Heating device with adjustable area of heat transfer surface

A heating device and heat transfer surface technology, which is applied in the field of building windows, can solve the problems that cannot be adjusted according to needs, the area of the heat transfer surface is fixed, and the heating device is complicated, so as to achieve good load-bearing capacity, ensure temperature stability, and flexible use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

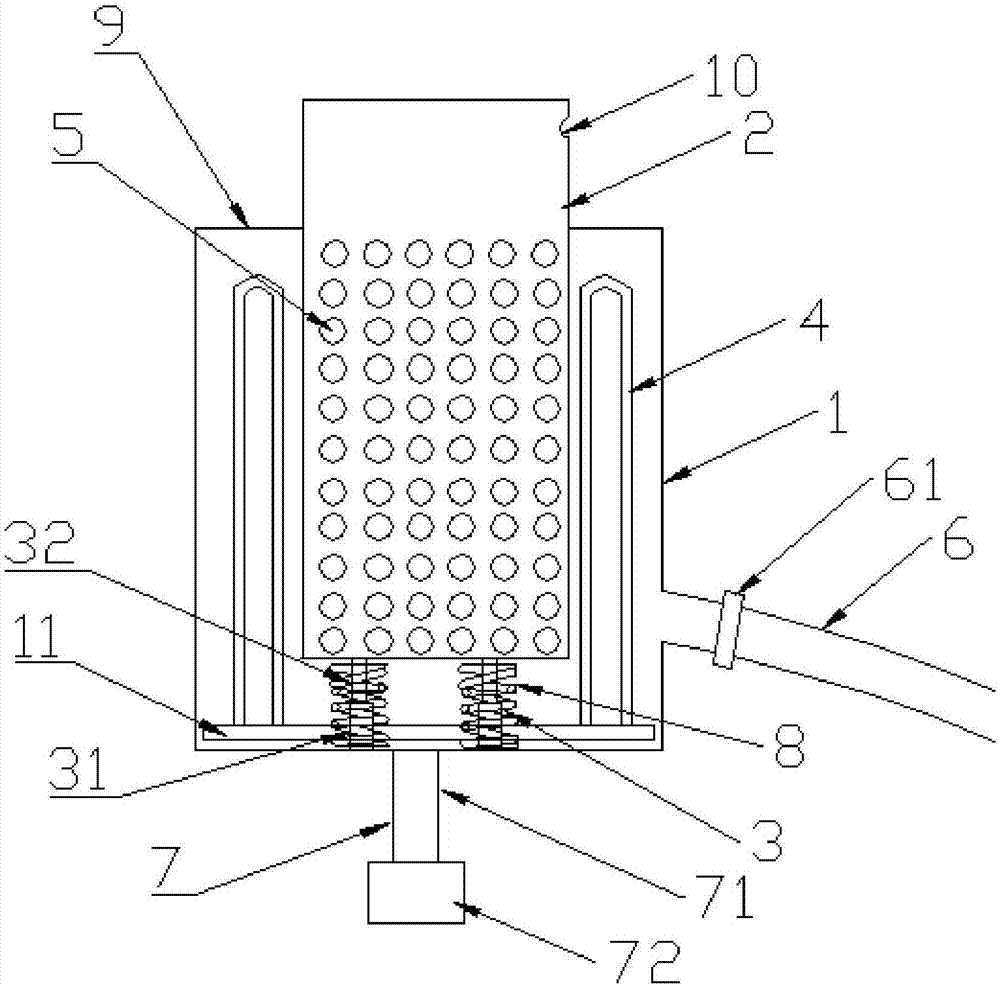

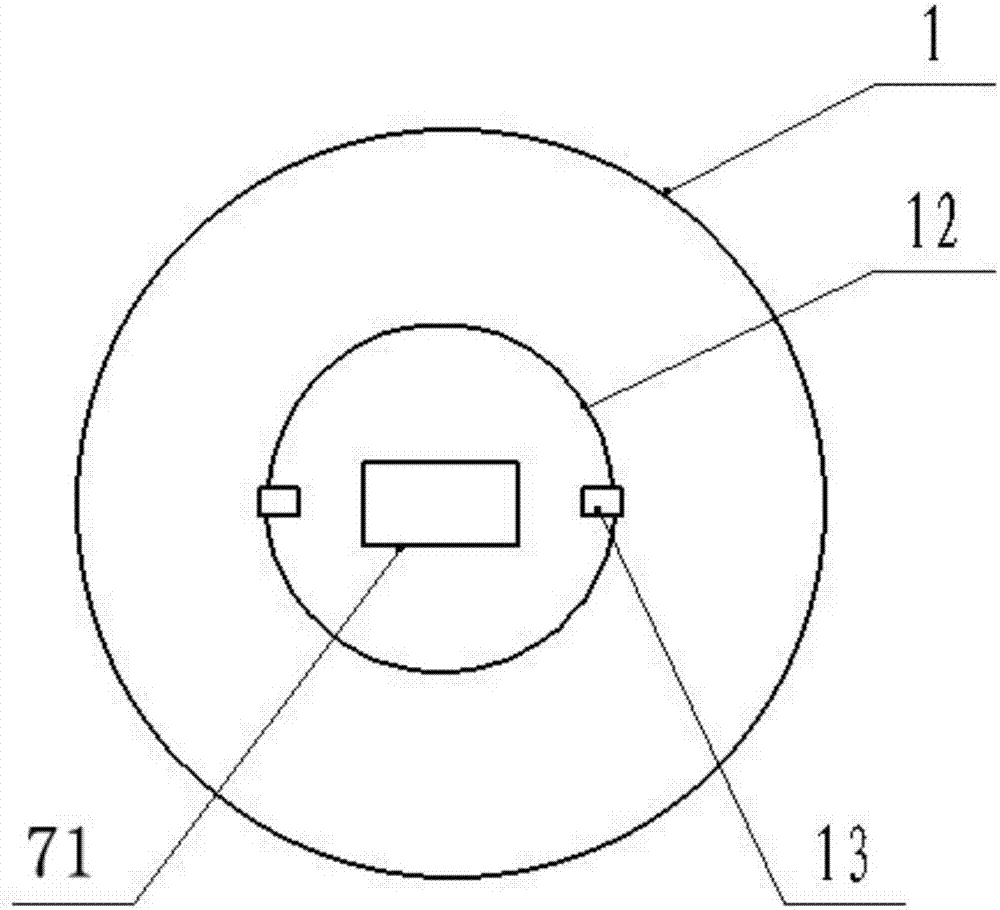

[0026] Such as figure 1 and figure 2 As shown, a heating device with an adjustable heat transfer surface area includes an outer barrel 1 and an inner barrel 2, and the inner barrel 2 is fixed in the outer barrel 1 through a telescopic rod 3. One end of the telescopic rod 3 is connected with the outer bottom of the inner barrel 2, and the other end is connected with the inner bottom of the outer barrel 1. The level of the upper end of the inner barrel 2 is higher than the level of the upper end of the outer barrel 1, and the telescopic length of the telescopic rod 3 is equal to the height of the part of the inner barrel 2 higher than the outer barrel 1. The telescopic rod 3 is also located on a movable support block 12, and is arranged at the lower end of the inner barrel 2 through the movable support block 12. In the present embodiment, the movable support block 12 is a cylinder, and the bottom of the outer barrel 1 is provided with an accommodating The round hole of the mo...

Embodiment 2

[0034] The present embodiment is the same as the embodiment 1 except that the parts by weight of the components of the insulation layer are different from the embodiment 1.

[0035] The insulation layer is mainly made of the following components by weight: 60 parts of calcium silicate powder, 30 parts of perlite, 10 parts of antimony trioxide, 10 parts of aluminum hydroxide, 20 parts of reinforcing glue, 20 parts of sodium peroxide, ten parts 2 parts of sodium dialkylsulfonate and 1 part of soluble silicone oil. Wherein, the reinforcing glue is formed by mixing silicon dioxide, wood fiber, polyvinyl alcohol and water in a weight ratio of 0.5:1.2:2.5:30.

Embodiment 3

[0037] The present embodiment is the same as the embodiment 1 except that the parts by weight of the components of the insulation layer are different from the embodiment 1.

[0038] The insulation layer is mainly made of the following components by weight: 55 parts of calcium silicate powder, 25 parts of perlite, 8 parts of antimony trioxide, 8 parts of aluminum hydroxide, 15 parts of reinforcing glue, 15 parts of sodium peroxide, ten parts 1 part of sodium dialkylsulfonate and 0.8 part of soluble silicone oil. Wherein, the reinforcing glue is formed by mixing silicon dioxide, wood fiber, polyvinyl alcohol and water in a weight ratio of 0.3:1.1:2.3:28.

[0039] The working principle of the present invention is: when the area of the heat transfer surface needs to be increased, the movable support block 12 is raised by the adjustment of the lifting regulator 71 in the lifting adjustment mechanism 7, and then the telescopic rod 3 is contracted, and the inner barrel 2 is lowered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com