Display panel

A display panel and display area technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of AMOLED panel chipping, chipping and other problems, so as to reduce the risk of fragmentation, prolong the service life, and improve the anti-vibration strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

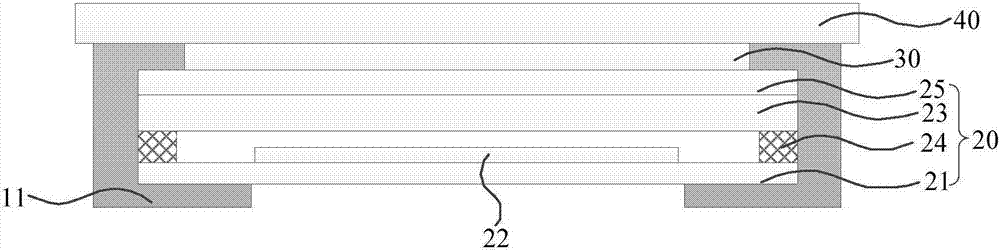

[0041] Please refer to figure 2 , the present embodiment provides a display panel, which includes: a display module 20 , a cover plate 40 , an adhesive layer 30 and a first buffer portion 11 .

[0042] The display module 20 includes an upper surface and a lower surface parallel to each other, and four sides. An organic electroluminescent display module or a liquid crystal display module may be used, and the present invention does not limit its type. This embodiment takes an organic electroluminescent display module as an example for illustration, which includes: a thin film transistor array substrate 21, a display unit 22 disposed on the thin film transistor array substrate 21, a packaging substrate 23 disposed on the display unit 22, and a The encapsulation material 24 is between the TFT array substrate 21 and the encapsulation substrate 23 and surrounds the display unit 22 , wherein the upward surface of the display module 20 along the encapsulation substrate 23 is a light-...

Embodiment 2

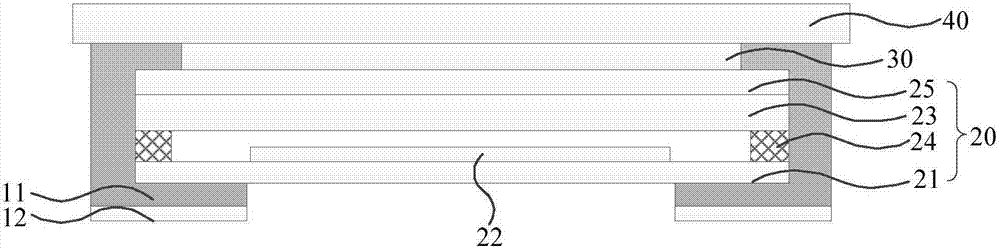

[0059] Please refer to Figure 3A , 3B and 3C, the difference between this embodiment and embodiment 1 is that the display panel further includes a second buffer portion 12 covering at least part of the first buffer portion 11 .

[0060] Existing electronic devices not only have different sizes, but also have different gaps between the display panel and the housing of the electronic device. The preset first buffer portion 11 may not be able to completely fill the gap. Part of the outer surface of the first buffer portion 11 is provided with a second buffer portion 12, which supplements and fills the gap, thereby enhancing the overall strength of the display panel and preventing the display panel from being damaged by impact when dropped.

[0061] like Figure 3A As shown, the surface of the first buffer portion 11 covered by the second buffer portion 12 is parallel to the lower surface of the display module 20, so as to fill the gap between the lower surface of the display m...

Embodiment 3

[0065] Please refer to Figure 4A , The difference between this embodiment and Embodiment 1 is that the display panel further includes a colloid 13 , and the colloid 13 is located between the first buffer portion 11 and the display module 20 . The glue 13 preferably covers at least the sides of the display module 20 , and the glue 13 may also cover part of the upper surface or part of the lower surface of the display module 20 . The side of the display module 20 is covered by the colloid 13 or together with the first buffer part 11, so that there is no gap at the edge of the display panel, and the display panel and the electronic equipment casing are integrated, effectively preventing the electronic equipment from falling or dropping. When impacting the display panel, the risk of fragmentation is reduced, and during the panel cutting process, the colloid 13 can avoid micro-cracks on the side of the display panel, reducing the risk of fragmentation.

[0066] The glue 13 filled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com