Test method used for corrosive wear

A test method, corrosion and wear technology, applied in the field of mobile communications, can solve problems such as low signal-to-noise ratio, difficult steady state of corrosive media, difficult to achieve steady state, etc., and achieve reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

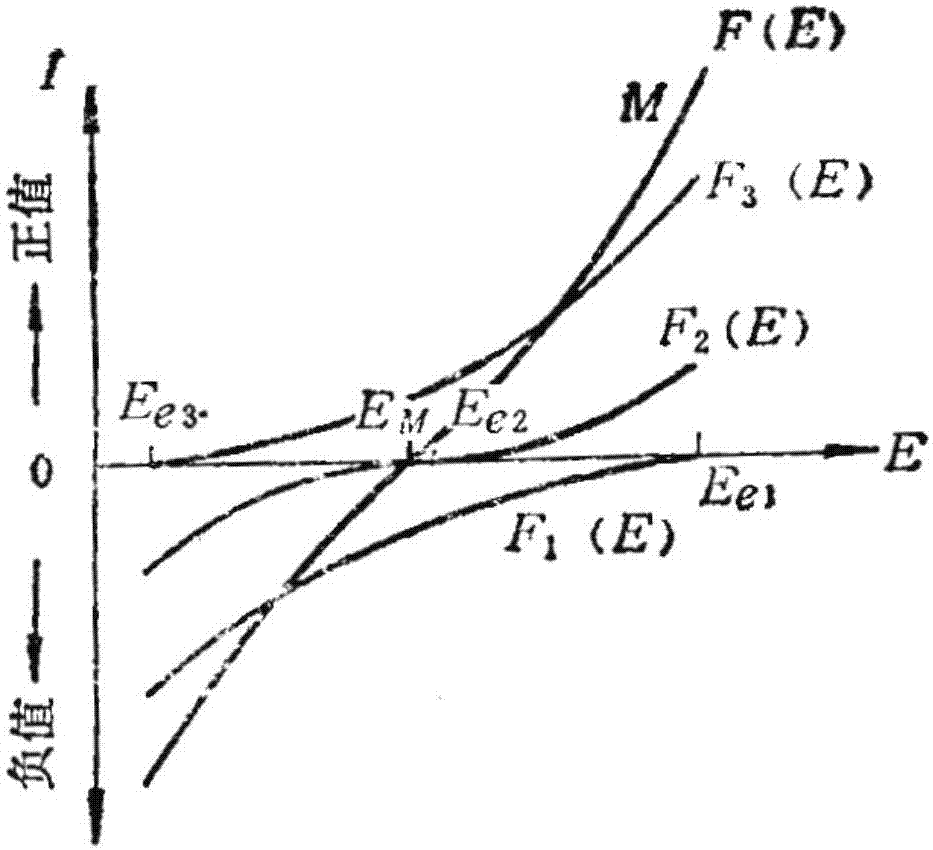

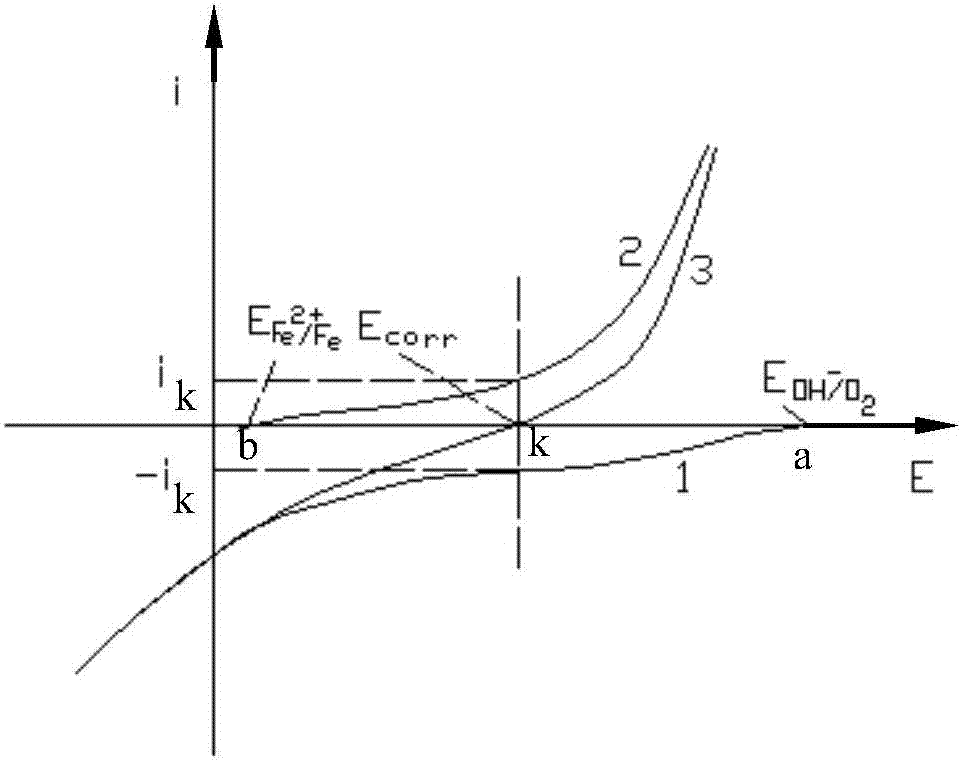

[0023] Because the process of measuring the local anodic reaction polarization curve of a corrosion electrode in an oxygen-removing medium is relatively complicated, the process of measuring the local cathodic reaction polarization curve of an inert electrode is relatively simple. Therefore, this embodiment adopts the method of combining the local cathodic reaction polarization curve of the inert electrode and the self-corrosion potential Ecorr of the corroded electrode to obtain the corrosion current density ik, which solves the problem that the corrosion test method requires high precision of the machine and can only be static The state of the measurement.

