Preparation method of micro-nanoparticle synergic interlaminar toughened bismaleimide/carbon fiber composite material

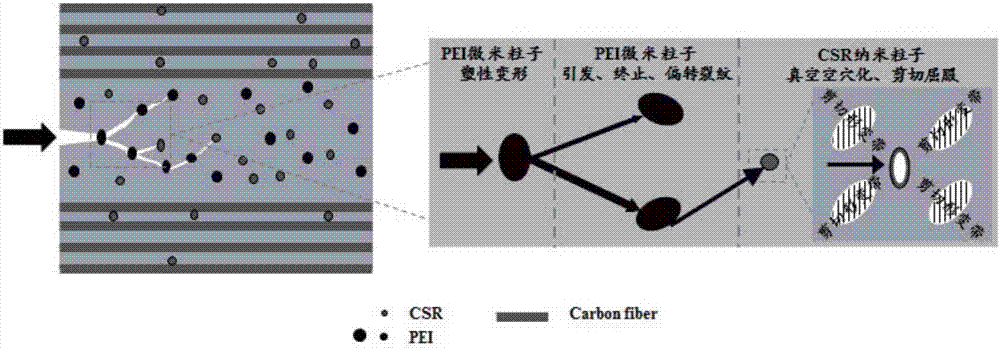

A technology of micro-nano particles and composite materials, which is applied in the field of preparation of micro-nano particles synergistic interlayer toughened double horse/carbon fiber composite materials, can solve problems such as complex processes, reduce reactivity, weak anti-damage ability, improve layer The effect of fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

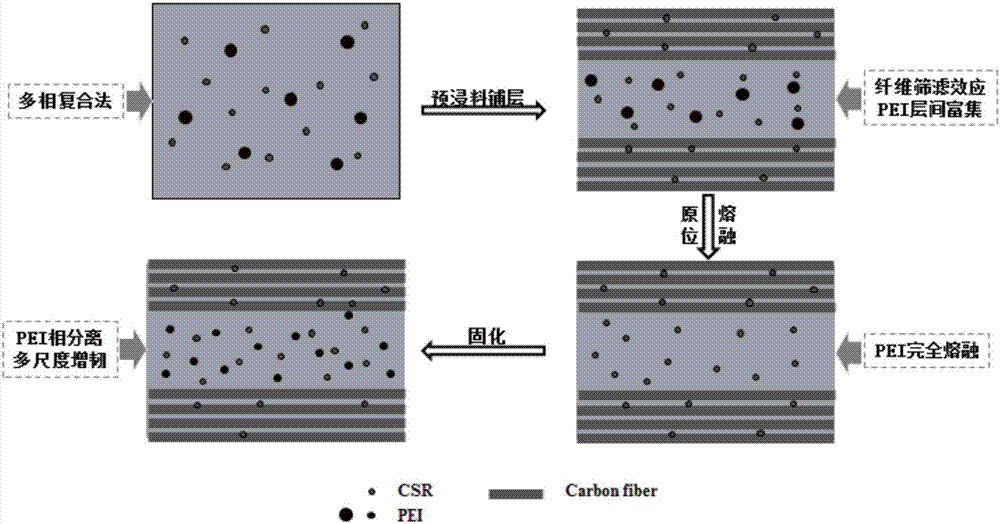

[0021] (1) "Multiphase compounding" method: Add PEI micron particles to the liquid toughening agent containing diallyl bisphenol A (DABPA) at 100°C, and stir it evenly, and then add Bima micron powder (molar ratio BMI: DABPA=1:0.87), after continuing to stir evenly, place it on a three-roll mill for physical blending to obtain a low-viscosity resin system with good dispersibility, in which the mass fraction of PEI micron particles is 4%; (2) (1) ) The obtained double horse resin system is coated at 70°C and combined with T800 carbon fiber reinforcement at 100°C to prepare a prepreg; (3) The prepreg obtained in (2) is cut, layered, and molded. , To obtain a dual-horse / carbon fiber composite material toughened by PEI micron particles.

Embodiment 2

[0023] (1) "Multiphase composite" method: Add PEI micro-particles and core-shell nanoparticles to a liquid toughening agent containing diallyl bisphenol A (DABPA) at 85°C, and mix initially, and then add Shuangma powder (Molar ratio BMI:DABPA=1:0.87), after continuing to stir uniformly, place it on a three-roll mill for physical blending to obtain a low-viscosity resin system with good dispersibility, in which the mass fraction of PEI micron particles is 3%. The mass fraction of core-shell nanoparticles is 1%; (2) The Bima resin system obtained in (1) is coated at 60°C and combined with T800 carbon fiber reinforcement at 90°C to prepare a prepreg; (3) ) The prepreg obtained in (2) is cut, layered, and compression molded to obtain a bima / carbon fiber composite material toughened by PEI micron particles between layers.

Embodiment 3

[0025] (1) "Multiphase composite" method: Add PEI micro-particles and core-shell nanoparticles to a liquid toughening agent containing diallyl bisphenol A (DABPA) at 70°C, and mix initially, and then add Shuangma powder (Molar ratio BMI:DABPA=1:0.87), after continuing to stir evenly, place it on a three-roll mill for physical blending to obtain a low-viscosity resin system with good dispersibility, in which the quality of PEI micro-particles and core-shell nanoparticles The fraction is 2% each; (2) Coat the Bima resin system obtained in (1) at 50°C, and heat-press and compound with T800 carbon fiber reinforcement at 80°C to prepare prepregs; (3) Put (2) The obtained prepreg is cut, layered, and compression molded to obtain a bima / carbon fiber composite material toughened by PEI micron particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com