Horizontal drawing extraction process of lithium battery separator

A lithium battery diaphragm and extraction technology, which is applied to lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of time-consuming operation and difficulty, and achieve high slitting utilization rate, good flatness, and fast flattening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

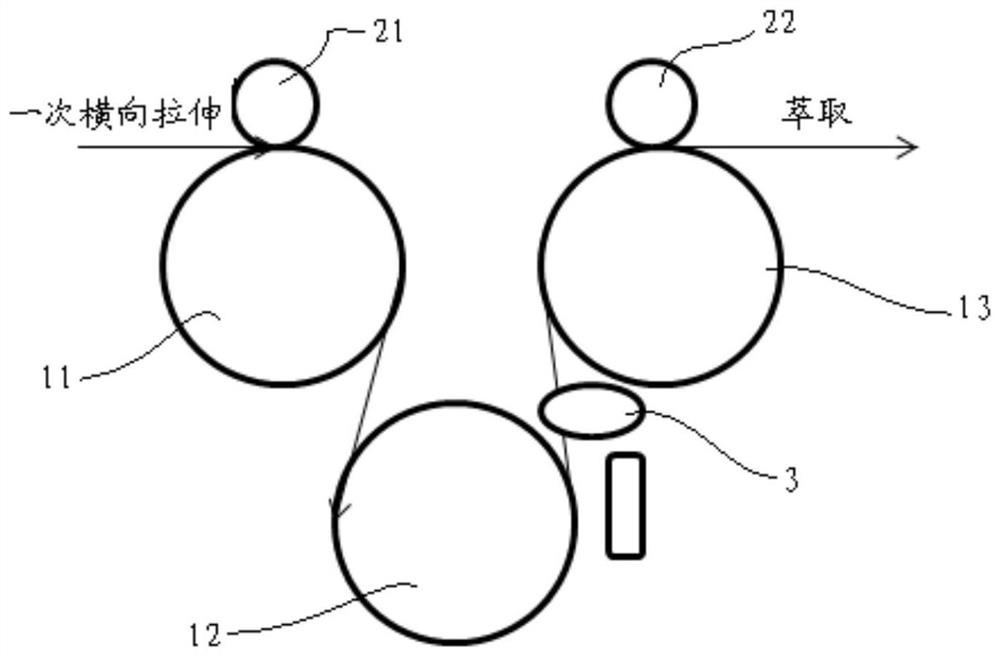

[0019] Refer to attached figure 1 As shown, this embodiment provides a horizontal stretching extraction process for lithium battery separators, which includes sequentially performing a transverse stretching (1TDO) step, an extraction step, and a secondary transverse stretching (2TDO) step. In the first step and the second transverse rope pulling step, the diaphragm is stretched through a plurality of stretching rollers. The diaphragm is firstly stretched multiple times in one transverse stretching step, then pulled into the extraction tank for extraction in the extraction step, and then enters the second transverse stretching step after extraction.

[0020] It should be noted that in the extraction step, before the diap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com