Elastic sound-absorbing PVC (Polyvinyl Chloride) floor and preparation method thereof

A PVC resin, elastic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

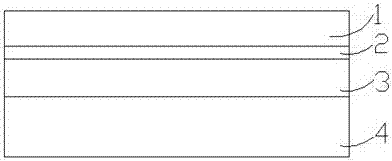

[0032] Such as figure 1 As shown, an elastic sound-absorbing PVC floor, from top to bottom is an elastic PVC transparent layer 1 , a printed fabric layer 2 , a base material layer 3 , and an elastic sound-absorbing layer 4 .

[0033] Wherein, the elastic PVC transparent layer is made of the following raw materials in mass ratio: 100 parts of highly polymerized PVC resin, 100 parts of plasticizer, 2 parts of calcium zinc stabilizer, and 0.5 part of anti-UV agent.

[0034] The substrate layer is made of the following raw materials in mass ratio: 100 parts of PVC resin (SG-5), 30 parts of plasticizer, 2 parts of calcium zinc stabilizer, 250 parts of calcium carbonate, and 1 part of pigment.

[0035] The elastic sound-absorbing layer can be a non-foaming high-elasticity PVC bottom film, or a foaming high-elasticity PVC bottom film. The non-foaming high elastic PVC base film is made of the following raw materials in mass ratio: 100 parts of highly polymerized PVC resin, 70 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com