Method for fault diagnosis of rotating machinery shaft crack

A fault diagnosis, rotating machinery technology, applied in computer parts, special data processing applications, instruments, etc., can solve problems such as verifying fault prediction and classification accuracy, and achieve the effect of reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

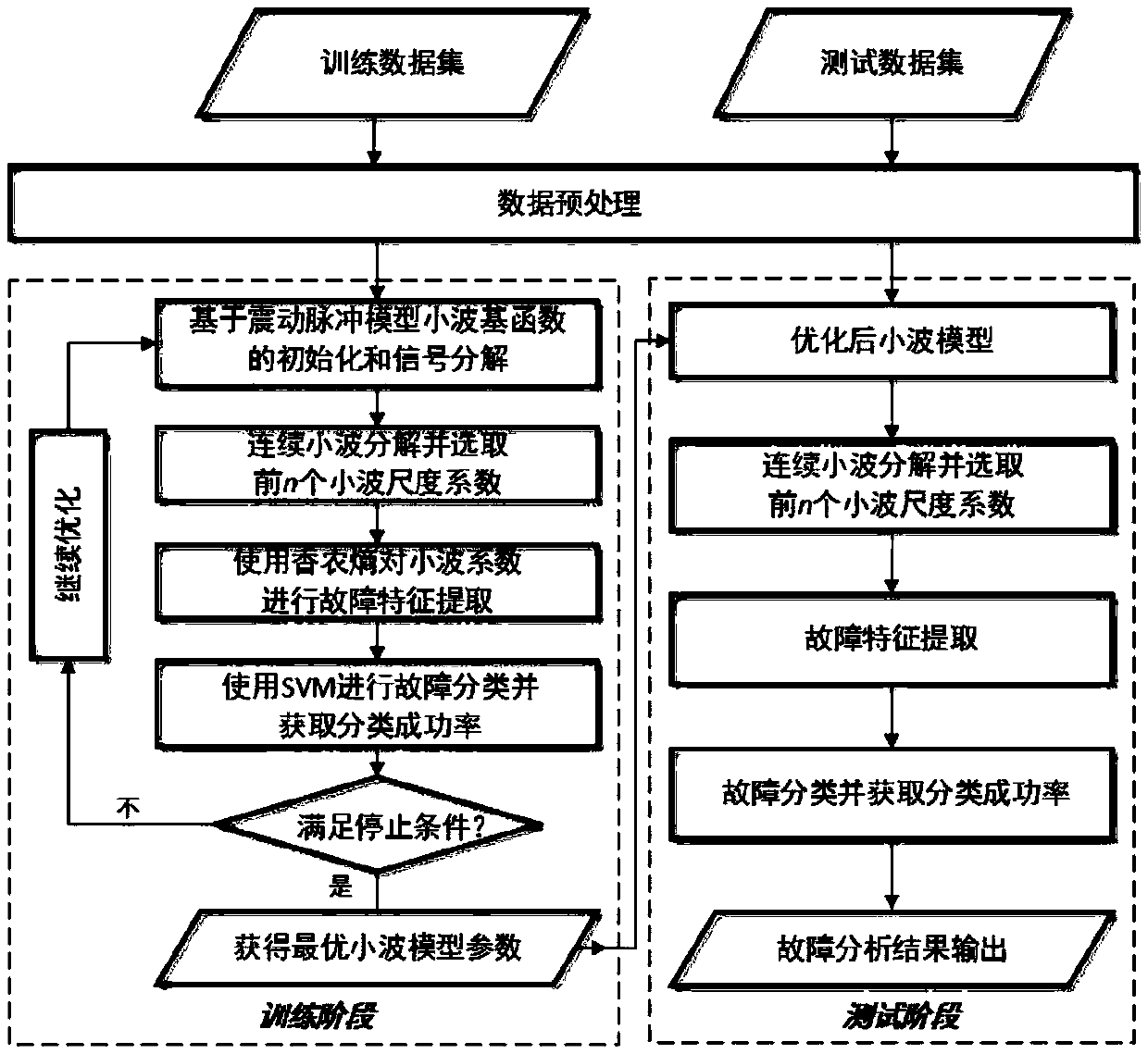

[0037] Such as figure 1 As shown, a method for diagnosing cracks in rotating machinery rotating shafts according to the present invention includes the following steps:

[0038] In step S1, the vibration signal of the rotating shaft is discretely sampled, and the vibration signal is preprocessed to eliminate data magnitude errors.

[0039]From the experimental results and literature reading, we know that the magnitude of the experimental data will have different effects on the experimental results. In the present invention, in order to eliminate the magnitude error caused by the data magnitude of the collected vibration signal and the influence on the experimental analysis results, before using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com