Concrete anchoring agent

An anchoring agent and concrete technology, which is applied in the field of concrete additives, can solve the problems of uneven product quality, affect the bonding performance, and loose concrete, and achieve the effects of facilitating on-site construction, improving porosity, and increasing compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

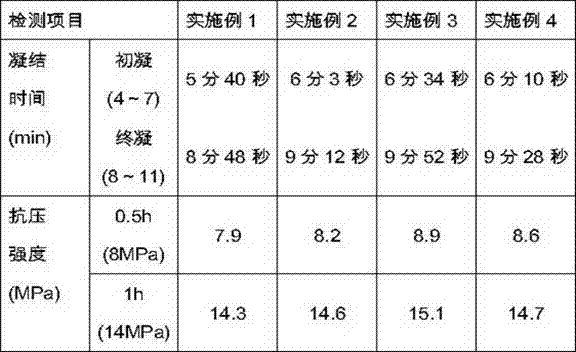

Examples

Embodiment 1

[0014] A concrete anchoring agent, the anchoring agent is composed of the following components in parts by weight: 75 parts of cement, 25 parts of coarse stone powder, 60 parts of fine stone powder, 20 parts of fine fly ash, 15 parts of clay, 10 parts of glass beads, wood 10 parts of sodium sulfonate and 8 parts of anhydrous sodium sulfate. Wherein the coarse stone powder is quartz sand with a particle size of 30-40 mesh; the fine stone powder is quartz fine sand with a particle size of 120-130 mesh; the particle size of the fine fly ash is 80-90 mesh ; Described cement is the portland cement of label 42.5.

Embodiment 2

[0016] A concrete anchoring agent, the anchoring agent is composed of the following components in parts by weight: 80 parts of cement, 30 parts of coarse stone powder, 65 parts of fine stone powder, 25 parts of fine fly ash, 20 parts of clay, 15 parts of glass beads, wood 13 parts of sodium sulfonate and 10 parts of anhydrous sodium sulfate. Wherein the coarse stone powder is quartz sand with a particle size of 30-40 mesh; the fine stone powder is quartz fine sand with a particle size of 120-130 mesh; the particle size of the fine fly ash is 80-90 mesh ; Described cement is the portland cement of label 42.5.

Embodiment 3

[0018] A concrete anchoring agent, the anchoring agent is composed of the following components in parts by weight: 85 parts of cement, 35 parts of coarse stone powder, 70 parts of fine stone powder, 30 parts of fine fly ash, 25 parts of clay, 20 parts of glass beads, wood 15 parts of sodium sulfonate and 12 parts of anhydrous sodium sulfate. Wherein the coarse stone powder is quartz sand with a particle size of 40-50 mesh; the fine stone powder is quartz fine sand with a particle size of 130-150 mesh; the particle size of the fine fly ash is 90-100 mesh ; Described cement is the portland cement of label 42.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com