Non-transparent environment-friendly nonwoven wallpaper

An environmental protection and wallpaper technology, applied in the direction of textiles and papermaking, papermaking, paper, etc., can solve the problems of low production cost, low opacity, high opacity, etc., and achieve the goal of improving light fastness, high opacity, and strong light scattering ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

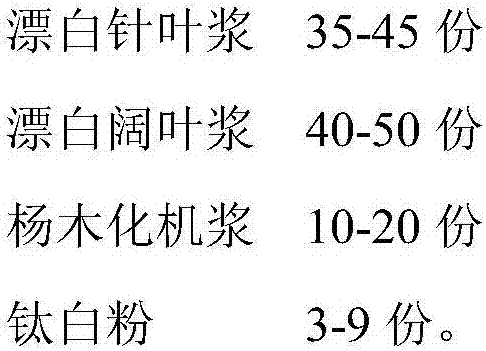

[0027] The opaque environment-friendly non-woven wallpaper is made of the following raw materials in parts by weight:

[0028]

[0029] The preparation method comprises the following steps:

[0030] (1) Crushing, refining and pulping:

[0031] Put the proportioned amount of bleached softwood pulp and bleached hardwood pulp into the pulper at the same time for disintegration, and put them into the pre-grinding pool A after disintegration; put the proportioned amount of poplar chemical pulp into the pulper as well Disintegrate, after disintegrating, put it into the pre-grinding pool B;

[0032] The disintegrated bleached coniferous pulp and bleached hardwood pulp are ground for later use in a semi-free and semi-sticky manner; The ones are sent to the slurry mixing tank in proportion, then titanium dioxide is added, and white water is added to dilute to the required concentration for later use;

[0033] (2) Paper copying:

[0034] The prepared slurry is pumped to the headb...

Embodiment 2

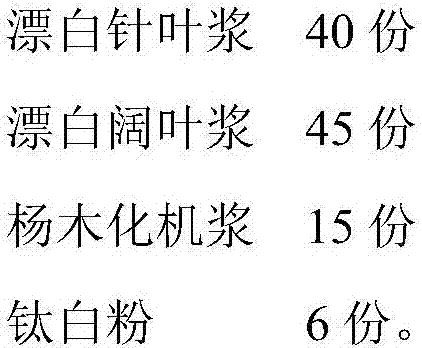

[0037] The opaque environment-friendly non-woven wallpaper is made of the following raw materials in parts by weight:

[0038]

[0039]

[0040] The preparation method is the same as in Example 1.

[0041] After testing, the non-woven wallpaper obtained in this embodiment with a quantitative weight of 110 grams has an opacity of 90-92.

Embodiment 3

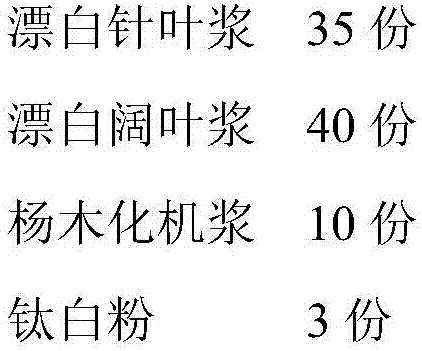

[0043] The opaque environment-friendly non-woven wallpaper is made of the following raw materials in parts by weight:

[0044]

[0045] The preparation method is the same as in Example 1.

[0046] After testing, the non-woven wallpaper obtained in this embodiment with a quantitative weight of 110 grams has an opacity of 88-90.

PUM

| Property | Measurement | Unit |

|---|---|---|

| opacity | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com