A series-driven planar motor structure and its thrust calculation method

A planar motor, series drive technology, applied in the direction of holding devices and electrical components with magnetic attraction or thrust, can solve the problems of multiple drives, increase the number of coils, increase costs, etc., achieve a simple solution method, increase the amount of calculation, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and embodiments;

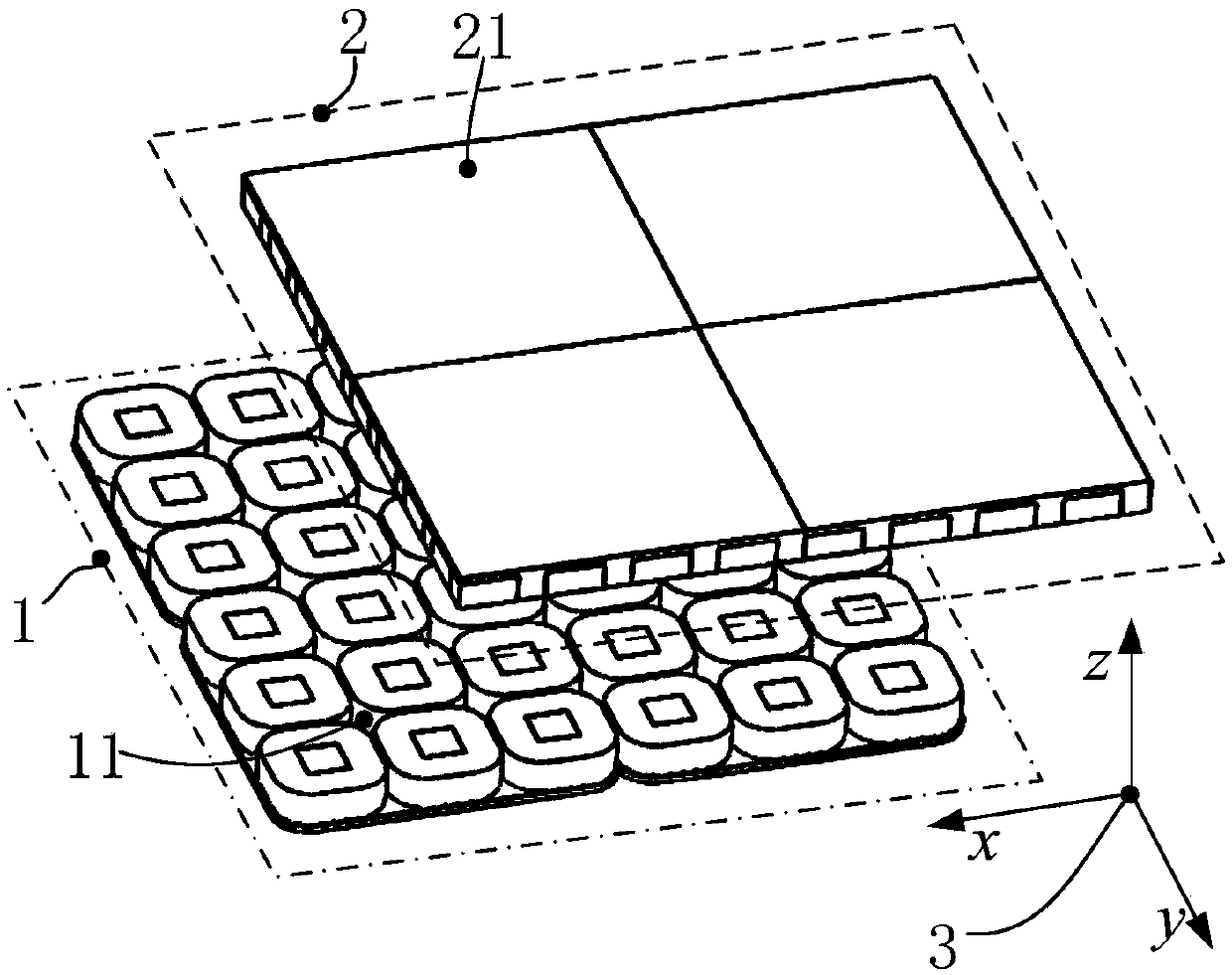

