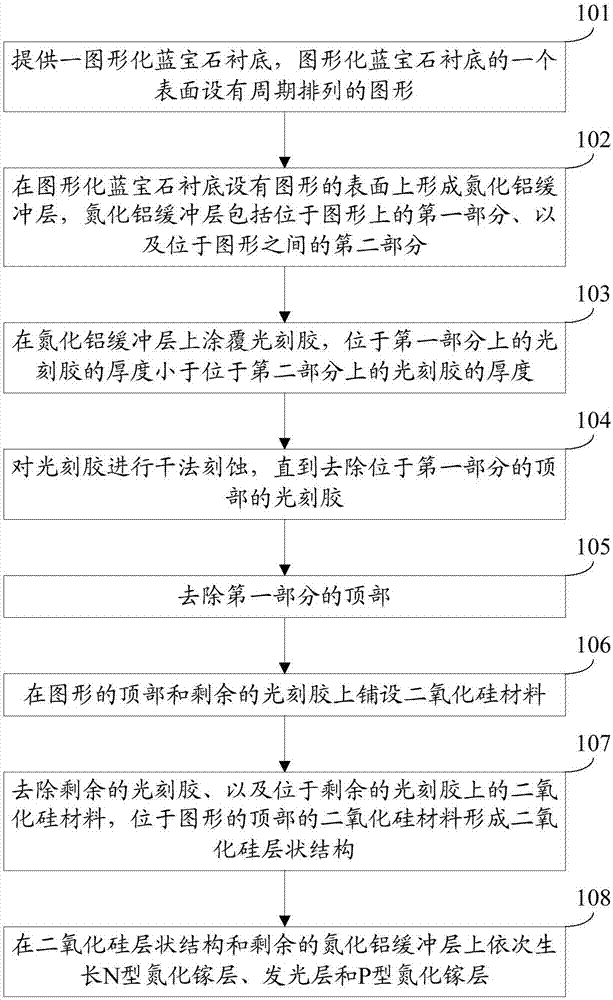

[0043] An embodiment of the present invention provides a method for manufacturing a light-emitting diode epitaxial wafer, see figure 1 , the production method includes:

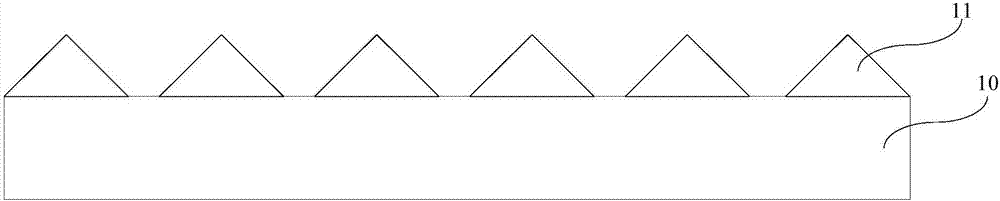

[0044] Step 101: Provide a patterned sapphire substrate, one surface of the patterned sapphire substrate is provided with patterns arranged periodically.

[0045] Figure 2a It is a schematic structural diagram of the epitaxial wafer after step 101 is executed. Wherein, 10 represents a patterned sapphire substrate, and 11 represents a pattern. Such as Figure 2a As shown, several patterns 11 are arranged at equal intervals on one surface of the patterned sapphire substrate 10 .

[0046] Optionally, the maximum distance between two points on the bottom surface of a figure may be equal to the distance between two adjacent figures.

[0047] Wherein, the bottom surface of the figure is the surface in contact with the patterned sapphire substrate, and the maximum distance between two points on the bottom surf...

Embodiment 2

[0111] An embodiment of the present invention provides a method for manufacturing a light-emitting diode epitaxial wafer, and the method provided in this embodiment is a specific implementation of the method provided in Embodiment 2. see image 3 , the production method includes:

[0112] Step 201: Provide a patterned sapphire substrate, one surface of the patterned sapphire substrate is provided with patterns arranged periodically, the period of the patterns is 3 μm, and the height of the patterns is 1.6 μm.

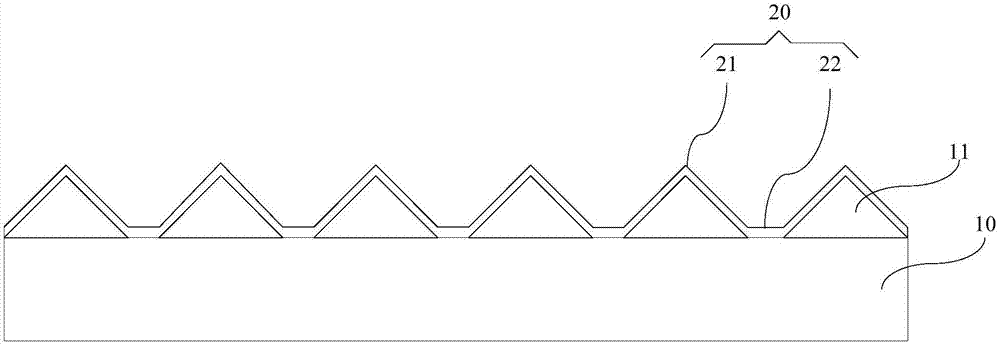

[0113] Step 202: forming an aluminum nitride buffer layer with a thickness of 300 nm on the surface of the patterned sapphire substrate provided with patterns, the aluminum nitride buffer layer including a first part on the pattern and a second part between the patterns.

[0114] Step 203: Coating photoresist on the aluminum nitride buffer layer, the thickness of the photoresist on the first part is smaller than the thickness of the photoresist on the second part, the ...

Embodiment 3

[0122] An embodiment of the present invention provides a light-emitting diode epitaxial wafer. The epitaxial wafer provided in this embodiment can be manufactured by the manufacturing method provided in Embodiment 1 or Embodiment 2. Refer to Figure 4 , the light-emitting diode epitaxial wafer includes a patterned sapphire substrate 10, an aluminum nitride buffer layer 20, a silicon dioxide layered structure 30, an N-type gallium nitride layer 40, a light-emitting layer 50, and a P-type gallium nitride layer 60. One surface of the patterned sapphire substrate 10 is provided with periodically arranged patterns 11, the silicon dioxide layered structure 30 is arranged on the top of each pattern 11, and the aluminum nitride buffer layer 20 is arranged on the top of the patterned sapphire substrate 10 except the pattern 11 In the area other than the N-type gallium nitride layer 40 is arranged on the aluminum nitride buffer layer 20 and the silicon dioxide layered structure 30, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com