Footwear production line and shoemaking technology thereof

A production line and footwear technology, which is applied in the field of footwear manufacturing, can solve the problems of slow delivery speed, easy pollution of the environment, and cumbersome production process, and achieve the effects of reduced floor space, less process flow, and equipment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

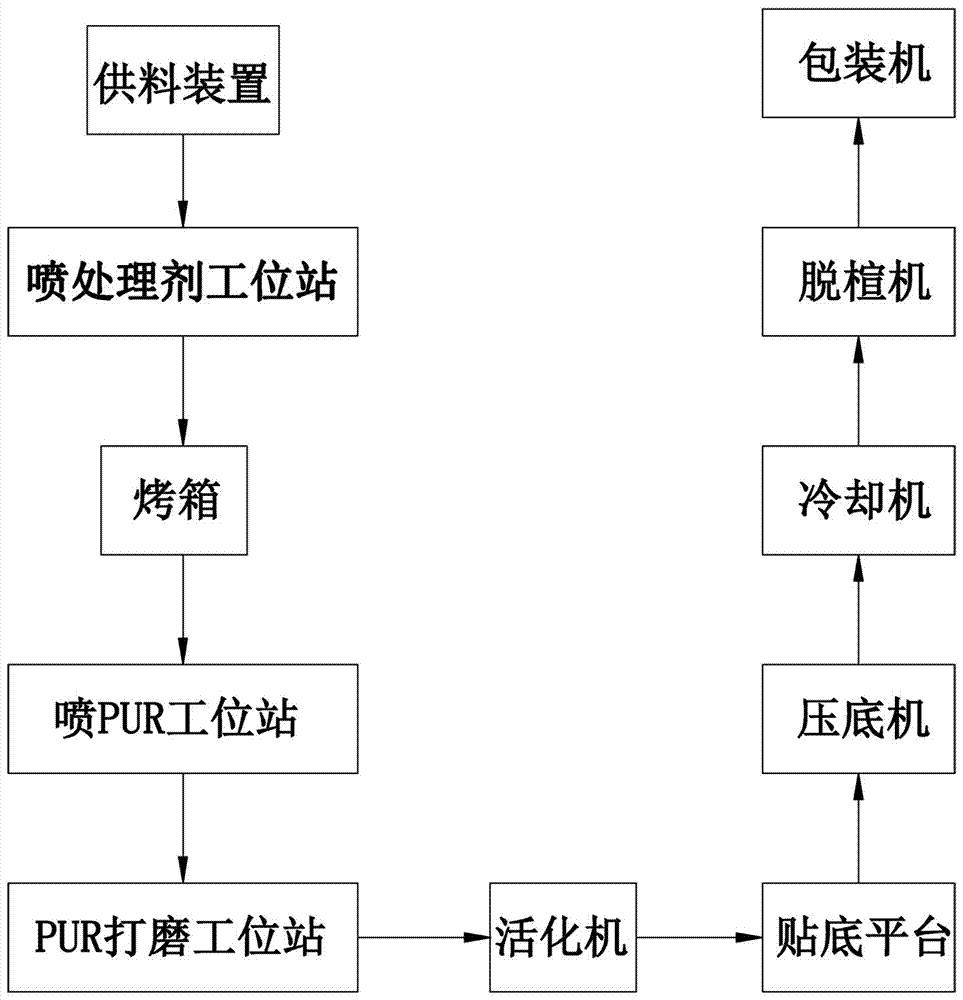

[0014] refer to figure 1 , a footwear production line and its shoemaking process, the shoe sole lamination production line includes a feeding device, a treatment agent station, an oven, a PUR spray station, a PUR polishing station, an activation machine, and a paste station connected in sequence. Bottom stations, bottom presses, freezers, last strippers and packaging machines.

[0015] The shoemaking process using the above-mentioned footwear production line includes the following steps:

[0016] The outsoles are supplied to the production line one by one by the above-mentioned feeding device, and the treatment agent is sprayed on the surface of the outsoles by the above-mentioned treatment agent station, and then dried by the above-mentioned oven.

[0017] (1) The above-mentioned PUR spraying station sprays PUR hot melt adhesive to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com