Adjustable and automatic control system for grey cloth burr trimming and method

An automatic control system and adjustable technology, which is applied in the fields of seam trimming, textile and papermaking, textile material cutting, etc., can solve the problems of uneven trimming edges, waste of resources, low efficiency, etc., to improve trimming accuracy, Effect of reducing trim waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

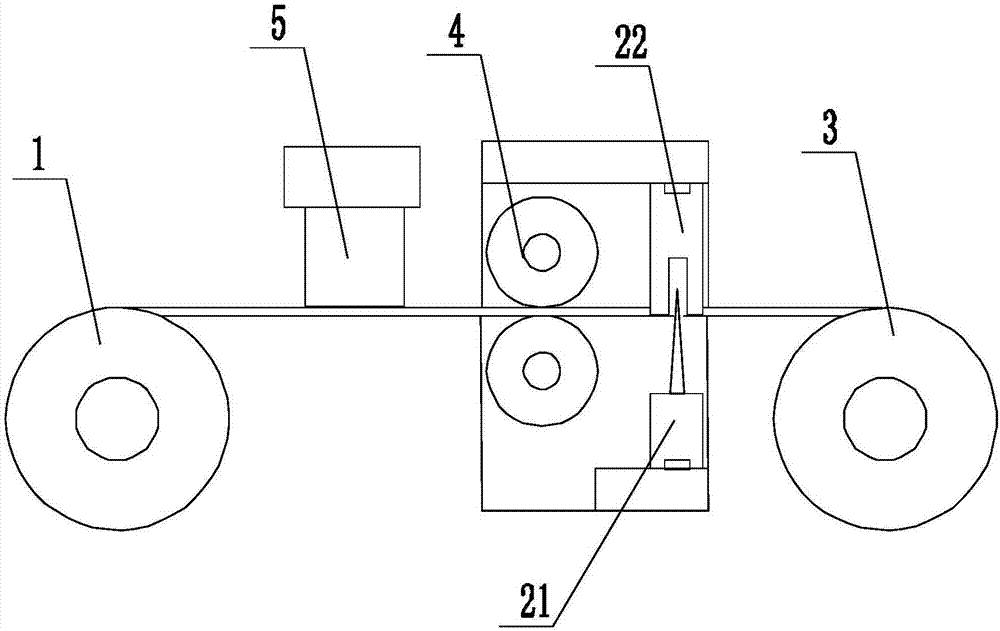

[0025] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an automatic control system for adjustable gray cloth trimming proposed by the present invention.

[0026] The present invention proposes an automatic control method for adjusting gray cloth rough edges, which includes the following steps: feeding, flattening, testing, trimming, and winding;

[0027] S1. Feeding: use the feeding device 1 to send out the rolled gray cloth;

[0028] S2, flattening: using the wrinkle removing device 5 to flatten the greige cloth sent out by the feeding device 1;

[0029] S3. Detection: using a detection device to detect the position of the burr on the edge of the flattened gray cloth, specifically for detecting the edge position and width of the burr of the gray cloth;

[0030] S4. Trimming: use a trimming device to trim the burrs on the edge of the gray cloth;

[0031] S5. Rolling: use the rolling device 3 to roll the trimmed gray cloth.

[0032] Combined in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com