[0024] There are three traditional techniques for measuring corrosion rate electrochemically: linear polarization method, Tafal linear extrapolation method or weak polarization region fitting method, which are obtained by measuring the polarization curve and analyzing the values near the self-corrosion potential in the ...

Embodiment 2

[0039] Table 1 shows the weight loss of medium chromium steel under static immersion corrosion in 1molHCl / L aqueous solution at room temperature. Soak corrosion for 24 hours.

[0040] Table 1. Corrosion weight loss of medium chromium steel in static immersion in 1molHCl / L aqueous solution at room temperature

[0041]

[0042] The weight loss rate of pure impact wear is calculated by formula (1).

[0043]

[0044] Where: ΔE is the pure impact wear loss of the material (unit: g),

[0045] m is the outer cylindrical surface area of the sample (unit: m 2 ),

[0046] t is the test time h (hours).

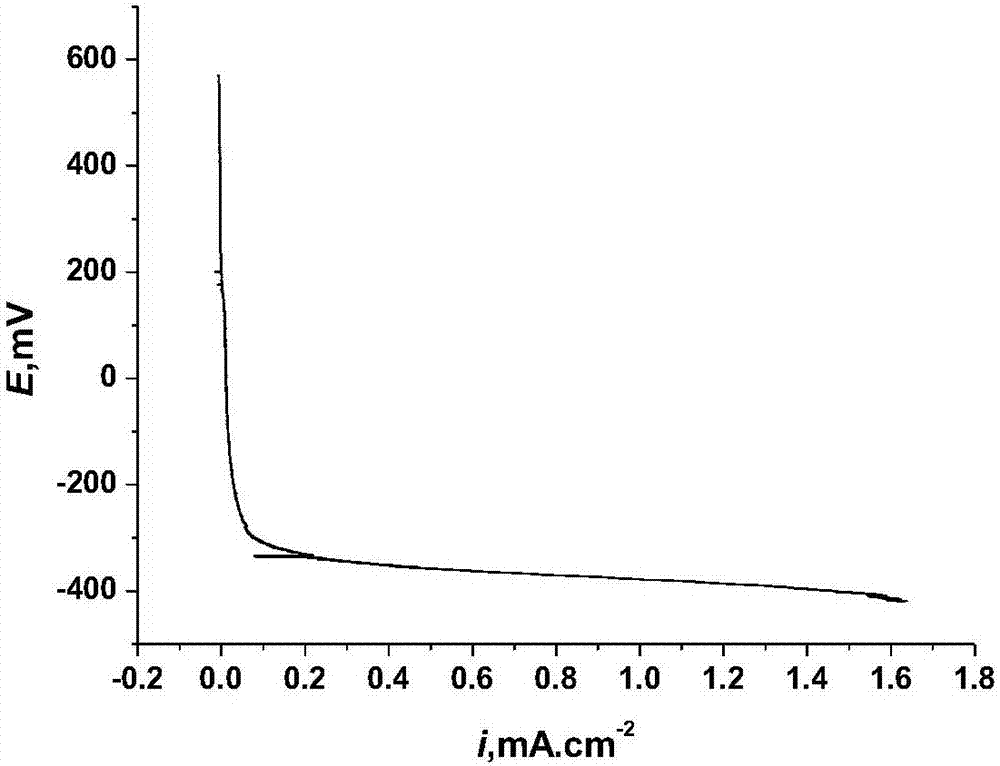

[0047] If the metal corrosion current i is obtained k (unit: μA), the corrosion weight loss rate W can be converted according to Faraday's law corr (unit: g / m 2 h), the formula is as follows:

[0048]

[0049] i corr = i k / s (3)

[0050] Among them: i corr is the metal corrosion current density (unit: μA / cm 2 ),

[0051] M is the gram atomic weight of the metal (u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com