Foamed concrete light material and construction method for filling traditional rowlock wall

A foamed concrete, lightweight material technology, applied in walls, building components, applications, etc., can solve problems such as limiting the wide application of empty bucket walls, improve firmness and stability, increase bearing capacity, and improve fire performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

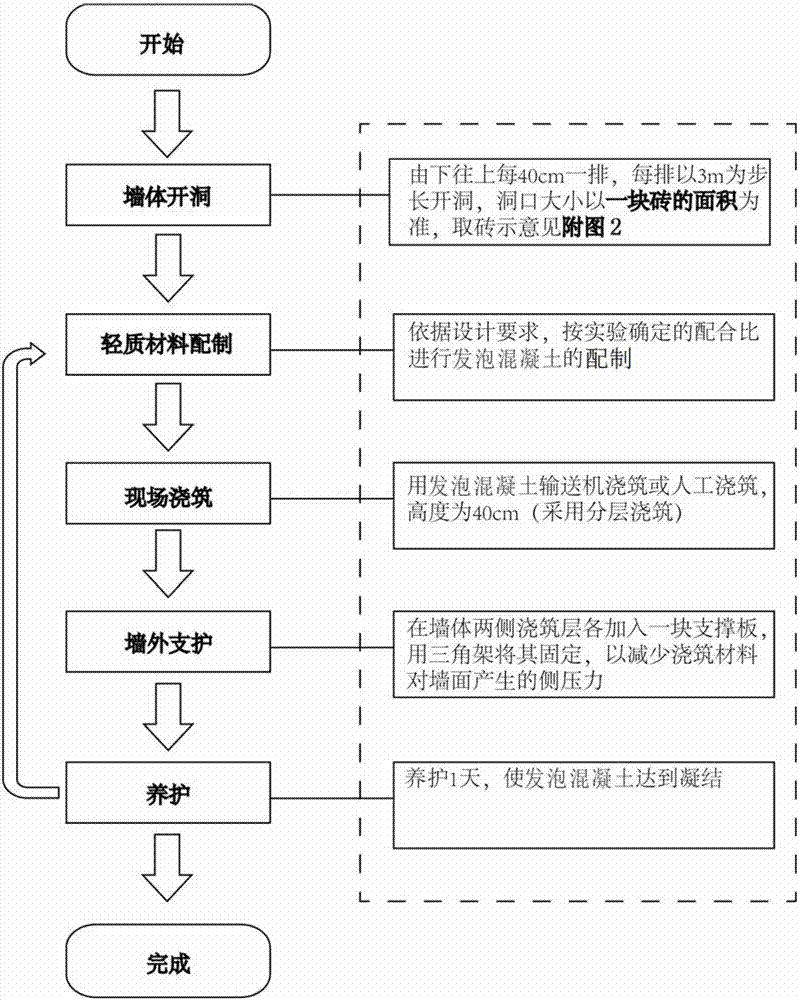

[0047] see image 3 As shown, a construction method of using foamed concrete lightweight material to fill the traditional empty bucket wall, the steps are as follows:

[0048] ① Hole in the wall

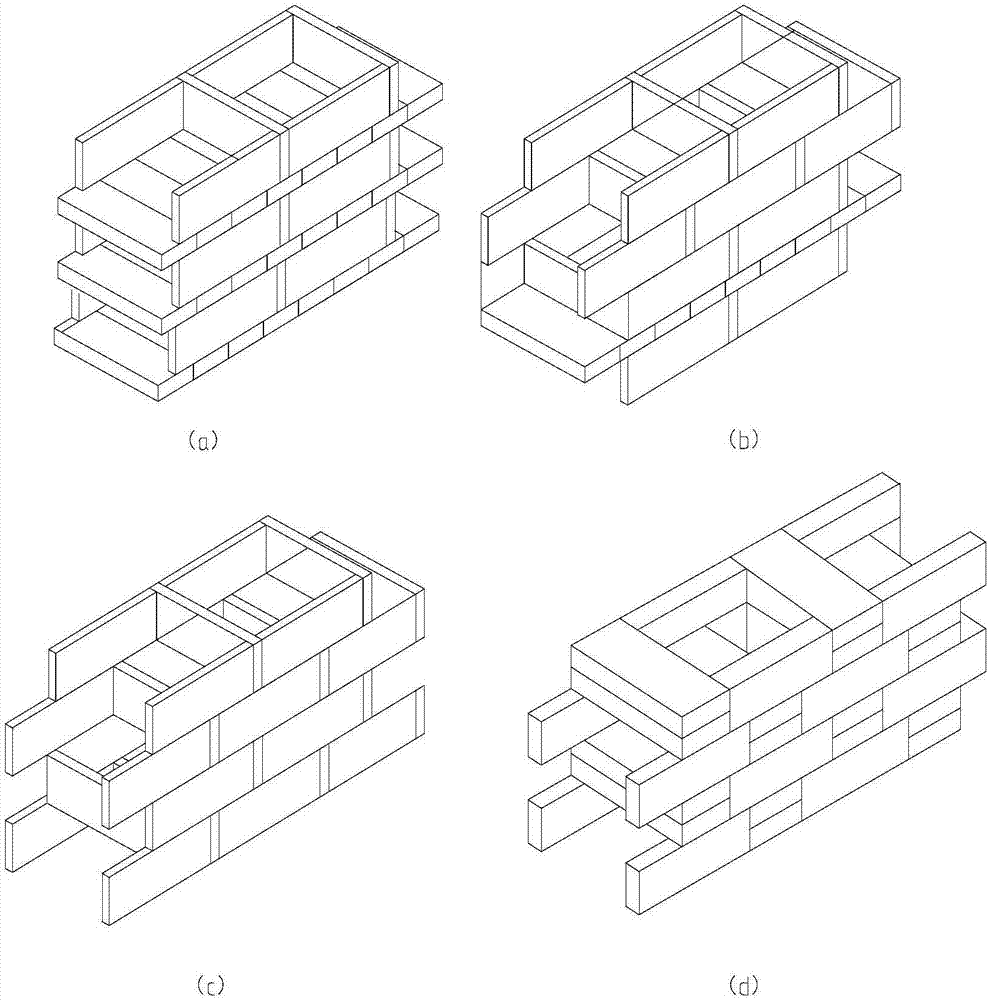

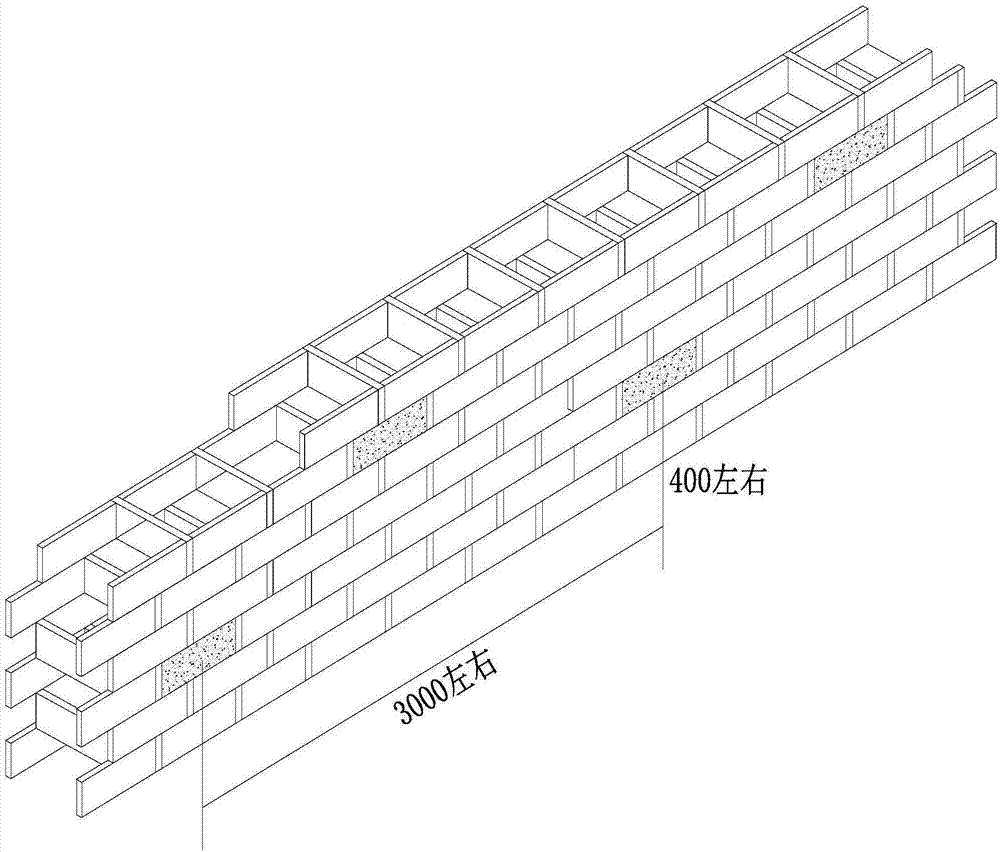

[0049] see figure 2 As shown, taking the empty bucket wall of the full-bucket sleepless masonry method as an example, a row of bricks is taken every 40cm from bottom to top on the wall, and each row takes 3m as a step to open holes. The horizontal distance between adjacent holes in the direction is 1.5m.

[0050] ②, preparation of foamed concrete lightweight material

[0051] a. Preparation of construction materials

[0052] (1) Cement: The amount used for a single preparation is 20kg, and the general-purpose Portland cement with a strength grade of 42.5 should be used, which should meet the requirements of "General-purpose Portland Cement" GB175-2007.

[0053] (2) Foaming agent: The amount used in a single preparation for construction is 4kg (after dilution), and a foaming age...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap