Milling tool for carving aluminum alloy wheel

A technology of aluminum alloy and wheels, which is applied in the direction of milling cutters, milling cutting blades, milling machine equipment, etc., can solve the problems of unclear characters on the surface of aluminum alloy wheels, difficult installation, easy breakage, etc., to improve strength and clarity, prevent The effect of breaking and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

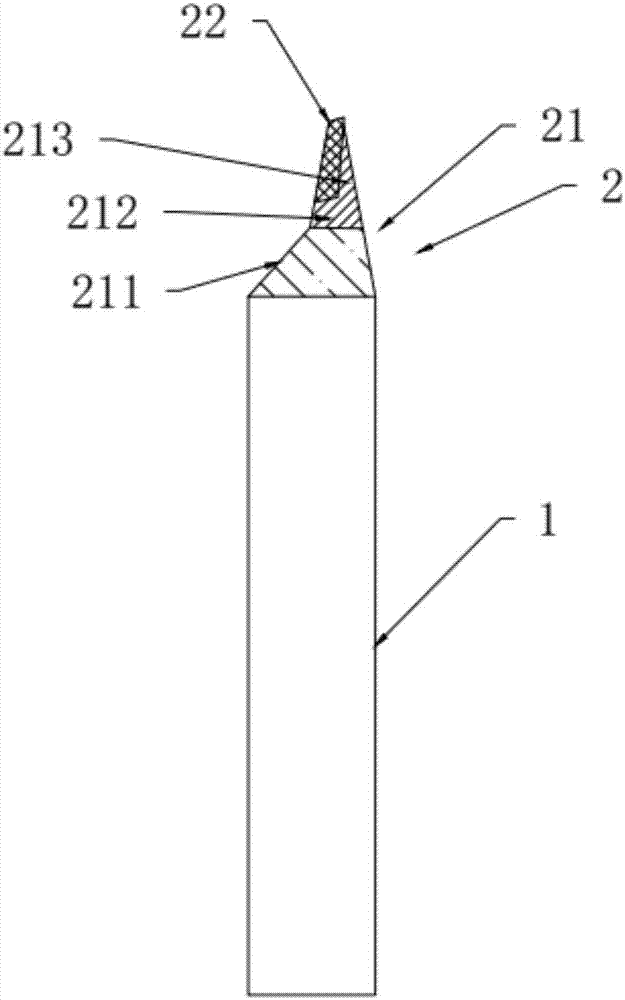

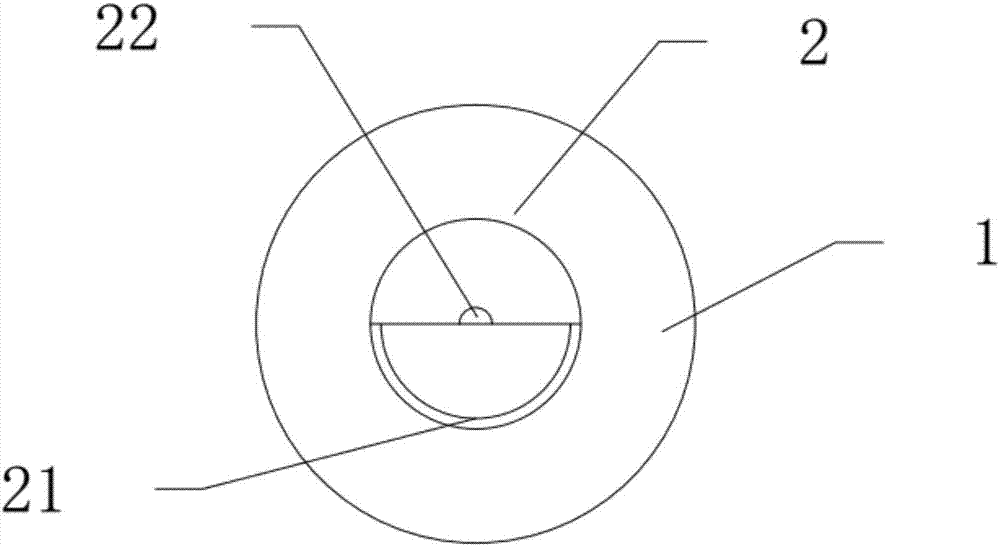

[0031] Such as Figure 1-Figure 2 As shown, a milling cutter for engraving an aluminum alloy wheel includes a handle 1 and a cutter head 2 connected to the handle 1. The end of the cutter head 2 away from the handle 1 is provided with a tip 22, which is made of diamond. , the tip 22 is a semicircular truncated shape, the lower bottom surface of the tip 22 is connected with the handle 1, and the diameter of the upper bottom surface of the tip 22 is 1.0-1.5mm.

[0032] Such as Figure 1-Figure 2 As shown, a connection portion 21 is provided between the handle 1 and the knife tip 22 , and the connection portion 21 includes a base 211 , a support block 212 and a welding portion 213 connected in sequence.

[0033] Such as Figure 1-Figure 2 As shown, the base 211 is in the shape of a truncated cone, and one side with a larger diameter of the base 211 is connected to the handle 1, a support block 212 is connected between the handle 1 and the tip 22, and the side of the welding por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com