Drawing type steel inner die and construction method of prefabricated hollow slab girder

A hollow slab beam and pull-type technology, which is applied in the direction of manufacturing tools, ceramic molding mandrels, ceramic molding machines, etc., can solve the problem of ensuring that the pulling force coincides with the axis of the pull rod, reducing the utilization rate of the steel inner mold and production efficiency, steel Problems such as internal mold sticking have been solved, and the drawing operation is stable and controllable, the construction efficiency is high, and the effect of easy demoulding is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

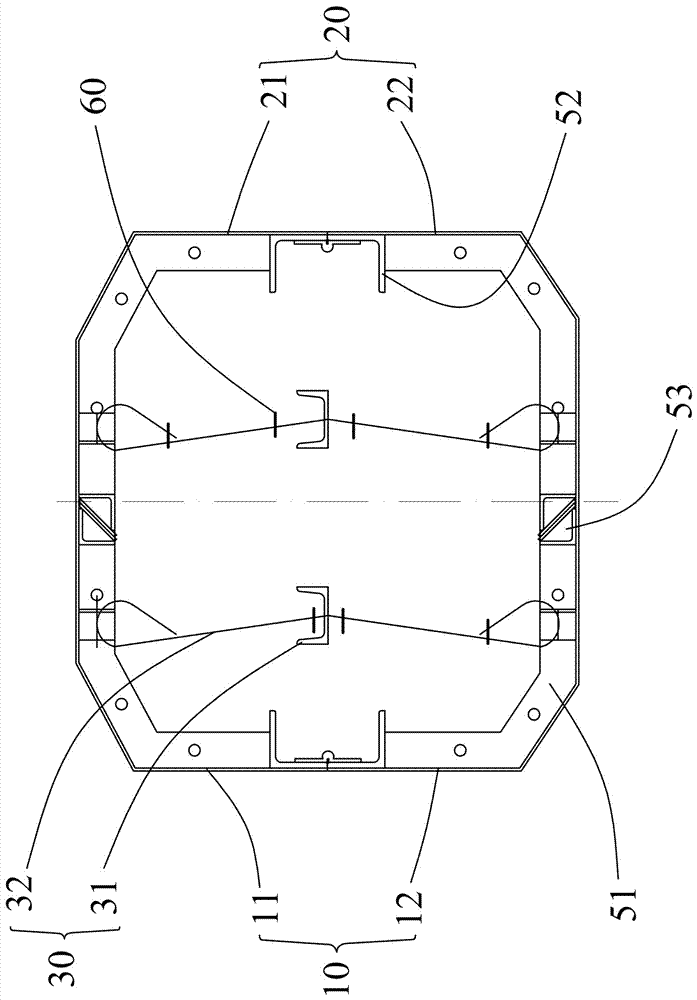

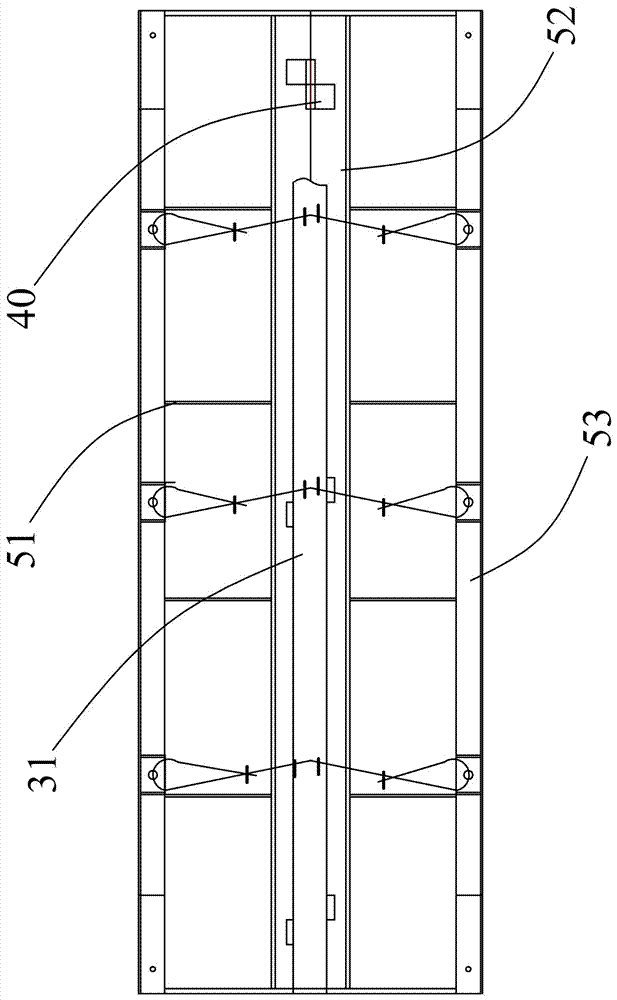

[0058] This embodiment is the embodiment of the pull-out steel inner mold. See Figure 1 to Figure 2 , the length of each section of the pull-type steel inner mold in this embodiment is 5m, and each section of the steel inner mold includes a first formwork 10 and a second formwork 20. The first template 10 includes a first member 11 and a second member 12 that are vertically symmetrical, and the second template 20 includes a third member 21 and a fourth member 22 that are vertically symmetrical. The cross sections of the first member 11, the second member 12, the third member 21 and the fourth member 22 are all approximately L-shaped steel plates, and the four members together form a hollow cylindrical structure to form the outer frame of the pull-out steel inner mold body.

[0059] In this embodiment, each component is provided with a supporting steel plate 51 and a component beam 52 . Among them, the supporting steel plate 51 adopts a steel plate with a thickness of 1 cm,...

Embodiment 2

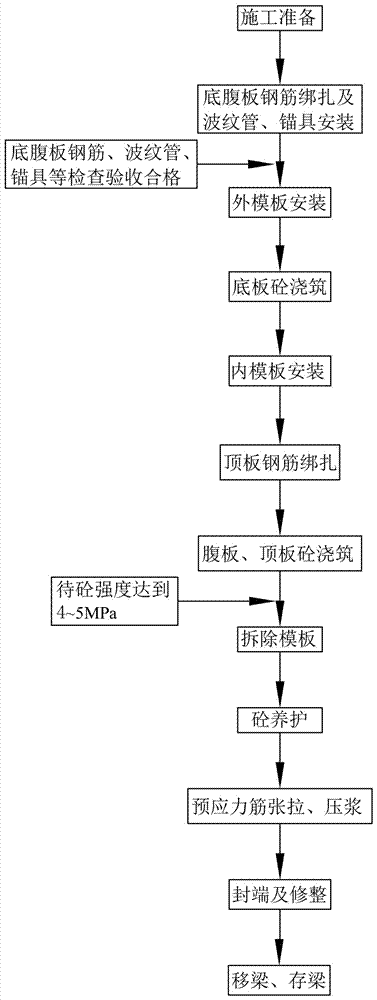

[0063] This embodiment is a construction method for realizing prefabricated hollow slab girders using the pull-out steel inner formwork of Embodiment 1. The process flow chart of the construction method of this embodiment can be found in image 3 , including the following steps:

[0064] Step 1: Construction preparation. Construction preparation mainly includes site selection, prefabricated pedestal, steel formwork processing; reinforcement and concrete material acceptance and storage; mixing and transportation equipment and other tools; Example 1 of the pull-type steel inner mold.

[0065] Step 2: Binding of bottom and web steel bars and installation of bellows and anchors. This step includes the following sub-steps. The order of the sub-steps is not specified, and they are strictly carried out in accordance with the design drawings and construction technical specifications:

[0066] Step 2.1: Bottom and web reinforcement binding. On the prefabricated pedestal, the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com