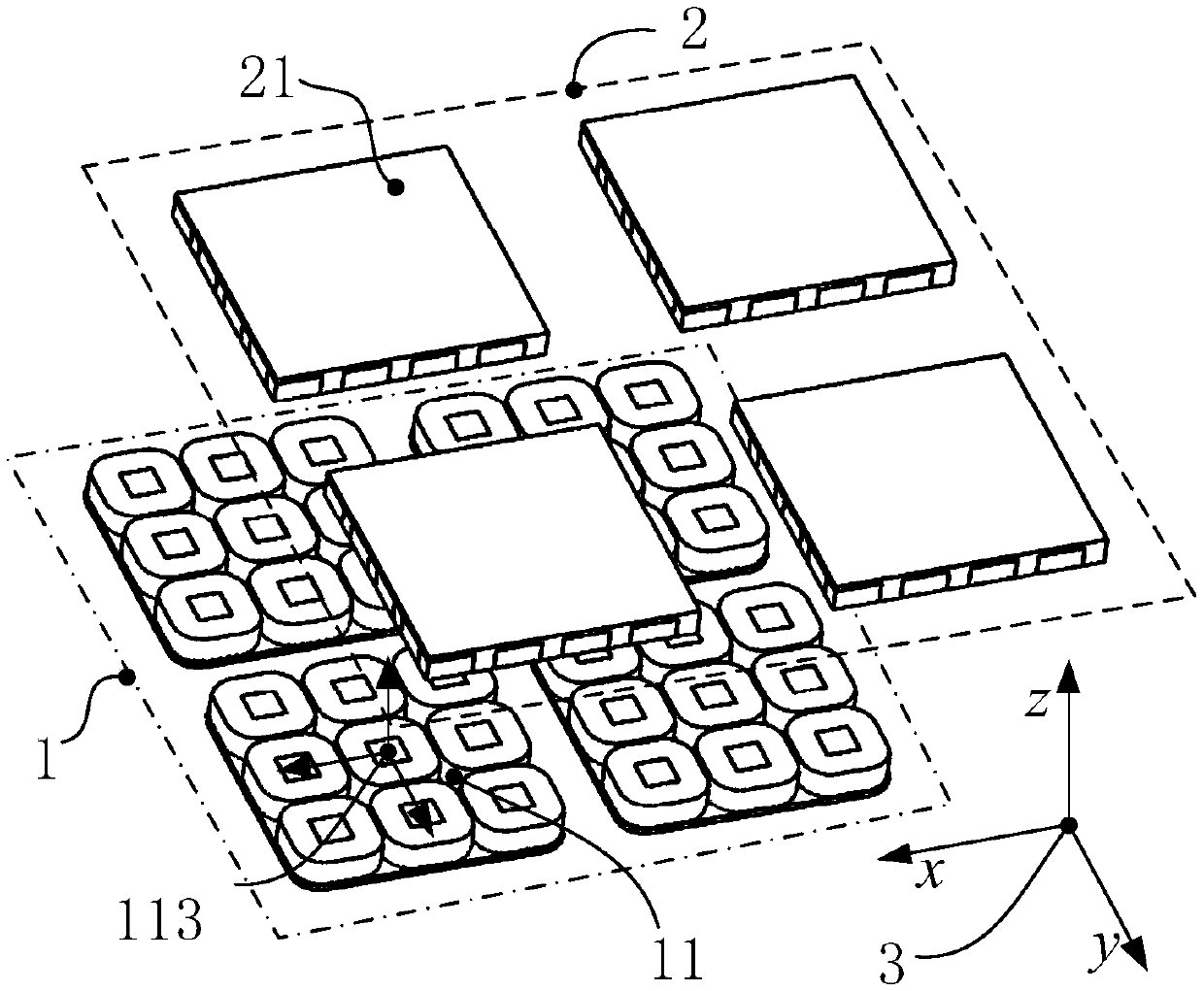

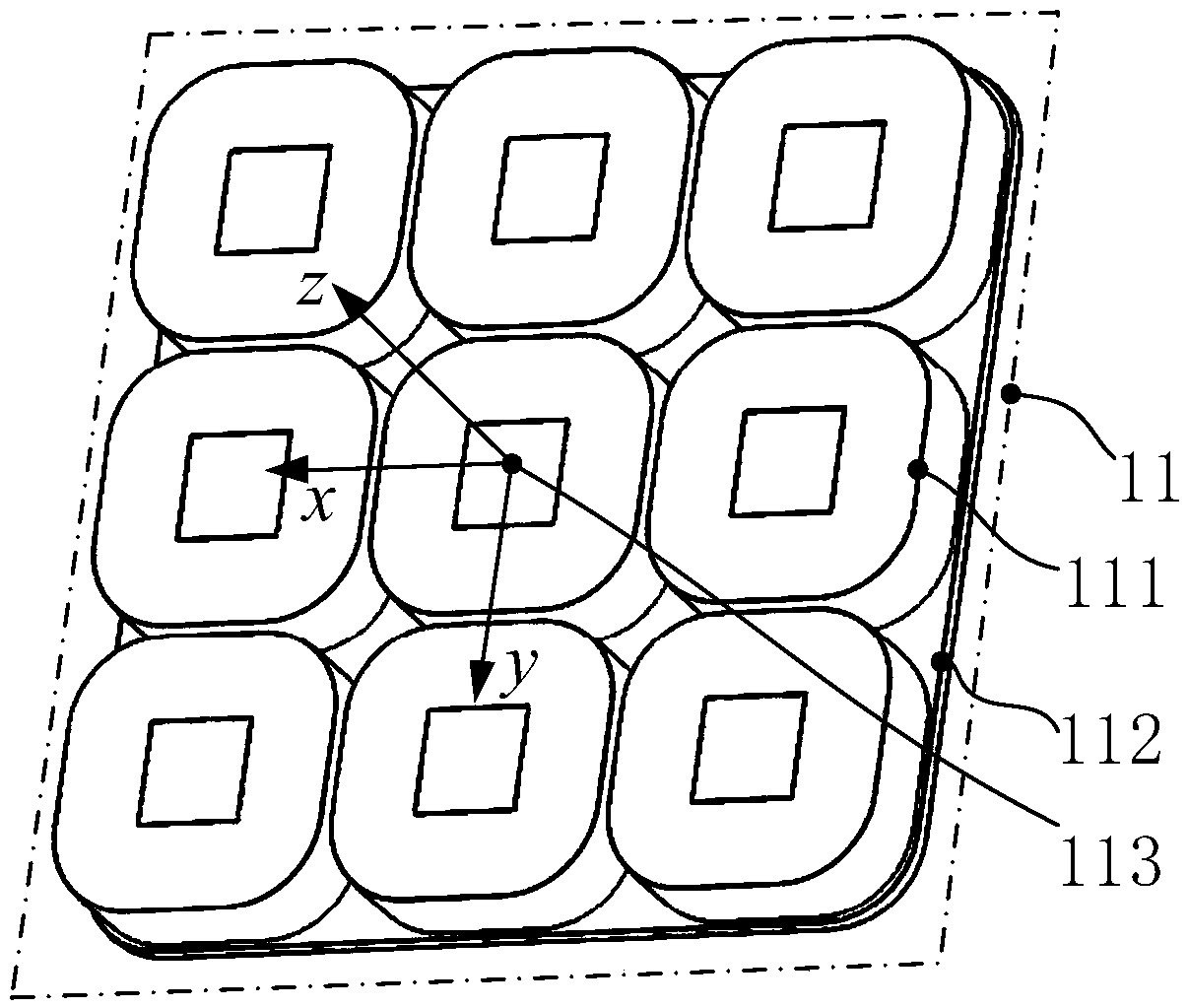

[0061] figure 1 It is a schematic diagram of an embodiment of the planar motor of the present invention, showing the main components of the planar motor, the coil array 1 and the magnetic steel array 2; wherein the coil array 1 is composed of several coil array units 11, and the magnetic steel array 2 It consists of several magnetic steel array units 21, the combination of which is as follows figure 2 As shown; the motor mover is provided with a motor mover coordinate system 3, and the origin of the coordinate system can be but not limited to be located at the geometric center of the motor mover; as Figure 4 The shown coil array unit 11 and the magnetic steel array unit 21 are both equal in size along the x direction, and both are also equal in size along the y direction; as image 3 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com