Ultra-precision universal type twist drill

A twist drill and general-purpose technology, applied in twist drills and other directions, can solve the problems of affecting processing accuracy, poor versatility, low production efficiency, etc., and achieve the effects of good versatility, improved accuracy and smoothness, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

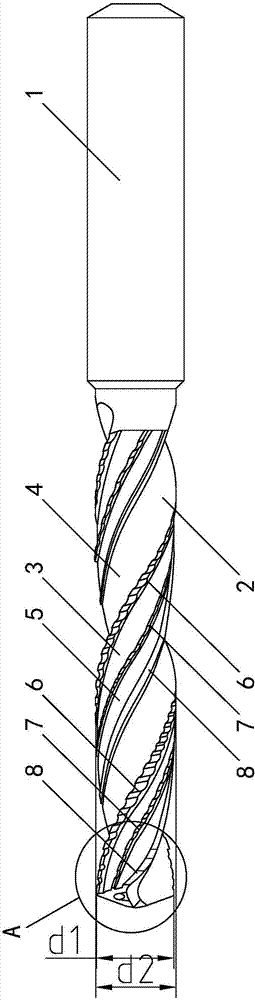

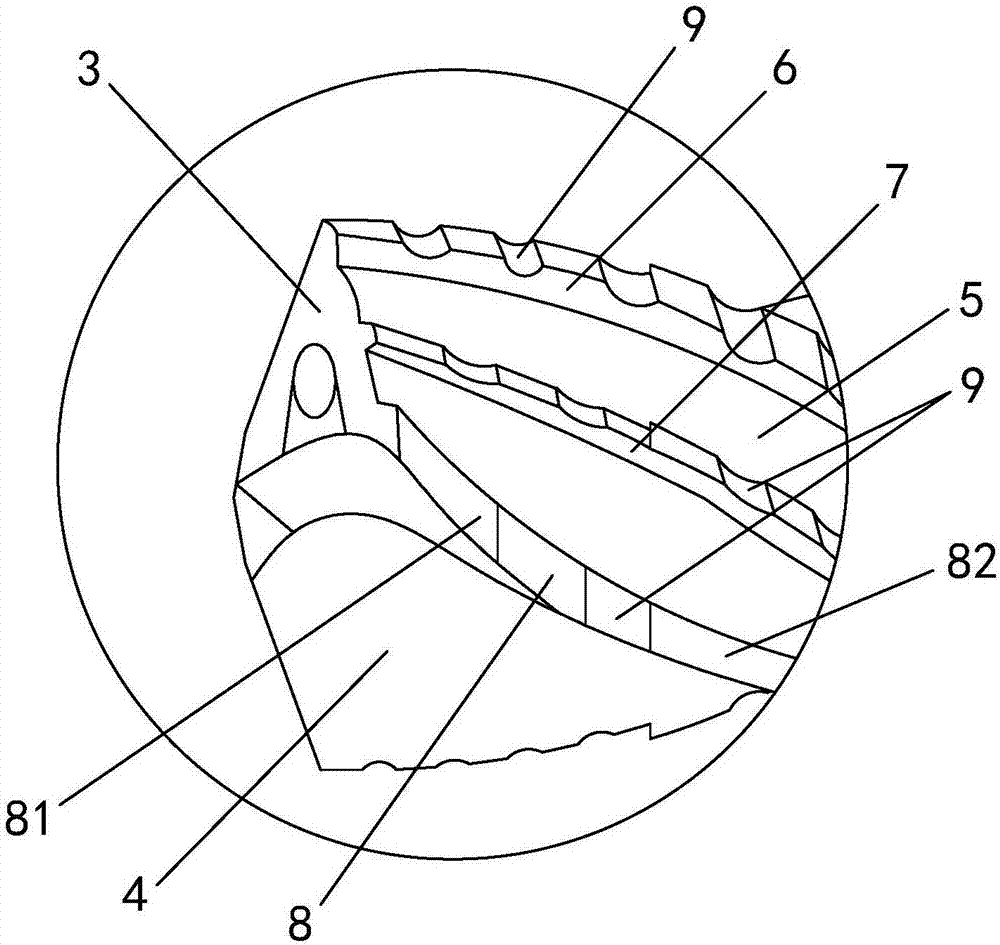

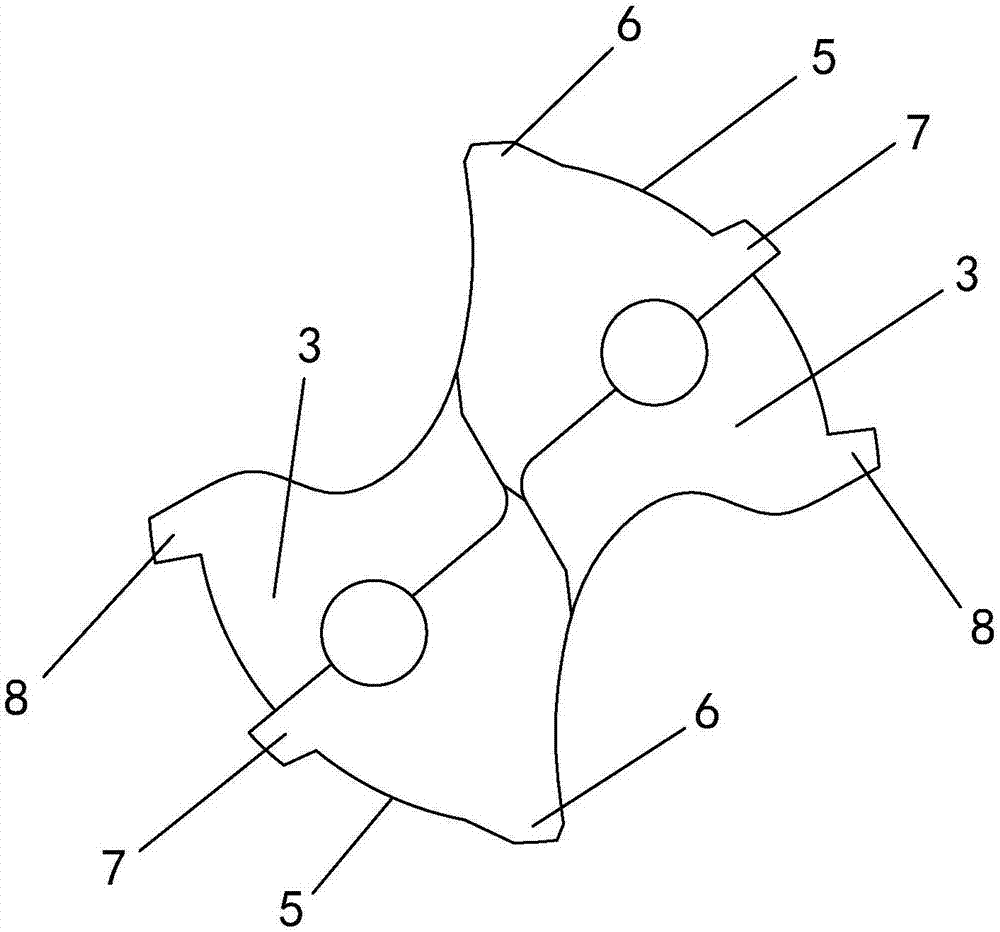

[0026] Example: see attached Figure 1~3 Shown, a kind of ultrafine universal twist drill comprises a shank 1 and a drill bit 2 connected to the front end of the shank; wherein, the drill bit 2 is provided with two blades 3 along the length direction of the twist drill, and two The blades 3 are helically arranged along the circumference of the drill bit 2, and a chip removal groove 4 is provided between the two blades 3; the length of the blade 3 is less than the length of the chip removal groove 4, so as to facilitate chip removal. The two blade lobes 3 are arranged in a helical shape, forming the two chip removal flutes 4 to be opened in a helical shape, and the helical angle is less than 60 degrees.

[0027] The blade backs 5 of the two blades 3 are protrudingly provided with three margins 6-8 along the length direction of the blades 3, and the three margins 6-8 are arranged at intervals, and are divided into sequentially from front to back according to the cutting sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com