Coal seam hard top plate fracturing weakening method

A hard roof, cracking technology, used in earth-moving drilling, discharging machinery, ground mining and other directions, can solve the problems of coal and rock mass stress disturbance, failure to reach, pollution, etc., to speed up the crack propagation rate, and the construction is simple and convenient. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the accompanying drawings.

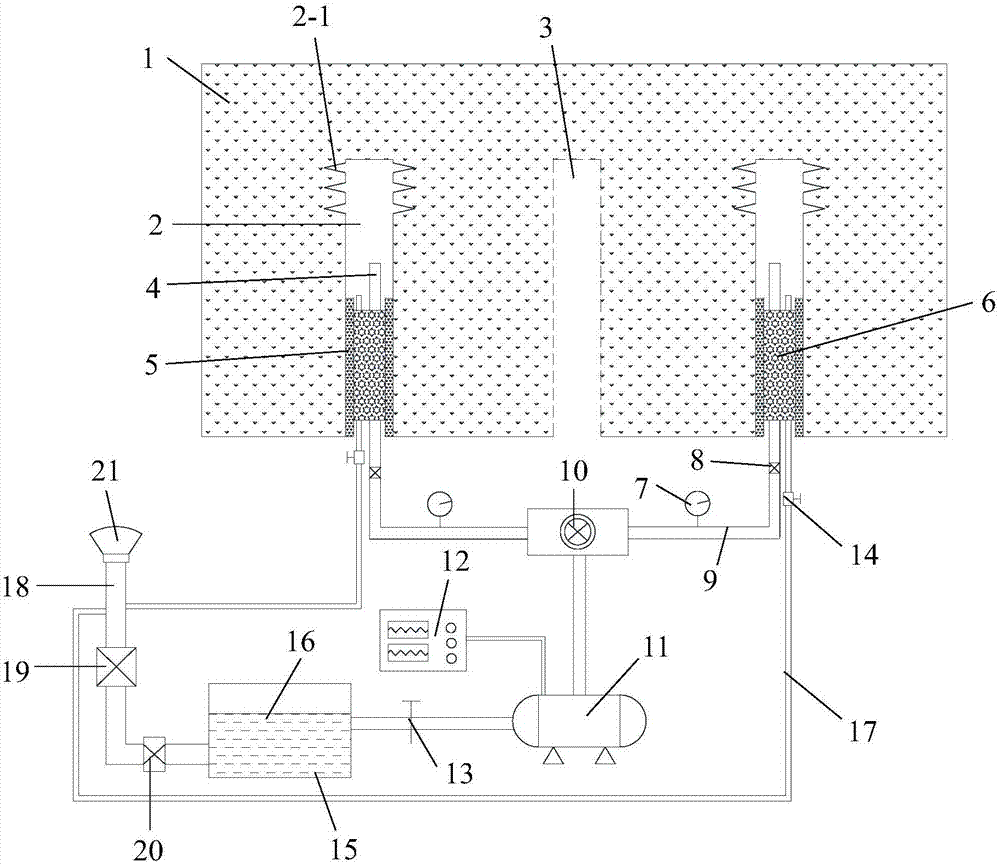

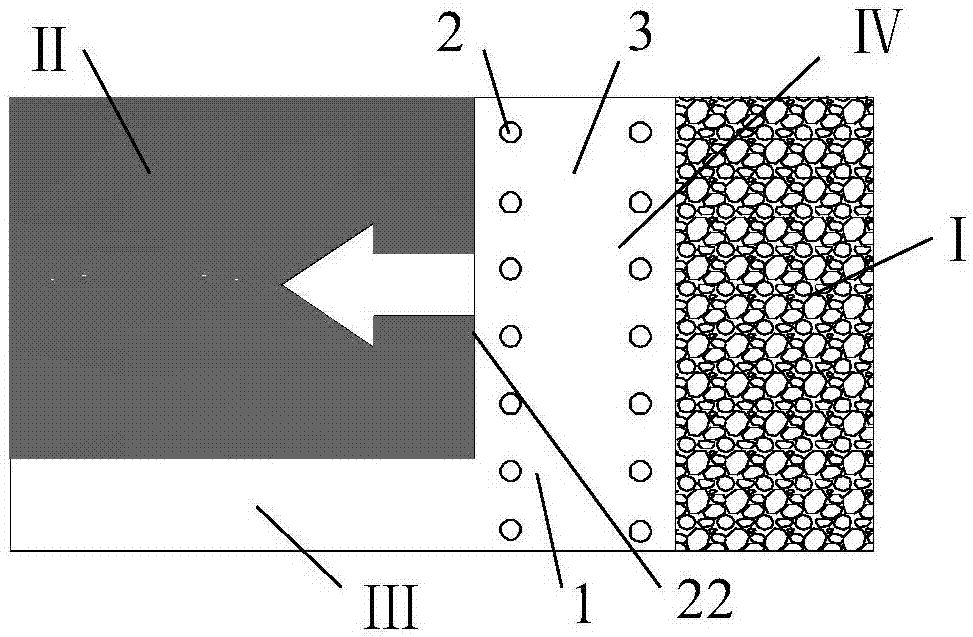

[0027] Such as figure 1 and 2 Shown, a kind of coal seam hard roof cracking weakening method of the present invention comprises the following steps:

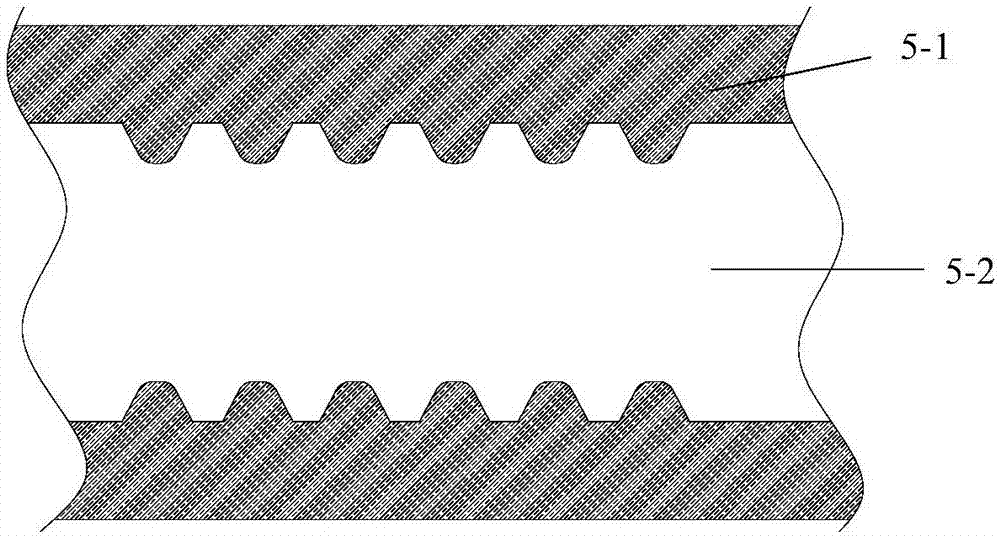

[0028] a. Drilling: When the mining face 22 moves forward for a certain distance, use a drilling rig to drill a plurality of cracking holes 2 and pilot holes 3 inside the hard roof stratum 1 in the stope area, and drill holes 2 and pilot holes 3 Spaced apart from each other, a wedge-shaped slot 2-1 is cut out at the top of the fracturing hole 2 using a hydraulic slotting device;

[0029] b. Preparation of liquid nitrogen: connect the air compressor 21 to the cooling unit 20 through the air extraction pipeline 18, install a negative pressure fan 19 on the air extraction pipeline 18, compress the air through the air compressor 21, and pass the compressed air through the cooling unit 20 cooling and liquefaction, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com