Fabrication method of sandwich thermal insulation inline composite wall with lead pipe-coarse sand energy-dissipating and shock-absorbing key

A composite wall and composite wall panel technology, which is applied in the direction of walls, earthquake-proof, protective buildings/shelters, etc., can solve the problems of poor thermal insulation performance, slow construction speed, low seismic energy consumption capacity, etc., and achieve improved thermal insulation effect , high production efficiency and high level of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in combination with specific implementation examples.

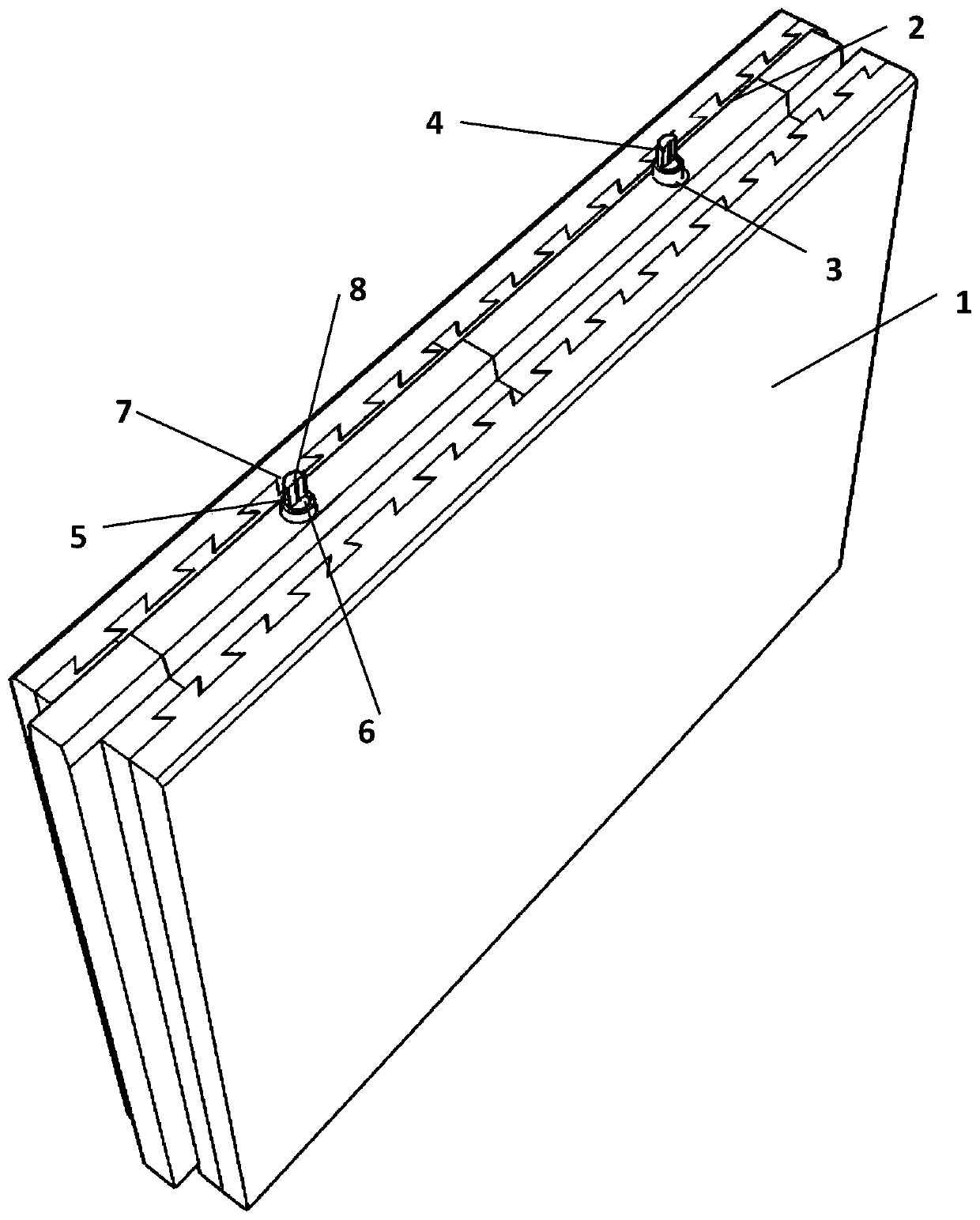

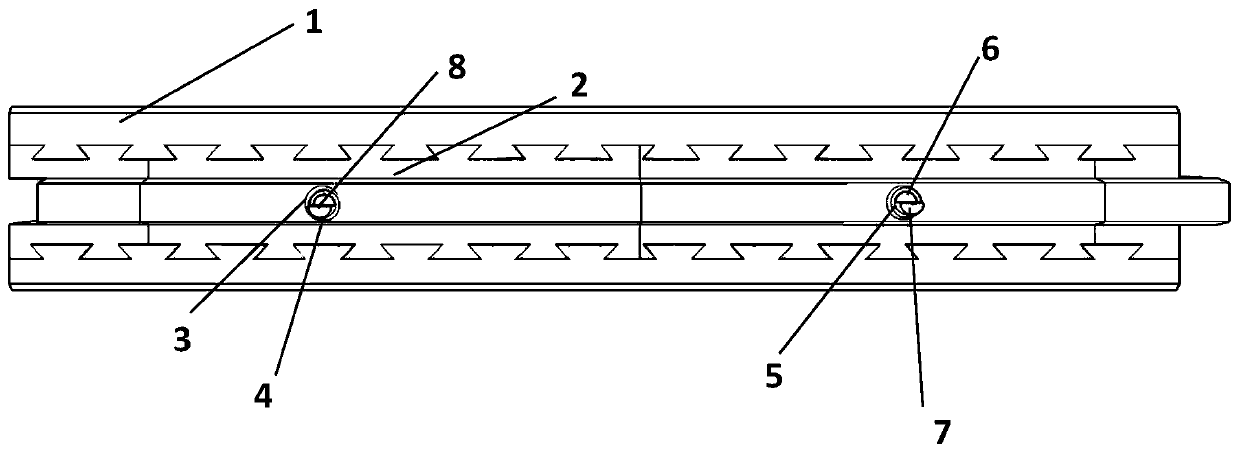

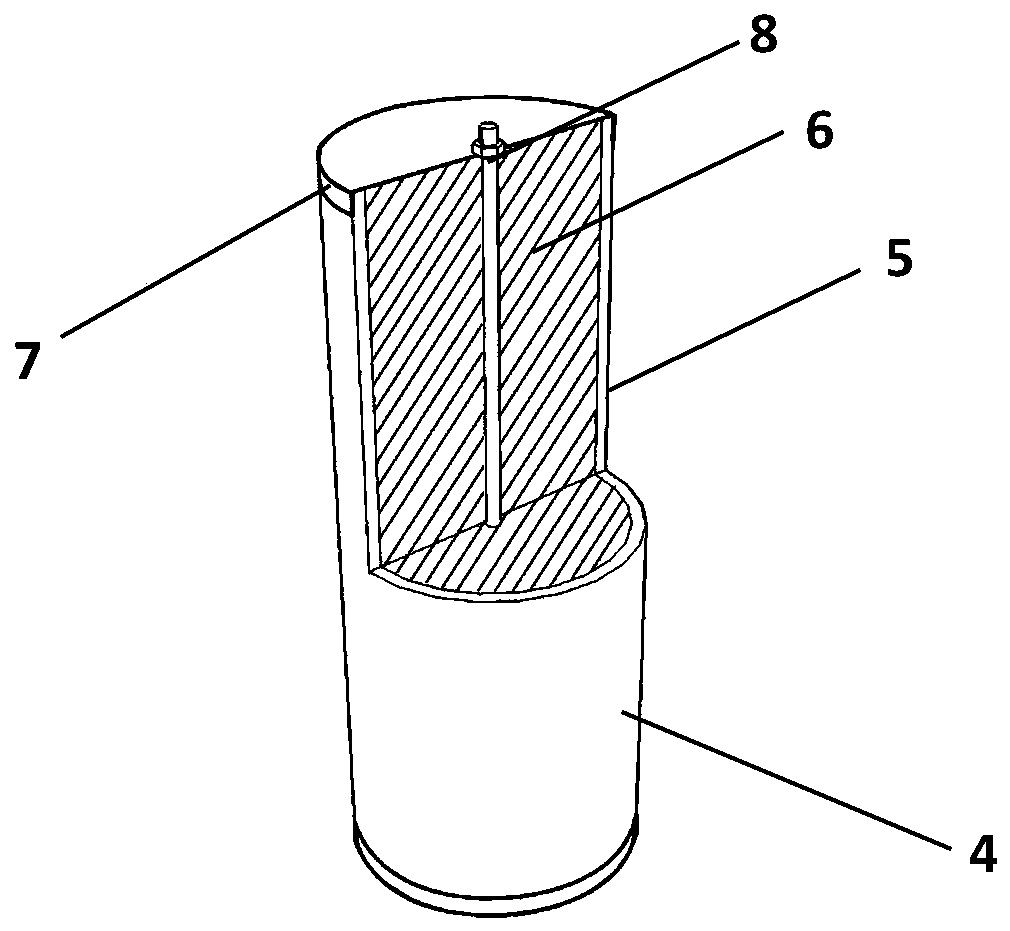

[0041] Such as figure 1 As shown, the sandwich thermal insulation in-line composite wall with lead pipe-coarse sand energy-dissipating and shock-absorbing keys of the present invention, the wall structure is composed of recycled concrete wall panels 1, EPS insulation modules 2, Winged round pipe fixing part 3, lead pipe-coarse sand energy dissipation and shock absorption key 4 are composed of lead pipe-coarse sand energy dissipation and shock absorption key 4 by lead pipe 5, coarse sand 6, galvanized thin steel sheet cover plate 7 and Composed of 8 bolts.

[0042] in particular:

[0043] The recycled concrete wall panel 1 is composed of recycled concrete and a single row of reinforced steel wire mesh, wherein the diameter of the recycled concrete coarse aggregate particle is 5mm-10mm; the specification of the recycled concrete wall panel 1: the length is 600mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com