Industrial machinery-based electric cabinet heat exchanger

A technology for heat exchangers and industrial machinery, applied in electrical components, substation/switch arrangement details, cooling/ventilation of substation/switchgear, etc., can solve the problem that the heat of the heat exchanger cannot be dissipated in time, and the parts in the heat exchanger are damaged , Reduce heat dissipation efficiency and other issues, achieve good heat dissipation effect, ensure stability, and good protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

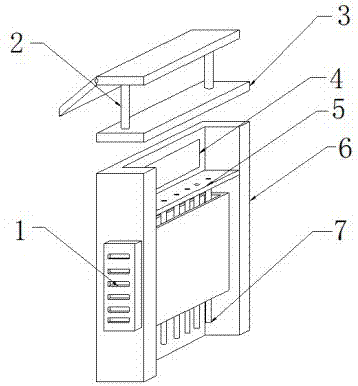

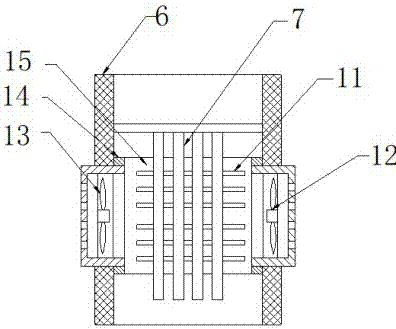

[0025] Specific implementation method: when in use, the ventilation pipe 7 transports the hot air in the electric cabinet to the casing 6, and then runs the upper heat dissipation fan 4, and the upper cooling fan 4 discharges the hot air in the ventilation pipe 7 out of the casing 6, and at the same time, the operator runs Exhaust fan 12 and intake fan 13, the heat collecting copper sheet 11 in the support seat 14 absorbs the heat on the vent pipe 7, and the intake fan 13 transports the cold air from the outside into the cavity body 15, and the heat collecting copper sheet 11 The heat is taken away, and the exhaust fan 12 discharges the air in the cavity body 15 to form air convection, thereby realizing the convection heat dissipation function and improving the rapid dissipation of residual heat in the present invention.

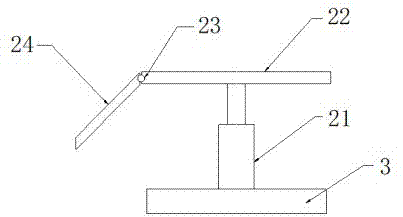

[0026] The operator operates the telescopic rod 21, so that the telescopic rod 21 is stretched to a suitable height, and the sun visor 22 blocks the ultravio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com