Method for automatically cleaning observation window of spray granulator

A technology of spray granulation and automatic cleaning, applied in the field of auxiliary technology, can solve the problems of inconvenient operation, complex structure, complex structure setting, etc., and achieve the effect of fast swing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the drawings and specific preferred embodiments.

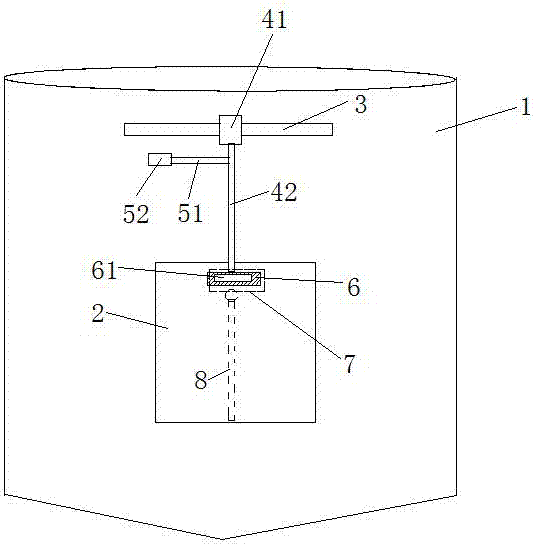

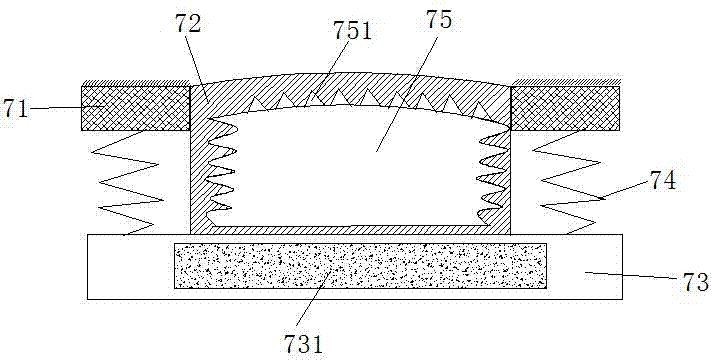

[0035] Such as figure 1 As shown, an automatic cleaning spray granulator includes a spray tower body 1, an observation window 2, a horizontal slide rail 3, a vertical lifting motor 41, a vertical lifting rod 42, a horizontal telescopic rod 51, a lateral telescopic motor 52, and outer Metal slider 6, glass wiper 7, and swing rod 8.

[0036] The observation window is sealed and arranged on the side wall of the spray tower body, and a lighting lamp is also arranged in the spray tower body.

[0037] The horizontal slide rail is arranged on the outer wall surface of the spray tower body directly above the observation window, and is arranged coaxially with the observation window.

[0038] The vertical lifting motor is slidably arranged on the horizontal slide rail, the bottom end of the vertical lifting motor is connected with the top end of the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com