Pulverizing system with external feeding function and blast furnace blowing system

A technology of pulverizing system and feeding system, applied in blast furnace, blast furnace details, blast furnace parts, etc., can solve problems such as poor grinding effect, corrosion damage, and reducing the grindability of raw coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

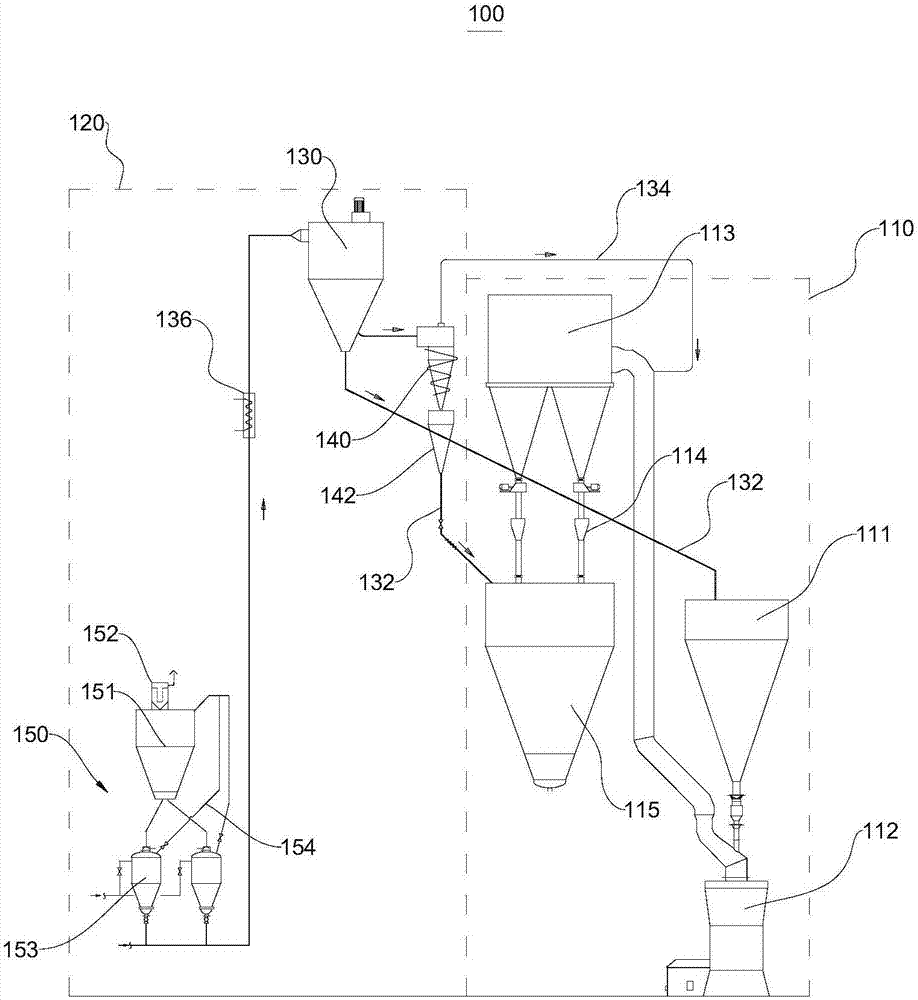

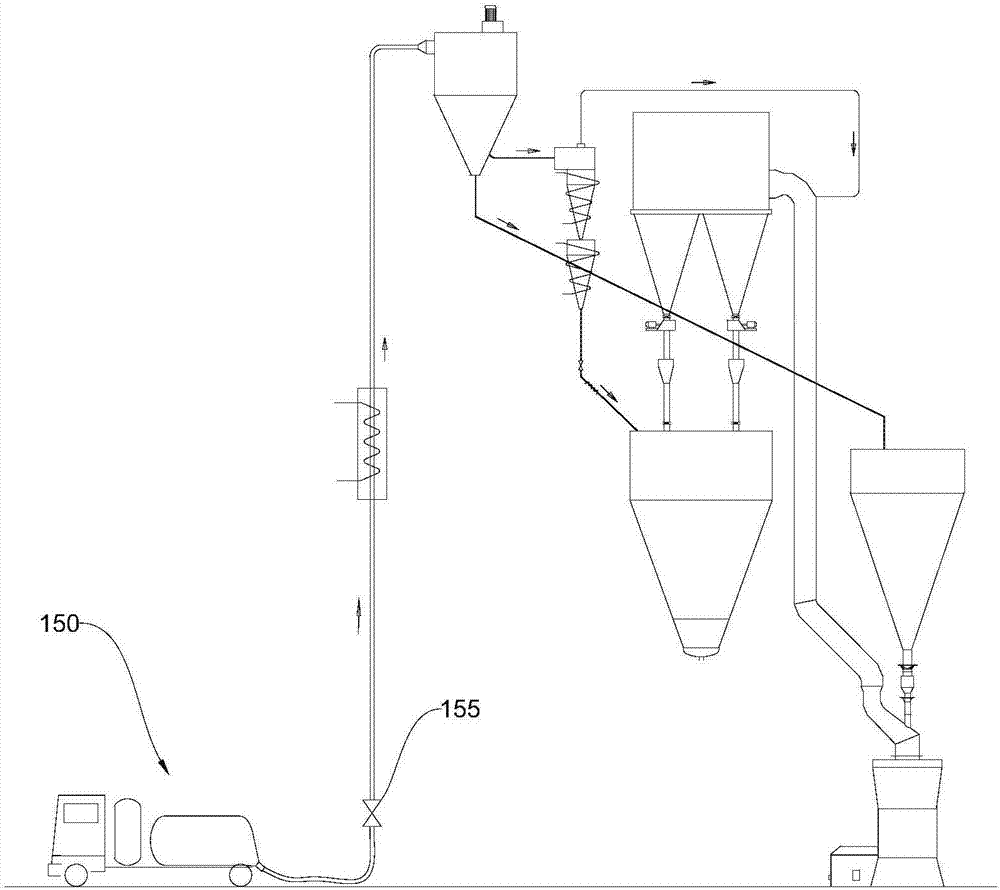

[0037] figure 1 It is a schematic structural diagram of a pulverizing system 100 with external feeding function in Embodiment 1 of the present invention. Please refer to figure 1 , the present embodiment provides a pulverizing system 100 with an external feeding function, which includes a pulverized coal preparation system 110 and an external feeding system 120, and the external feeding system 120 communicates with the pulverized coal preparation system 110 through a pipeline to CDQ coke powder, dedusting powder or other auxiliary material powders are sent to the pulverized coal preparation system 110 to complete the preparation and storage, which is convenient for blast furnace coal injection.

[0038] The pulverized coal preparation system 110 includes a raw coal bunker 111 , a coal mill 112 , a pulverized coal bunker 115 and a filtering device 113 . In this embodiment, the raw coal bunker 111, the coal mill 112, the filtering device 113, and the pulverized coal bunker 115...

Embodiment 2

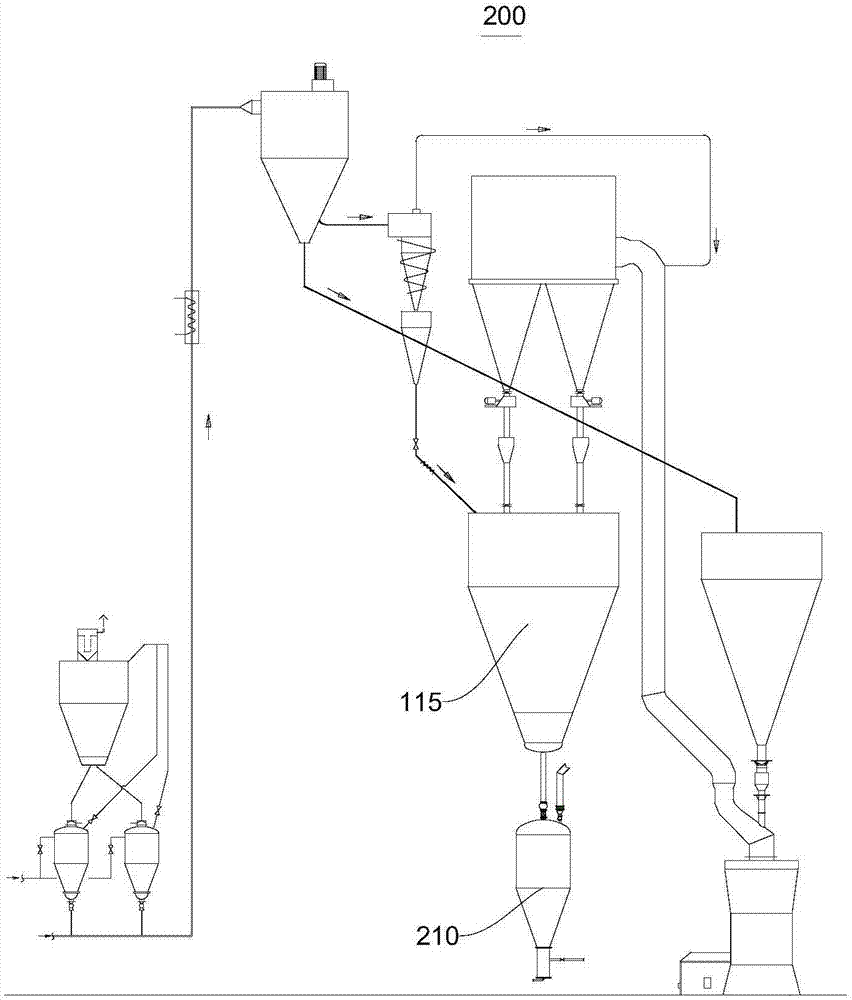

[0052] Figure 4 It is a schematic structural diagram of a pulverizing system 300 with external feeding function in Embodiment 2 of the present invention. Please combine figure 1 and Figure 4 , this embodiment provides a pulverizing system 300 with an external feeding function, which is roughly the same in structure as the pulverizing system 100 of the first embodiment, the difference between the two is that the mechanism of the external feeding system 320 in this embodiment is different. different.

[0053] The external feeding system 320 only includes the cyclone dust collector 140 and the coal storage bin 142 connected to the powder outlet of the cyclone dust collector 140 , without the classification device 130 . The inlet of the cyclone dust collector 140 is connected to the outlet of the pneumatic conveying device 150 through a pipeline, and the exhaust gas outlet of the cyclone dust collector 140 is connected to the pipeline at the inlet of the filter device 113 thr...

Embodiment 3

[0057] Figure 5 It is a schematic structural diagram of the milling system 400 in Embodiment 3 of the present invention. Please combine figure 1 and Figure 5 , this embodiment provides a pulverizing system 400 with an external feeding function, which has roughly the same structure as the pulverizing system 100 in Embodiment 1, the difference between the two is that the mechanism of the external feeding system 420 in this embodiment is different .

[0058] In this embodiment, the external feeding system 420 only includes the classification device 130 and does not include the cyclone dust collector 140 (see figure 1 ), the inlet of the classification device 130 is communicated with the outlet of the pneumatic conveying device 150, the coarse powder outlet of the classification device 130 is communicated with the raw coal bunker 111 through the powder feeding pipeline 132, and the fine powder outlet of the classification device 130 is communicated with the pipeline at the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com