Single-measuring-head scanning and repair device and method for damaged parts

A technology of single probe and probe, which is applied in the field of single probe scanning and repairing devices, can solve the problems of increasing the difficulty of point cloud reconstruction, increasing equipment manufacturing cost, and long waiting time for repairing, so as to shorten the scanning time and repairing waiting time, The effect of reducing hardware cost and improving reconstruction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

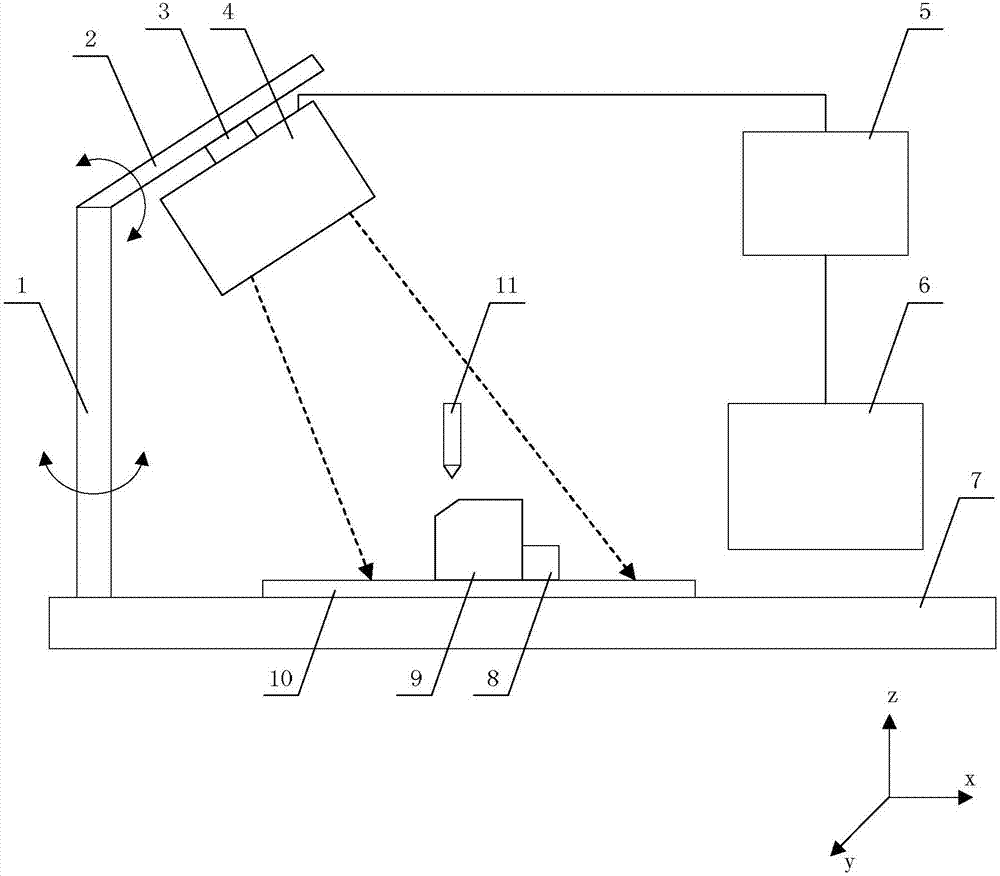

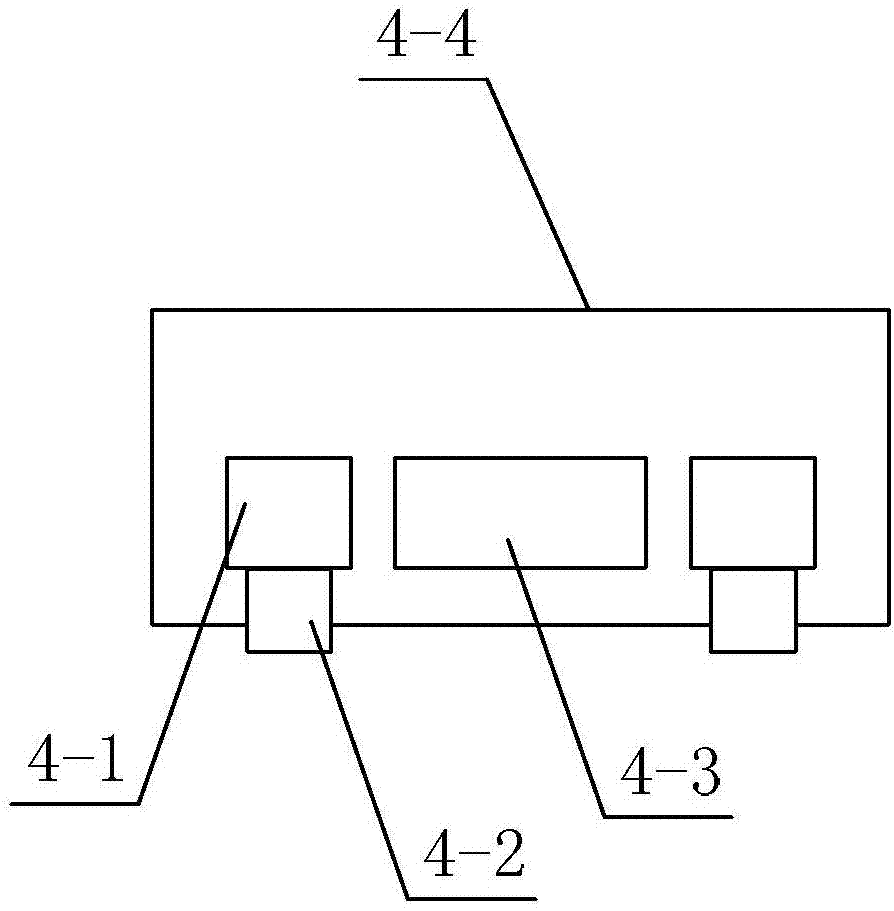

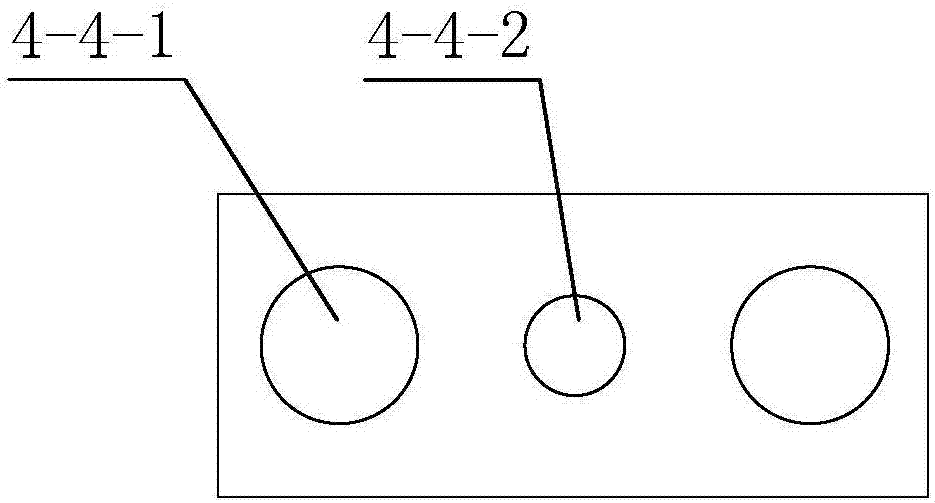

[0033] Attached below Figure 1-10 The present disclosure is described in detail with specific embodiments;

[0034] In one embodiment, the present disclosure discloses a single-probe scanning and repairing device for damaged parts, the device includes a three-dimensional optical scanning system and a laser cladding repairing system;

[0035] The three-dimensional optical scanning system includes an acquisition unit and a data generation unit;

[0036] The acquisition unit utilizes a single measuring head to acquire grating stripe images on the surface of the damaged part;

[0037] The data generation unit is used to process the collected grating stripe image to generate three-dimensional point cloud data on the surface of the damaged part, and use the three-dimensional point cloud data to generate a digital model of the defect area of the damaged part;

[0038] The laser cladding repair system repairs the damaged part according to the digital model of the defect.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com