High-performance synchronous grouting modifier for shielding construction as well as preparation method and application thereof

A synchronous grouting and modifier technology, which is applied in the field of mud-water balance shield construction materials, can solve the problems of decreased support strength, uneven grout deformation, and unsatisfactory grouting quality, achieving air-entraining and water-retaining performance, Avoid freeze-thaw damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

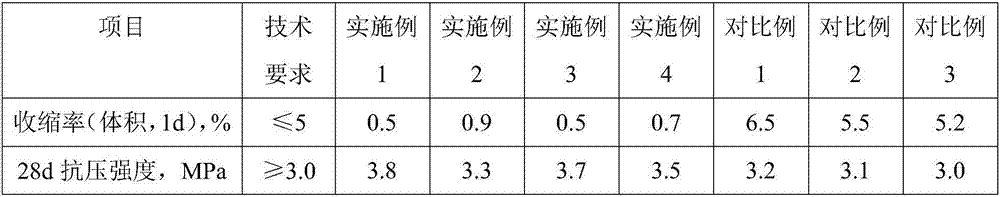

Examples

Embodiment 1

[0037] The high-performance synchronous grouting modifier for shield tunneling consists of the following components: 1.3% water reducer, 3.5% thickener, 0.6% antifreeze, and the balance is water;

[0038] The water reducer is HSB aliphatic high-efficiency water reducer;

[0039] Thickener is made up of bentonite and hydroxypropyl methylcellulose, and the mass ratio of bentonite and hydroxypropyl methylcellulose is 1:1;

[0040] Antifreeze is mortar antifreeze.

[0041] Add this high-performance synchronous grouting modifier for shield tunneling into the synchronous grouting slurry

[0042] The amount (Kg) of each material required to prepare 1 cubic meter of improved mortar is as follows:

[0043] Cement: 50, fine sand: 1250, fly ash: 232, bentonite: 72, water: 402, synchronous grouting modifier: 8.

[0044] At 25°C, prepare synchronous grouting slurry according to the above ratio, stir well and let stand. No segregation phenomenon occurred after standing for 5 minutes, an...

Embodiment 2

[0046] The high-performance synchronous grouting modifier for shield tunneling consists of the following components: 1% water reducer, 3% thickener, 0.6% antifreeze, and the balance is water;

[0047] The water reducer is HSB aliphatic high-efficiency water reducer;

[0048] The thickener is made up of bentonite and hydroxypropyl methylcellulose, and the mass ratio of bentonite and hydroxypropyl methylcellulose is 1:1.1;

[0049] Antifreeze is mortar antifreeze.

[0050] Add this high-performance synchronous grouting modifier for shield tunneling into the synchronous grouting slurry

[0051] The amount (Kg) of each material required to prepare 1 cubic meter of improved mortar is as follows:

[0052] Cement: 50, fine sand: 1250, fly ash: 232, bentonite: 72, water: 402, synchronous grouting modifier: 8.

[0053] At 25°C, prepare synchronous grouting slurry according to the above ratio, stir well and let stand. No segregation phenomenon occurred after standing for 5 minutes, an...

Embodiment 3

[0055] The high-performance synchronous grouting modifier for shield tunneling consists of the following components: 1.5% water reducer, 4% thickener, 0.8% antifreeze, and the balance is water;

[0056] The water reducer is HSB aliphatic high-efficiency water reducer;

[0057] Thickener is made up of bentonite and hydroxypropyl methylcellulose, and the mass ratio of bentonite and hydroxypropyl methylcellulose is 1:1;

[0058] Antifreeze is mortar antifreeze.

[0059] Add this high-performance synchronous grouting modifier for shield tunneling into the synchronous grouting slurry

[0060] The amount (Kg) of each material required to prepare 1 cubic meter of improved mortar is as follows:

[0061] Cement: 50, fine sand: 1250, fly ash: 232, bentonite: 72, water: 402, synchronous grouting modifier: 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com