Semi-automatic spraying device with recycling function

A spraying device, semi-automatic technology, applied in the direction of spraying device, device for coating liquid on the surface, coating, etc., can solve the problems of paint waste, air pollution, energy saving and environmental protection, etc., to reduce production costs and prevent air pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

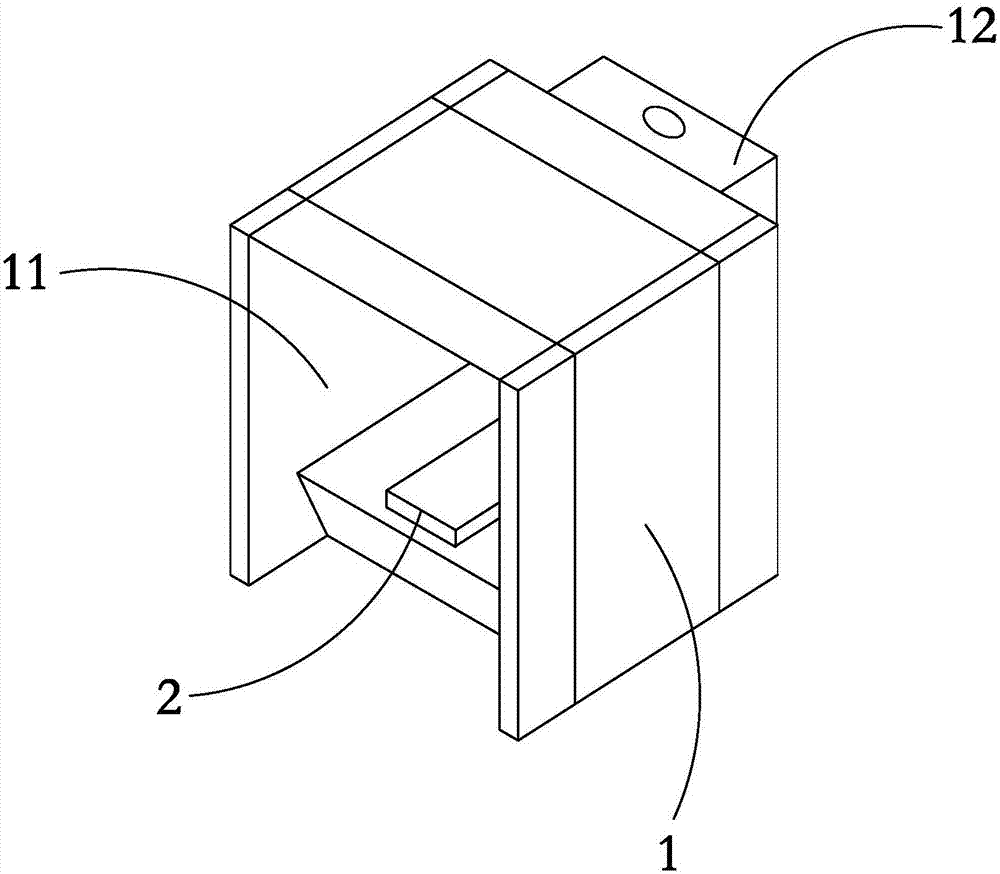

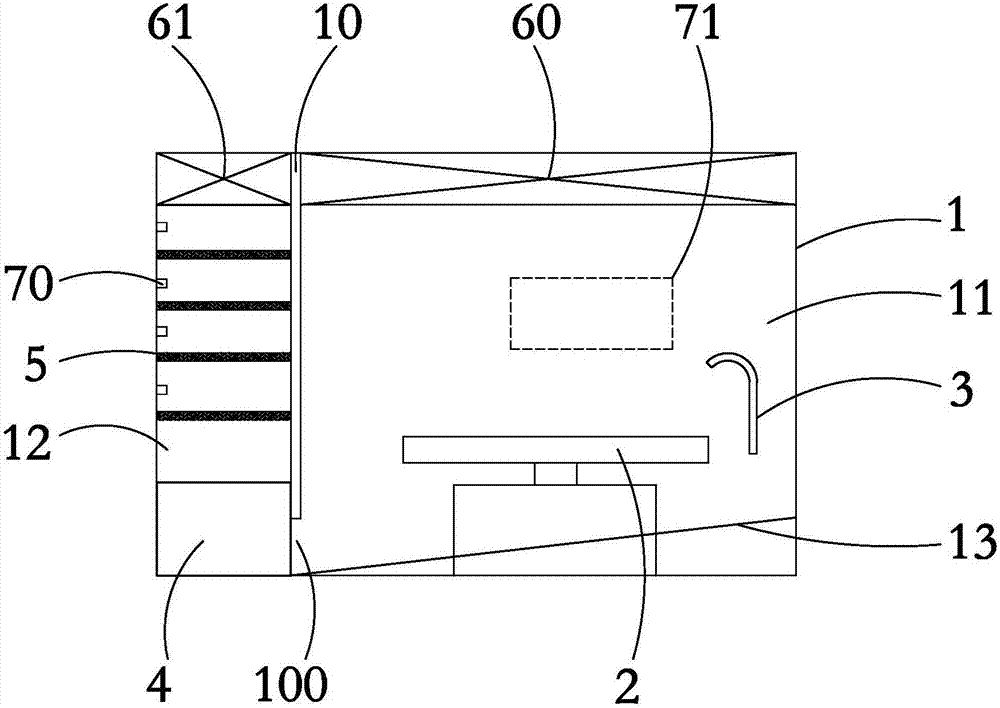

[0034] like figure 1 , 2 A semi-automatic recovery and spraying device shown mainly includes a housing 1, an automatic spraying platform 2, a spraying system, a recovery system, a purification system, a wind pressure system and an intelligent monitoring system. Wherein: the automatic spraying platform 2 , the recovery system, the purification system and the air pressure system are all arranged in the casing 1 . The following is a detailed introduction to each system:

[0035] The housing 1 is made of metal, and the front of the housing 1 is open for manual placement of products and operation of the spraying system. A partition 10 is provided inside the casing 1, and the partition 10 divides the casing 1 into a spraying area 11 and a recovery purification area 12. The top of the recovery purification area 12 communicates with the outside, and the spraying a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com