Preparation method of low-carbon alkane dehydrogenation catalyst

A technology for dehydrogenation catalysts and low-carbon alkanes, applied in the direction of carbon compound catalysts, catalysts, hydrocarbons, etc., can solve the problems of poor catalyst activity, difficult to control the dispersion state of active component chromium, poor catalyst stability, etc., to achieve anti-deposition Effects of improving carbon performance, reducing the amount of B acid, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

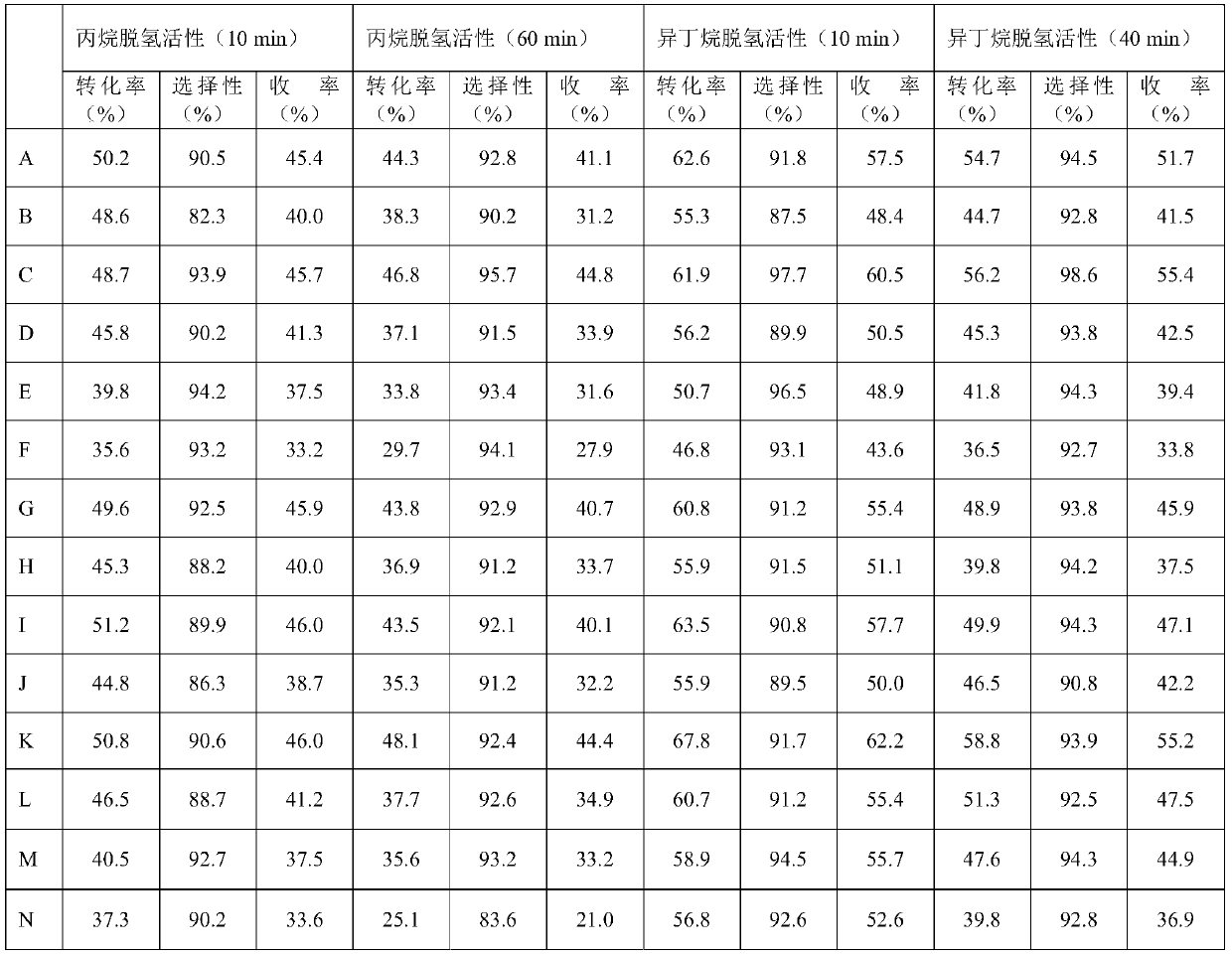

Examples

Embodiment 1

[0036] 2.23g (NH 4 ) 2 Cr 2 o 7 Dissolve in 8ml ethylene glycol, impregnate equal volume into 10g porous γ-Al 2 o 3 in powder. The powder was placed in an oven at 120°C for 4 hours, washed with deionized water, filtered, and dried at 80°C for 2 hours. 0.37gKNO 3 Dissolve in 8ml of deionized water, impregnate equal volume into the above-mentioned treated powder, dry at 80°C for 4 hours, calcined at 680°C for 5 hours, and form and sieve to obtain the catalyst, which is designated as Catalyst A.

Embodiment 2

[0040] 1.77gCrO 3 , 2.48g (NH 4 ) 2 C 2 o 4 Dissolve in 8ml deionized water, impregnate equal volume into 10g porous γ-Al 2 o 3 in powder. The powder was placed in an oven at 60°C for 6 hours, washed with deionized water, filtered, and dried at 100°C for 2 hours. 0.78gCu(NO 3 ) 2 ·3H 2 O, 1.12gFe(NO 3 ) 3 9H 2 O was dissolved in 7ml of deionized water, impregnated into the above-mentioned treated powder with equal volume, dried at 120°C for 3 hours, calcined at 700°C for 6 hours, and the catalyst was obtained by forming and sieving, which was designated as catalyst C.

Embodiment 3

[0044] 1.30gK 2 Cr 2 o 7 Dissolve in 8ml glycerol, impregnate equal volume into 10g porous γ-Al 2 o 3 in powder. The powder was placed in an oven at 140°C for 1 hour, washed with deionized water, filtered, and dried at 80°C for 4 hours. 0.33gNaNO 3 , 0.82gNi(NO 3 ) 2 ·6H 2 O was dissolved in 8ml of deionized water, impregnated into the above-mentioned treated powder with equal volume, dried at 60°C for 6 hours, calcined at 720°C for 4 hours, and the catalyst was obtained by shaping and sieving, which was designated as Catalyst E.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com