Repair method of heavy metal polluted soil

A technology of polluted soil and remediation method, applied in the restoration of polluted soil and other directions, can solve the problems of slow effect, unstable remediation effect, insignificant effect of phytoremediation method, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

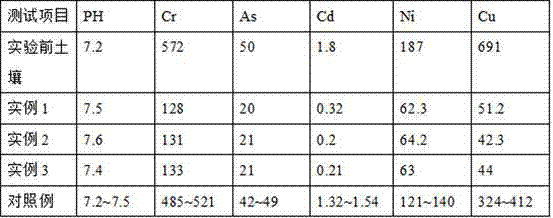

Examples

example 1

[0029] Liquid preparation method:

[0030] a. In parts by weight, 70 parts of water, 30 parts of peptone, 17 parts of yeast extract, 15 parts of glucose, and 4 parts of agar were mixed and sterilized at high temperature to obtain a nutrient solution;

[0031] b. According to the mass ratio of 100:1, put the nutrient solution and pig manure into the fermenter, ferment for 5 days at a temperature of 25°C, filter, collect the fermented liquid, and obtain the liquid.

[0032] Carbonized stalks are obtained by carbonizing corn stalks at a temperature of 300°C and collecting carbonized products.

[0033] The repairing method of heavy metal polluted soil of the present invention, comprises the steps:

[0034] (1) Lay pipes inside the heavy metal contaminated soil, the depth is 40cm, the distance between the pipes is 20cm, use the pipes for aeration, the aeration rate is 8L / min, after aeration for 20min, the liquid is delivered to the soil at 5L / min , the delivery time is 15min;

...

example 2

[0039] Liquid preparation method:

[0040] a. In parts by weight, 75 parts of water, 35 parts of peptone, 19 parts of yeast extract, 18 parts of glucose, and 5 parts of agar were mixed and sterilized at high temperature to obtain a nutrient solution;

[0041] b. According to the mass ratio of 110:1.5, put the nutrient solution and pig manure into the fermenter, ferment for 6 days at a temperature of 28°C, filter, collect the fermented liquid, and obtain the liquid.

[0042] Carbonized stalks are obtained by carbonizing corn stalks at a temperature of 310°C and collecting carbonized products.

[0043] The repairing method of heavy metal polluted soil of the present invention, comprises the steps:

[0044] (1) Lay pipes inside the heavy metal polluted soil, the depth is 45cm, the distance between the pipes is 25cm, use pipes for aeration, the aeration rate is 9L / min, after 25min of aeration, transport to the soil at 5.5L / min Liquid, delivery time is 18min;

[0045] (2) After ...

example 3

[0049] Liquid preparation method:

[0050] a. In parts by weight, 80 parts of water, 40 parts of peptone, 23 parts of yeast extract, 20 parts of glucose, and 7 parts of agar were mixed and sterilized at high temperature to obtain a nutrient solution;

[0051] b. According to the mass ratio of 120:2, put the nutrient solution and pig manure into the fermenter, ferment for 7 days at a temperature of 30°C, filter, collect the fermented liquid, and obtain the liquid.

[0052] Carbonized stalks are obtained by carbonizing corn stalks at a temperature of 320°C and collecting carbonized products.

[0053] The repairing method of heavy metal polluted soil of the present invention, comprises the steps:

[0054] (1) Lay pipes inside the heavy metal contaminated soil, the depth is 50cm, the distance between the pipes is 30cm, use the pipes for aeration, the aeration rate is 10L / min, after 30min of aeration, the liquid is delivered to the soil at 6L / min , the delivery time is 20min;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com