Sodium borohydride alcoholysis hydrogen production device with bidirectional spraying feeding

A technology of sodium borohydride alcohol and sodium borohydride, applied in the field of sodium borohydride hydrogen production equipment, can solve the problems of increasing the difficulty of controllable hydrogen production, incomplete hydrogen production reaction, discontinuous hydrogen production, etc., and achieve accurate hydrogen production Controllable, complete response, and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

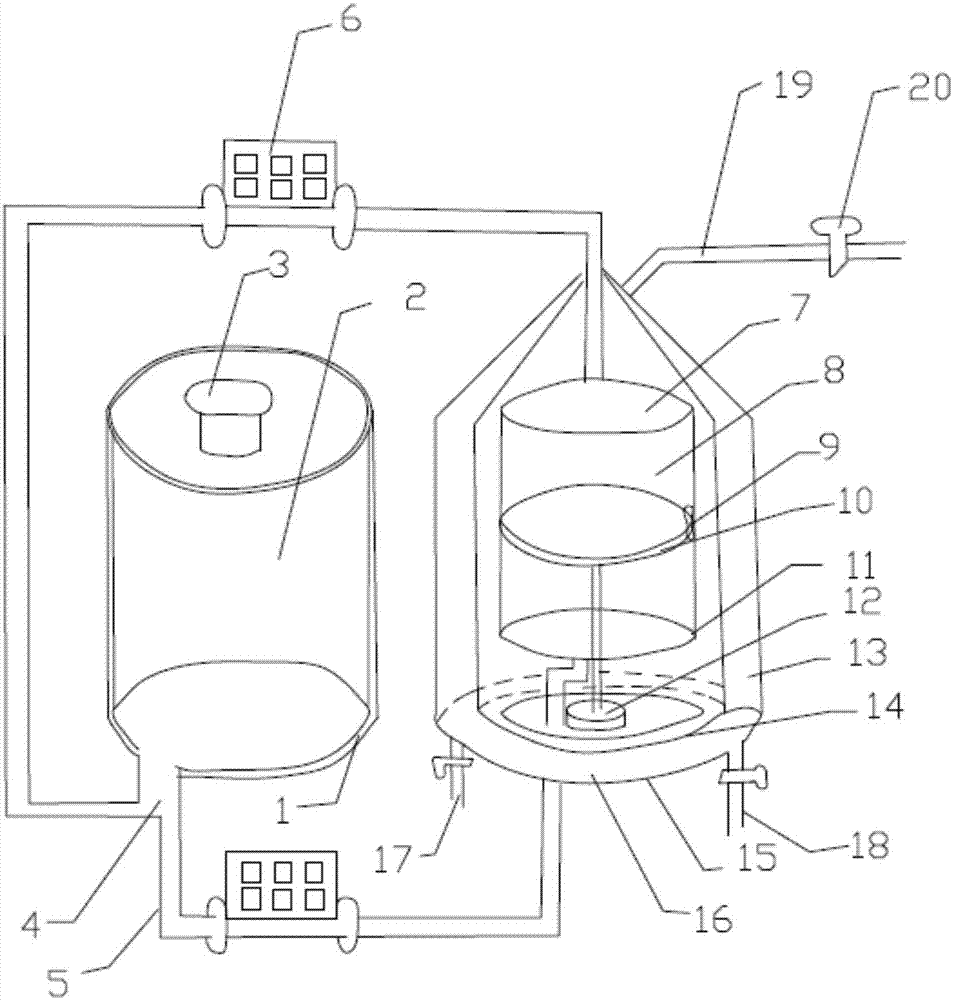

[0040] see figure 1 , the present invention discloses a sodium borohydride alcoholysis hydrogen production device with two-way spray feeding, mainly comprising a sodium borohydride liquid storage tank (sodium borohydride methanol solution liquid storage tank) 1, a flow controller 7 (11), Sprayer (atomizer) 10, catalyst reaction bed, heat exchanger, product recovery tank 13.

[0041] The sodium borohydride storage tank 1 is used to store alkaline sodium borohydride methanol solution (alkaline sodium borohydride methanol solution 2), and the sodium hydroxide solution is mixed with the sodium borohydride methanol solution to suppress the autoalcoholysis reaction. The storage device has good heat insulation from the external environment, which prevents the sodium borohydride methanol solution from producing hydrogen due to alcoholysis due to the increase in the external environment temperature, resulting in high pressure in the liquid storage tank. The liquid storage tank is equi...

Embodiment 2

[0048] figure 1 The sodium borohydride alcoholysis hydrogen production device based on two-way spray feeding is composed of sodium borohydride liquid storage tank, flow controller, upper and lower sprayers, catalyst reaction bed, heat exchanger, product recovery tank and other parts. The catalyst reaction bed is a foamed nickel-supported Ru catalyst, with a catalyst load of 2g, using a methanol solution containing 5wt.% sodium borohydride and 3wt.% sodium hydroxide as the reactant, and produces hydrogen when it reaches a steady state at 50°C The flow rate is 2.8 L / min.

Embodiment 3

[0050] figure 1 The sodium borohydride alcoholysis hydrogen production device based on two-way spray feeding is composed of sodium borohydride liquid storage tank, flow controller, upper and lower sprayers, catalyst reaction bed, heat exchanger, product recovery tank and other parts. The catalyst reaction bed is a carbon cloth supported CoB catalyst, using a methanol solution containing 5wt.% sodium borohydride and 3wt.% sodium hydroxide as the reactant, and the catalyst loading is 2g. Under the condition of 0°C, hydrogen is produced when it reaches a steady state The flow rate is 1.2 L / min.

[0051] In summary, the two-way spray feed sodium borohydride alcoholysis hydrogen production device proposed by the present invention uses a flow controller to accurately control the quality and flow rate of the reactants, improve the utilization of the reactants, and achieve accurate hydrogen production. Controllable; spraying, top-down and bottom-up, or two-way feeding methods expand ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap